Progress of lithology identification technology while drilling

-

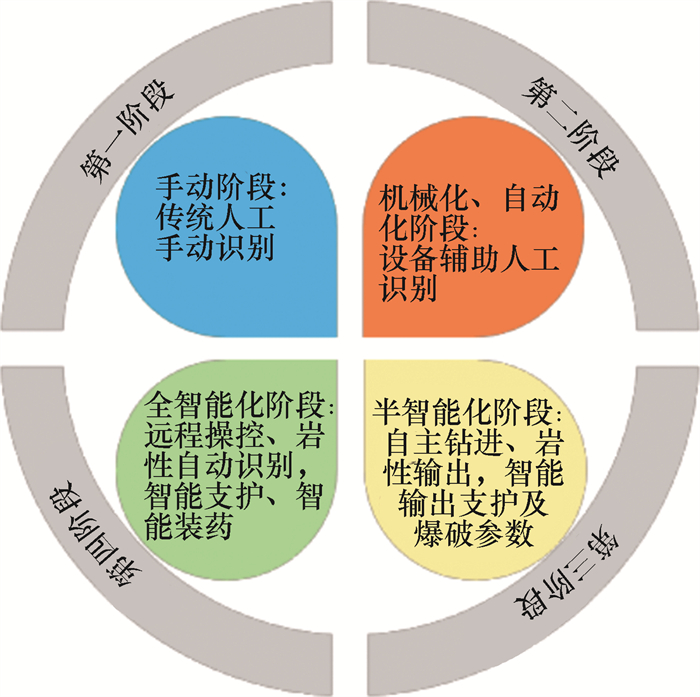

摘要: 随钻岩性识别是一种便捷、高效的地层信息获取技术,具有即时、准确、环保以及节能等优点,可应用于岩石边界确定、支护参数设计、爆破参数设计以及区域地层强度参数识别等工程领域,一直是国内外学者研究的重点方向。本文系统分析了随钻岩性识别技术研究现状以及发展趋势,结合近年来随钻岩性识别技术的应用,探讨了该技术作为智能化探测的新方法与新理论。首先,总结了随钻岩性识别关键技术国内外发展历程;其次,阐述了国内外岩性识别系统的研究现状,包括技术原理及系统组成,并对部分国内外典型岩性识别系统进行对比和评价;再次,总结钻进过程中钻进参数与岩石之间的响应关系及建立的钻进指标和评价体系,并根据旋切式及旋切-冲击式两种钻进方式讨论影响随钻岩性识别的因素;最后,根据随钻岩性识别技术研究领域的发展动态,总结现阶段工程应用中存在的问题,展望随钻岩性识别技术研究未来的发展趋势。Abstract: Lithology identification while in drilling is a convenient and efficient technology to obtain information about formation. It has the advantages of instant, accurate, environmental protection and energy saving. It can be applied to field of engineering such as rock bound aries determination, support parameter design, blast parameter design, and regional formation strength parameter identification. And it has always been the focus of research by scholars in domestic and foreign. This paper systematically analyzes the research status and development trend of lithology identification while in drilling technology, combined with the application of lithology identification while drilling technology in recent years, discusses the technology of lithology identification while drilling as a new method and new theory of intelligent detection. First, the development history of key technologies for lithology identification while drilling in domestic and foreign is summarized. Secondly, it focuses on the research status, including the technical principle and system composition, and compares and evaluates some typical lithology identification systemsin domestic and foreign. Thirdly, the response relationship between the drilling parameters and the rock during the drilling process is summarized, and the established drilling index and evaluation system, and the factors affecting the lithology identification while drilling is discussed according to the two drilling methods of rotary cutting and rotary cutting-impact. Finally, according to the development trend of the research field of lithology identification while drilling technology, the problems existing in the engineering application at this stage are summarized, and the future research of lithology identification while drilling technology is prospected.

-

表 1 国内外随钻技术发展历程

Table 1. Research progress of MWD technology in domestic and foreign

时间 研究进展 国外 国内 20世纪初期 石油工业领域开始运用电法测井技术,称之为随钻测井 未开展 20世纪60年代 随钻测量技术开始广泛研究、应用 未开展 20世纪70年代 采矿工程领域开始应用,主要用于露天开采超前探测地下台阶的岩性 开始独立研究随钻测量技术,针对信号传输问题做出改进 1978年 第一套商业化MWD系统问世,由意大利TELECO公司研发推广 进一步研究、发展随钻测量技术 20世纪80年代 随着计算机不断更新,计算能力增强,随钻测量技术不断发展,众多公司研发出各种型号的MWD系统 大量引进高端随钻装备,同时国产MWD系统开始进行现场试验、小规模生产。如大港定向井公司引进Sperry-sun公司钻井液脉冲随钻仪器后开发了无线测斜系统 20世纪80年代后期 钻井工艺持续改进,随钻测量技术逐渐发展并应用于水平钻井等先进工艺中 水平钻井随钻测量技术引入国内,相关研究逐步完善 20世纪末至21世纪 随钻测量技术进入自动化及人工智能领域,建立数据集成平台,提供实时预测,研发商业化智能凿岩台车 开始发展无线测量技术,引进国外先进MWD系统的同时,国内学者研发国产试验系统,如香港大学DPM系统、山东大学SDT系统等 表 2 国内外随钻测量系统应用情况统计

Table 2. Application Statistics of MWD system in domestic and foreign

时间 系统名称 研发单位 应用方向 监测数据 应用情况 1911年 LWD 国外 石油钻探 电阻率、声速、密度、钻压、扭矩、转速、环空压力、温度 在石油工业领域得到成功应用 1978年 MWD TELECO公司 矿山开采 井斜角、方位角、工具面角、井底钻压、扭矩、转速 在矿山开采工程中得到成功应用 1985年 KYPC 俄罗斯 钻探优化 钻压、钻速、扭矩、转数、升降速度、泵量和泵压等 完成现场试验 1995年 Kajima 日本 地质勘探 钻速、轴压、扭矩、回转频率、钻井液压力与流量 在地质勘探工程中得到成功应用 1999年 ENPASOL Soletanche-Bachy 地质勘探 钻井液流速、转速、推力、扭矩、钻进速度 在地质勘探工程中得到成功应用 2002年 DPM 香港大学 边坡防护 钻头位移、转速、压力、钻进液流量 在边坡防护工程中得到成功应用 2002年 CUG-1 中国地质大学

(武汉)地质勘探 瞬时机械钻速、钻压、转速、扭矩、功率、泵量、泵压 在地质勘探工程中得到成功应用,识别效果良好 2002年 ZCY 山东煤田地质局 地质勘探 钻进回次进尺、孔深、钻压、钻速、立轴转速、立轴扭矩、钻机功率、泵压、泵量、返水量、泥浆密度、pH值 已投入生产应用,可靠性较强、通过部级鉴定 2003年 WZY-1 中国地质大学

(武汉)地质钻探 钻压、功率、扭矩、转速、钻速、孔深进尺、泵压、泵量 实验室试验阶段,识别效果好,安装方便,性能良好 2015年 钻机钻进系统 辽宁工程技术大学 露天矿山爆破 回转压力、加压压力、回转速度、钻进深度、倾斜角度、风压 完成现场试验 2015年 EM-MWD 中国地质大学

(武汉)地质深层勘察 钻进压力、温度、井斜角、方位角 可有效监测井下钻井参数,并通过电磁波信号向地面发送信息 2015年 数字钻进系统 山东大学 岩体力学参数测试 钻进深度、钻进速度、扭矩、压力和转速 在地质勘探工程中得到成功应用 2015年 钻机监测系统 北京矿冶研究总院 露天矿山爆破 钻压、转速、扭矩、钻速、进尺、孔深 在露天爆破工程中得到成功应用 2017年 TRD 山东大学 地下工程围岩稳定性分析及支护设计 钻进速度、钻进压力、转速和扭矩 实验室试验阶段 2017年 A.B.C 美国

Atlas Copco矿山开采 钻压、功率、扭矩、转速、钻速、孔深进尺、泵压 技术先进,现场工程应用良好,设备智能化程度较高 2017年 iSURE 瑞典

Sandvik矿山开采 钻头位移、转速、压力、扭矩 在矿山开采工程中得到成功应用,识别效果良好,商业化产品 2017年 Bever Control 挪威

Bever Control矿山开采 角度、压力、深度、钻进扭矩、钻头转速和钻进速度 设备智能化程度高,技术应用效果明显 2017年 XCY-1 西安理工大学 岩性预测 钻进压力、钻进扭矩、钻头转速和钻进速度 已实现工程应用 2019年 SDT 山东大学 岩性预测 钻进速度、钻头转速、钻进扭矩、钻进推力和钻进深度 实验室试验阶段 2019年 多功能数字钻进测试系统 中国水利水电科学研究院 岩性预测 钻进压强、钻进位移、转速和扭矩 已实现工程应用 -

[1] Schunnesson H. Rock characterisation using percussive drilling[J]. International Journal of Rock Mechanics and Mining Sciences, 1998, 35(6): 711-725. doi: 10.1016/S0148-9062(97)00332-X [2] Messaoud A, Weihs C. Monitoring a deep hole drilling process by nonlinear time series modeling[J]. Journal of Sound and Vibration, 2009, 321(3/4/5): 620-630. [3] Beattie N C M. Monitoring-while-drilling for open-pit mining in a hard rock environment: an investigation of pattern recognition techniques applied to rock identification[D]. Canada: Queen's University 2009. [4] Huang S L, Wang Z W. The mechanics of diamond core drilling of rocks[J]. International Journal of Rock Mechanics and Mining Sciences, 1997, 34(3/4): 612. [5] Schunnesson H, Mozaffari S. Production control and optimization in open pit mining using a drill monitoring system and an image analysis system-A case study from Aitik copper mine in Sweden[J]. Journal of Mines, Metals and Fuels, 2009, 57(9): 244-251. [6] Van Eldert J, Schunnesson H, Saiang D, et al. Improved filtering and normalizing of Measurement-While-Drilling (MWD) data in tunnel excavation[J]. Tunnelling and Underground Space Technology, 2020, 103: 103467. doi: 10.1016/j.tust.2020.103467 [7] 吴昊骏, 纪洪广, 龚敏, 等. 我国地下矿山凿岩装备应用现状与凿岩智能化发展方向[J]. 金属矿山, 2021(1): 185-201, 212. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202101014.htmWu Haojun, Ji Hongguang, Gong Min, et al. Present application status of rock drilling equipment in underground mine and the development direction for intelligent rock drilling in china[J]. Metal Mine, 2021(1): 185-201, 212. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202101014.htm [8] 韩志磊, 张达. 物联网技术在金属矿山的应用思考[J]. 工矿自动化, 2018, 44(5): 1-6. https://www.cnki.com.cn/Article/CJFDTOTAL-MKZD201805001.htmHan Zhilei, Zhang Da. Thinking about application of Internet of things in metal mine[J]. Industry and Mine Automation, 2018, 44(5): 1-6. https://www.cnki.com.cn/Article/CJFDTOTAL-MKZD201805001.htm [9] 丁恩杰, 俞啸, 廖玉波, 等. 基于物联网的矿山机械设备状态智能感知与诊断[J]. 煤炭学报, 2020, 45(6): 2308-2319. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202006036.htmDing Enjie, Yu Xiao, Liao Yubo, et al. Key technology of mine equipment state perception and online diagnosis under Internet of Things[J]. Journal of China Coal Society, 2020, 45(6): 2308-2319. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202006036.htm [10] Galende-Hernández M, Menéndez M, Fuente M J, et al. Monitor-While-Drilling-based estimation of rock mass rating with computational intelligence: The case of tunnel excavation front[J]. Automation in Construction, 2018, 93: 325-338. doi: 10.1016/j.autcon.2018.05.019 [11] Navarro J, Sanchidrián J A, Segarra P, et al. Detection of potential overbreak zones in tunnel blasting from MWD data[J]. Tunnelling and Underground Space Technology, 2018, 82: 504-516. doi: 10.1016/j.tust.2018.08.060 [12] 蔡文军. 机械式无线随钻测斜仪系统研究[D]. 青岛: 中国石油大学, 2007: 6-30. [13] 李泉新. 煤矿井下复合定向钻进及配套泥浆脉冲无线随钻测量技术研究[D]. 北京: 煤炭科学研究总院, 2018: 14-17. [14] 田昊. 隧道地质数字钻进精细化识别方法研究[D]. 济南: 山东大学, 2015: 8-22. [15] 何明明. 基于旋切触探技术的岩体力学参数预报研究[D]. 西安: 西安理工大学, 2017: 3-16. [16] 李骞. 岩石的切削强度特性及岩体力学参数的旋切触探试验研究[D]. 西安: 西安理工大学, 2016: 17-42. [17] Yang W W, Yue Z Q, Tham L G. Automatic monitoring of inserting or retrieving SPT sampler in drillhole[J]. Geotechnical Testing Journal, 2012, 35(3): 103450. doi: 10.1520/GTJ103450 [18] 宋玲, 李宁, 李骞. 软岩的旋转触探参数与力学参数的内在关系研究[J]. 岩石力学与工程学报, 2011, 30(6): 1274-1282. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201106027.htmSong Ling, Li Ning, Li Qian. Study of intrinsic relationship between mechanical parameters and parameters of rotary penetration test of soft rock[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(6): 1274-1282. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201106027.htm [19] Gui M W, Soga K, Bolton M D, et al. Instrumented borehole drilling for subsurface investigation[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2002, 128(4): 283-291. doi: 10.1061/(ASCE)1090-0241(2002)128:4(283) [20] Kahraman S, Bilgin N, Feridunoglu C. Dominant rock properties affecting the penetration rate of percussive drills[J]. International Journal of Rock Mechanics and Mining Sciences, 2003, 40(5): 711-723. doi: 10.1016/S1365-1609(03)00063-7 [21] 曹正林, 周丽清, 王志章, 等. 利用钻井参数进行随钻岩性预测[J]. 天然气工业, 2000, 20(1): 48-50. doi: 10.3321/j.issn:1000-0976.2000.01.012Cao Zhenglin, Zhou Liqing, Wang Zhizhang, et al. Lithology prediction while drilling by use of drilling parameters[J]. Natural Gas Industry, 2000, 20(1): 48-50. doi: 10.3321/j.issn:1000-0976.2000.01.012 [22] 谭卓英, 岳中琦, 蔡美峰. 风化花岗岩地层旋转钻进中的能量分析[J]. 岩石力学与工程学报, 2007, 26(3): 478-483. doi: 10.3321/j.issn:1000-6915.2007.03.006Tan Zhuoying, Yue Zhongqi, Cai Meifeng. Analysis of energy for rotary drilling in weathered granite formation[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(3): 478-483. doi: 10.3321/j.issn:1000-6915.2007.03.006 [23] 谭卓英, 岳中琦, 谭国焕, 等. 金刚石钻进比功及风化花岗岩实时分级研究[J]. 岩石力学与工程学报, 2007, 26(S1): 2907-2912. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2007S1047.htmTan Zhuoying, Yue Zhongqi, Tan Guohuan, et al. Study on specific energy of diamond drilling and real-time classification of weathered granite[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(S1): 2907-2912. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2007S1047.htm [24] 王琦, 秦乾, 高松, 等. 数字钻探随钻参数与岩石单轴抗压强度关系[J]. 煤炭学报, 2018, 43(5): 1289-1295. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201805011.htmWang Qi, Qin Qian, Gao Song, et al. Relationship between rock drilling parameters and rock uniaxial compressive strength based on energy analysis[J]. Journal of China Coal Society, 2018, 43(5): 1289-1295. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201805011.htm [25] Van Eldert J, Funehag J, Saiang D, et al. Rock support prediction based on measurement while drilling technology[J]. Bulletin of Engineering Geology and the Environment, 2021, 80(2): 1449-1465. doi: 10.1007/s10064-020-01957-x [26] Shirkavand M J, Azizi H, Ghasemi I, et al. A correlation between microstructure and rheological properties of broad MWD high-density polyethylene[J]. Iranian Polymer Journal, 2015, 24(11): 953-963. doi: 10.1007/s13726-015-0383-7 [27] El-Kosasy A M, Hussein L A, Salama N N, et al. Kinetic study and peak purity determination of bupropion hydrochloride using RRLC/DAD and HPLC/MWD methods: stability study and application in pharmaceutical preparation and in synthetic mixtures with nicotine[J]. RSC Advances, 2015, 5(79): 64274-64285. doi: 10.1039/C5RA07716H [28] 闫宏亮, 石文龙, 李琳. 随钻测量信息传输方式的发展现状综述研究[J]. 重庆科技学院学报: 自然科学版, 2015, 17(6): 69-72, 83. doi: 10.3969/j.issn.1673-1980.2015.06.018Yan Hongliang, Shi Wenlong, Li Lin. Research on the status and future of the MWD data transmission[J]. Journal of Chongqing University of Science and Technology: Natural Sciences Edition, 2015, 17(6): 69-72, 83. doi: 10.3969/j.issn.1673-1980.2015.06.018 [29] Liu Z W, Song J C. A low-cost calibration strategy for measurement-while-drilling system[J]. IEEE Transactions on Industrial Electronics, 2018, 65(4): 3559-3567. doi: 10.1109/TIE.2017.2752149 [30] Lu C H, Jiang G S, Wang Z Q, et al. The development of and experiments on electromagnetic measurement while a drilling system is used for deep exploration[J]. Journal of Geophysics and Engineering, 2016, 13(5): 824-831. doi: 10.1088/1742-2132/13/5/824 [31] Denney D. Risk management in exploration drilling[J]. Journal of Petroleum Technology, 2000, 52(9): 87-90. doi: 10.2118/0900-0087-JPT [32] Lakshminarayana C R, Tripathi A K, Pal S K. Experimental investigation on potential use of drilling parameters to quantify rock strength[J]. International Journal of Geo-Engineering, 2021, 12(1): 1-15. doi: 10.1186/s40703-020-00130-3 [33] Seibi A, Karrech A, Boukadi F, et al. Wellbore path estimation using measurement while drilling techniques: a comparative study and suggestions for improvements[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2009, 31(14): 1205-1216. doi: 10.1080/15567030802087502 [34] Gui M W, Soga K, Bolton M D, et al. Instrumented borehole drilling for subsurface investigation[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2002, 128(4): 283-291. doi: 10.1061/(ASCE)1090-0241(2002)128:4(283) [35] Yue Z Q, Lee C F, Law K T, et al. Automatic monitoring of rotary-percussive drilling for ground characterization-illustrated by a case example in Hong Kong[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(4): 573-612. doi: 10.1016/j.ijrmms.2003.12.151 [36] SANDVIK Group. Sandvik ming and rock technology[EB/OL]. (2021-09-29)[2021-12-20]. https://www.rocktechnology.sandvik.html [37] Atlas Copco Group. Atlas Copco drilling solutions[A]. Workshop on Technology Development & Mechanisationsof Mines, IHC, New Delhi, 2015. [38] BEVER Control. Bever team online MWD module[EB/OL]. (2021-08-20)[2021-12-20]. https://www.bevercontrol.com/produk-ter//produktinformasjon.html [39] 陈加胜, 邓海顺, 高明中, 等. 掘进巷道顶板岩层随钻识别研究[J]. 采矿与安全工程学报, 2016, 33(2): 271-277. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201602014.htmChen Jiasheng, Deng Haishun, Gao Mingzhong, et al. Study on identification along with drilling of roof strata of excavation roadway[J]. Journal of Mining & Safety Engineering, 2016, 33(2): 271-277. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201602014.htm [40] Wang Q, Gao H K, Jiang B, et al. In-situ test and bolt-grouting design evaluation method of underground engineering based on digital drilling[J]. International Journal of Rock Mechanics and Mining Sciences, 2021, 138: 104575. doi: 10.1016/j.ijrmms.2020.104575 [41] Sugawara J, Yue Z Q, Tham L G, et al. Weathered rock characterization using drilling parameters[J]. Canadian Geotechnical Journal, 2003, 40(3): 661-668. doi: 10.1139/t03-007 [42] Aalizad S A, Rashidinejad F. Prediction of penetration rate of rotary-percussive drilling using artificial neural networks-a case study/Prognozowanie postępu wiercenia przy uzyciu wiertła udarowo-obrotowego przy wykorzystaniu sztucznych sieci neuronowych-studium przypadku[J]. Archives of Mining Sciences, 2012, 57(3): 715-728. doi: 10.2478/v10267-012-0046-x [43] 于恒昌. 基于数字钻探测试技术的岩石力学参数测定方法研究[D]. 济南: 山东大学, 2018. [44] 段云, 熊代余, 徐国权. 钻孔数字化与钻孔岩性自动识别技术[J]. 金属矿山, 2015(10): 125-129. doi: 10.3969/j.issn.1001-1250.2015.10.027Duan Yun, Xiong Daiyu, Xu Guoquan. A new technology for digital drilling and automatic lithology identification[J]. Metal Mine, 2015(10): 125-129. doi: 10.3969/j.issn.1001-1250.2015.10.027 [45] 王玉杰, 佘磊, 赵宇飞, 等. 基于数字钻进技术的岩石强度参数测定试验研究[J]. 岩土工程学报, 2020, 42(9): 1669-1678. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202009017.htmWang Yujie, She Lei, Zhao Yufei, et al. Experimental study on measurement of rock strength parameters based on digital drilling technology[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(9): 1669-1678. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202009017.htm [46] 朱海成, 韩新平, 冀常鹏, 等. 钻孔岩性识别条件下的数字爆破技术研究[J]. 煤炭科学技术, 2018, 46(10): 184-189. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201810029.htmZhu Haicheng, Han Xinping, Ji Changpeng, et al. Research on digital blasting technique with lithology identification of borehole[J]. Coal Science and Technology, 2018, 46(10): 184-189. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201810029.htm [47] He M M, Li N, Zhang Z Q, et al. An empirical method for determining the mechanical properties of jointed rock mass using drilling energy[J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 116: 64-74. doi: 10.1016/j.ijrmms.2019.03.010 [48] Wang L, Zhang C X, Lin T, et al. Characterization of a fiber optic gyroscope in a measurement while drilling system with the dynamic Allan variance[J]. Measurement, 2015, 75: 263-272. doi: 10.1016/j.measurement.2015.05.001 [49] 谭卓英. 岩土工程界面识别理论与方法[M]. 北京: 科学出版社, 2008. [50] Yu B S, Zhang K, Niu G G, et al. Real-time rock strength determination based on rock drillability index and drilling specific energy: an experimental study[J]. Bulletin of Engineering Geology and the Environment, 2021, 80(5): 3589-3603. doi: 10.1007/s10064-021-02154-0 [51] Yang P, Zhang Y, Wang H B. Optimization and establishment of drillability in gravel formation[J]. IOP Conference Series: Earth and Environmental Science, 2020, 570(3): 032018. doi: 10.1088/1755-1315/570/3/032018 [52] Shi X C, Wu J, Gao L Y, et al. Evaluation methods and standards for rock drillability in oil and gas drilling engineering in China: a review[J]. IOP Conference Series: Earth and Environmental Science, 2020, 570(3): 032057. doi: 10.1088/1755-1315/570/3/032057 [53] Lakshminarayana C R, Tripathi A K, Pal S K. Rock strength characterization using measurement while drilling technique[J]. Indian Geotechnical Journal, 2020, 50(6): 994-1005. doi: 10.1007/s40098-020-00441-3 [54] Liu H, Karen Yin K. Analysis and interpretation of monitored rotary blasthole drill data[J]. International Journal of Surface Mining, Reclamation and Environment, 2001, 15(3): 177-203. doi: 10.1076/ijsm.15.3.177.3410 [55] 董方政. 基于钻孔过程监测(DPM)的岩石可钻性评价[D]. 北京: 中国地质大学(北京), 2019. [56] Abdullaevna Kudaikulova G. The relationship of the density and consumption of drilling mud with a model of rock drillability[J]. American Journal of Engineering and Technology Management, 2019, 4(1): 5. doi: 10.11648/j.ajetm.20190401.12 [57] Mao S, Shi X C, Meng Y F, et al. Experimental investigation of rock drillability for three rock types under varying wellbore pressure conditions[J]. Rock Mechanics and Rock Engineering, 2018, 51(8): 2439-2445. doi: 10.1007/s00603-018-1472-7 [58] Drumheller D S. Attenuation of sound waves in drill strings[J]. The Journal of the Acoustical Society of America, 1993, 94(4): 2387-2396. doi: 10.1121/1.407458 [59] Teale R. The concept of specific energy in rock drilling[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1965, 2(1): 57-73. [60] Lee S, Park B, Kim Y, et al. Peak detection with pile-up rejection using multiple-template cross-correlation for MWD (measurement while drilling)[C]//Robot Intelligence Technology and Applications, 2015: 753-758. [61] Jain A K, Singh D P. Specific energy as a criterion for drillability of rocks-A laboratory study[M]//Geotechnical Instrumentation and Monitoring in Open Pit and Underground Mining. CRC Press, 2020: 253-263. [62] 闫铁, 李玮, 毕雪亮, 等. 旋转钻井中岩石破碎能耗的分形分析[J]. 岩石力学与工程学报, 2008, 27(S2): 3649-3654. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2008S2056.htmYan Tie, Li Wei, Bi Xueliang, et al. Fractal analysis of energy consumption of rock fragmentation in rotary drilling[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(S2): 3649-3654. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2008S2056.htm [63] 曹钧, 沈志康, 胡永乐, 等. 冲击作用下岩石破碎比功理论分析及模糊预测模型[J]. 岩土力学, 2012, 33(S2): 145-149. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2012S2021.htmCao Jun, Shen Zhikang, Hu Yongle, et al. Theoretic analysis of specific power of broken hard rock by impact action and its fuzzy prediction model[J]. Rock and Soil Mechanics, 2012, 33(S2): 145-149. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2012S2021.htm [64] 谭卓英, 蔡美峰, 岳中琦, 等. 基于岩石可钻性指标的地层界面识别理论与方法[J]. 北京科技大学学报, 2006, 28(9): 803-807. doi: 10.3321/j.issn:1001-053X.2006.09.001Tan Zhuoying, Cai Meifeng, Yue Zhongqi, et al. Theory and approach of identification of ground interfaces based on rock drillability index[J]. Journal of University of Science and Technology Beijing, 2006, 28(9): 803-807. doi: 10.3321/j.issn:1001-053X.2006.09.001 [65] 卢勇. 智能双管钻机的岩性识别以及钻具磨损识别[D]. 沈阳: 东北大学, 2017. [66] Bauer A. Open pit drilling and blasting[J]. Journal of the Southern African Institute of Mining and Metallurgy, 1971, 71(6): 115-121. [67] Yin K, Liu H. Using information extracted from drill data to improve blasting design and fragmentation[J]. Fragblast, 2001, 5(3): 157-179. doi: 10.1076/frag.5.3.157.7384 [68] Darbor M, Faramarzi L, Sharifzadeh M. Performance assessment of rotary drilling using non-linear multiple regression analysis and multilayer perceptron neural network[J]. Bulletin of Engineering Geology and the Environment, 2019, 78(3): 1501-1513. doi: 10.1007/s10064-017-1192-3 [69] Yarali O, Kahraman S. The drillability assessment of rocks using the different brittleness values[J]. Tunnelling and Underground Space Technology, 2011, 26(2): 406-414. doi: 10.1016/j.tust.2010.11.013 [70] Chen J, Yue Z Q. Weak zone characterization using full drilling analysis of rotary-percussive instrumented drilling[J]. International Journal of Rock Mechanics and Mining Sciences, 2016, 89: 227-234. doi: 10.1016/j.ijrmms.2016.09.012 [71] Kalantari S, Baghbanan A, Hashemalhosseini H. An analytical model for estimating rock strength parameters from small-scale drilling data[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2019, 11(1): 135-145. doi: 10.1016/j.jrmge.2018.09.005 [72] Wang Q, Gao H K, Jiang B, et al. Research on an evaluation method for the strength of broken coal mass reinforced by cement slurry based on digital drilling test technology[J]. Bulletin of Engineering Geology and the Environment, 2019, 78(6): 4599-4609. doi: 10.1007/s10064-018-1402-7 [73] 曹瑞琅, 王玉杰, 赵宇飞, 等. 基于钻进过程指数定量评价岩体完整性原位试验研究[J]. 岩土工程学报, 2021, 43(4): 679-687. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202104013.htmCao Ruilang, Wang Yujie, Zhao Yufei, et al. In-situ tests on quantitative evaluation of rock mass integrity based on drilling process index[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(4): 679-687. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202104013.htm [74] Ligtenberg J H, Wansink A G. Neural network prediction of permeability in the el garia formation, ashtart oilfield, offshore Tunisia[J]. Journal of Petroleum Geology, 2001, 24(4): 389-404. doi: 10.1111/j.1747-5457.2001.tb00682.x [75] 苏永华. 岩土参数模糊隶属函数的构造方法及应用[J]. 岩土工程学报, 2007, 29(12): 1772-1779. doi: 10.3321/j.issn:1000-4548.2007.12.005Su Yonghua. Constructing method of fuzzy membership function of geotechnical parameters and its application[J]. Chinese Journal of Geotechnical Engineering, 2007, 29(12): 1772-1779. doi: 10.3321/j.issn:1000-4548.2007.12.005 [76] Singh T, Gosain A. Comparison of different fuzzy clustering algorithms: a replicated case study[C]//Information and Decision Sciences, 2018: 267-275. [77] Wolf M, Pelissier-Combescure J. Faciolog-automatic electrofaci-es determination[C]//SPWLA 23rd Annual Logging Symposium. OnePetro, 1982. [78] Doveton J H. Geologic log analysis using computer methods: American association of petroleum geologists[J]. Computer Applications in Geology, 1994, 2: 1-22. [79] Busch J M, Fortney W G, Berry L N. Determination of lithology from well logs by statistical analysis[J]. SPE Formation Evaluation, 1987, 2(4): 412-418. doi: 10.2118/14301-PA [80] Yao Z H, Wu L D. A clustering approach based on Marr's operator with its application to lithologic recognition[J]. Pattern Recognition Letters, 1991, 12(8): 451-456. doi: 10.1016/0167-8655(91)80008-X [81] 邱颖, 孟庆武, 李梯, 等. 神经网络用于岩性及岩相预测的可行性分析[J]. 地球物理学进展, 2001, 16(3): 76-84. doi: 10.3969/j.issn.1004-2903.2001.03.010Qin Ying, Meng Qingwu, Li Ti, et al. The feasibility analysis of neural network in the prediction of lithology and lithofacles[J]. Progress in Geophysics, 2001, 16(3): 76-84. doi: 10.3969/j.issn.1004-2903.2001.03.010 [82] 张洪, 邹乐君, 沈晓华. BP神经网络在测井岩性识别中的应用[J]. 地质与勘探, 2002, 38(6): 63-65. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT200206015.htmZhang Hong, Zou Lejun, Shen Xiaohua. The application of bp neural network in well lithology identification[J]. Geology and Prospecting, 2002, 38(6): 63-65. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT200206015.htm [83] 张幼振, 张宁, 邵俊杰, 等. 基于钻进参数聚类的含煤地层岩性模糊识别[J]. 煤炭学报, 2019, 44(8): 2328-2335. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201908007.htmZhang Youzhen, Zhang Ning, Shao Junjie, et al. Fuzzy identification of coal-bearing strata lithology based on drilling parameter clustering[J]. Journal of China Coal Society, 2019, 44(8): 2328-2335. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201908007.htm [84] 张乐文, 张德永, 李术才, 等. 基于粗糙集理论的遗传-RBF神经网络在岩爆预测中的应用[J]. 岩土力学, 2012, 33(S1): 270-276. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2012S1044.htmZhang Lewen, Zhang Deyong, Li Shucai, et al. Application of RBF neural network to rockburst prediction based on rough set theory[J]. Rock and Soil Mechanics, 2012, 33(S1): 270-276. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2012S1044.htm [85] Zhang X S, Zhang H X, Guo J S, et al. Auto measurement while drilling mud pulse signal recognition based on deep neural network[J]. Journal of Petroleum Science and Engineering, 2018, 167: 37-43. doi: 10.1016/j.petrol.2018.04.004 [86] Kumar B R, Vardhan H, Govindaraj M. Estimating rock properties using sound level during drilling: field investigation[J]. International Journal of Mining and Mineral Engineering, 2010, 2(3): 169. doi: 10.1504/IJMME.2010.037618 [87] Kumar B R, Vardhan H, Govindaraj M. Prediction of uniaxial compressive strength, tensile strength and porosity of sedimentary rocks using sound level produced during rotary drilling[J]. Rock Mechanics and Rock Engineering, 2011, 44(5): 613-620. doi: 10.1007/s00603-011-0160-7 [88] Kumar V, Vardhan H, Murthy C S N. Quantification of rock properties using frequency analysis during diamond core drilling operations[J]. Journal of the Institution of Engineers: India: Series D, 2019, 100(1): 67-81. doi: 10.1007/s40033-019-00174-5 [89] Kumar V, Vardhan H, Murthy C S N. Multiple regression model for prediction of rock properties using acoustic frequency during core drilling operations[J]. Geomechanics and Geoengineering, 2020, 15(4): 297-312. doi: 10.1080/17486025.2019.1641631 [90] Ivaničová L, Futó J, Krepelka F. Acoustic and physiological effects of the surroundings in rock cutting process[J]. Acta Montanistica Slovaca, 2010, 15(3): 220-224. [91] Shreedharan S, Hegde C, Sharma S, et al. Acoustic fingerprinting for rock identification during drilling[J]. International Journal of Mining and Mineral Engineering, 2014, 5(2): 89-105. doi: 10.1504/IJMME.2014.060193 [92] Vardhan H, Adhikari G R, Govinda R M. Estimating rock properties using sound levels produced during drilling[J]. International Journal of Rock Mechanics and Mining Sciences, 2009, 46(3): 604-612. doi: 10.1016/j.ijrmms.2008.07.011 [93] 李辉, 谢平, 杨文飞, 等. 随钻钻柱振动声波技术对塔北地区风化壳的识别[J]. 录井工程, 2014, 25(3): 10-14, 99. doi: 10.3969/j.issn.1672-9803.2014.03.003Li Hui, Xie Ping, Yang Wenfei, et al. Vibro-acoustic while drilling technique for identifying the weathering crust in northern Tarim Basin[J]. Mud Logging Engineering, 2014, 25(3): 10-14, 99. doi: 10.3969/j.issn.1672-9803.2014.03.003 [94] 李占涛, 林小国, 宋春霞. 岩石钻孔振动与声波频谱特性实验研究[J]. 地下空间与工程学报, 2019, 15(4): 1008-1016. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE201904006.htmLi Zhantao, Lin Xiaoguo, Song Chunxia. Experimental study on spectral characteristics of sound and vibrations in rock drilling[J]. Chinese Journal of Underground Space and Engineering, 2019, 15(4): 1008-1016. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE201904006.htm [95] Futó J, Krepelka F, Chlebová Z, et al. Measuring procedure of experimental data acquisition and data evaluation of acoustic emission in rock disintegration[J]. Acta Montanistica Slovaca, 2009, 14(3): 254. [96] Miklúšová V, Ušlová L, Ivaničová L, et al. Acoustic signal-new feature in monitoring of rock disintegration process[J]. Contributions to geophysics and geodesy, 2006, 36: 125-133. [97] Mainjot A K, Schajer G S, Vanheusden A J, et al. Influence of cooling rate on residual stress profile in veneering ceramic: measurement by hole-drilling[J]. Dental Materials, 2011, 27(9): 906-914. doi: 10.1016/j.dental.2011.05.005 [98] Rodgers M, McVay M, Horhota D, et al. Assessment of rock strength from measuring while drilling shafts in Florida limestone[J]. Canadian Geotechnical Journal, 2018, 55(8): 1154-1167. doi: 10.1139/cgj-2017-0321 [99] 王国法, 任怀伟, 庞义辉, 等. 煤矿智能化(初级阶段)技术体系研究与工程进展[J]. 煤炭科学技术, 2020, 48(7): 1-27. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202007001.htmWang Guofa, Ren Huaiwei, Pang Yihui, et al. Research and engineering progress of intelligent coal mine technical system in early stages[J]. Coal Science and Technology, 2020, 48(7): 1-27. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202007001.htm [100] 闫铁, 许瑞, 刘维凯, 等. 中国智能化钻井技术研究发展[J]. 东北石油大学学报, 2020, 44(4): 15-21, 6. doi: 10.3969/j.issn.2095-4107.2020.04.003Yan Tie, Xu Rui, Liu Weikai, et al. Research and development of intelligent drilling technology in China[J]. Journal of Northeast Petroleum University, 2020, 44(4): 15-21, 6. doi: 10.3969/j.issn.2095-4107.2020.04.003 -

下载:

下载: