Preparation, classification, hydration mechanism and durability of magnesium-based cementing material

-

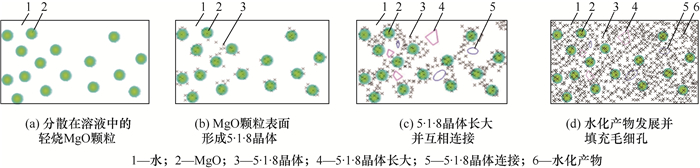

摘要: 镁质胶凝材料是基于活性MgO的一种新型胶凝材料,具有快凝、早强、耐火等特性,在修补、抢修等工程中具有显著优势。本文按照MgO煅烧温度及调和液种类,将镁质胶凝材料分为氯氧镁水泥、硫氧镁水泥和磷酸镁水泥,详细讨论并总结了它们的水化机理及耐久性能。氯氧镁水泥的水化实质是MgO、MgCl2和H2O三元体系水化;硫氧镁水泥水化过程由于游离MgSO4的存在导致硬化体系的强度较低;磷酸镁水泥由于MgO溶解放热及与磷酸盐之间剧烈反应放热的重叠导致水泥水化过快及放热过于集中。碳化会收缩镁质胶凝材料硬化基体中的毛细孔、优化内部孔结构,提高其强度及耐久性。镁质胶凝材料耐水性都较差,氯氧镁水泥耐水性差的原因目前并没有统一的认识;硫氧镁水泥耐水性差是因为未反应的MgO与水反应生成Mg(OH)2,引起体积膨胀、硬化基体开裂;磷酸镁水泥耐水性差是因为磷酸盐会导致水化产物及未反应的MgO溶解。Abstract: Magnesium-based cementing material is a new type of cementitious material based on active MgO. It features rapid solidification, early strength and fire resistance, exhibiting significant advantages in repair and emergency repair projects. This study divided magnesium-based cementitious materials into three types according to the differences in calcination temperature of MgO and blending solution : magnesium oxychloride cement, magnesium oxysulfate cement, magnesium phosphate cement. We conducted detailed discussion and review of their hydration mechanism and durability. The hydration of magnesium oxychloride cement lies in the hydration of ternary system of MgO, MgCl2 and H2O. The hardened system of magnesium oxysulfate cement shows low strength due to the existence of free MgSO4 in the hydration process. The hydration rate of magnesium phosphate cement delayed owing to the overlapping of exothermic of MgO solution and sharp reaction between MgO and phosphate, which leads to excessive hydration and over-concentrated heat release. Carbonation reduces the pores contents, optimizes the internal pore structure, and improves the strength and durability of magnesium-based cementitious materials. The magnesium-based cementitious materials have poor water resistance, among which no unified understanding has been reached as to the reasons for magnesium oxychloride cement. For magnesium oxysulfate cement, the unreacted MgO reacts with water to form Mg(OH)2, and the volume expansion leads to the cracking of the hardened matrix. In the case of magnesium phosphate cement, the phosphate can lead to the dissolution of hydration products and unreacted MgO.

-

表 1 氯氧镁水泥水化产物组成、形貌及性能

Table 1. Composition, morphology and properties of hydration products of magnesium oxychloride cement

相 组成 形貌 性能 2相 2Mg(OH)2·MgCl2·4H2O或2Mg(OH)2·MgCl2·2H2O 温度超过100 ℃时保持稳定 易碳化 3相 Mg2(OH)3Cl4·4H2O或3Mg(OH)2·MgCl2·8H2O 针状/棒状,在100 ℃以下保持稳定 耐水性差 5相 Mg3(OH)5Cl4·4H2O或5Mg2(OH)2·MgCl2·8H2O 针状/棒状,在100 ℃以下保持稳定 耐水性差 9相 9Mg(OH)2·MgCl2·5H2O 温度超过100 ℃时保持稳定 易碳化 表 2 硫氧镁水泥水化机理

Table 2. Hydration mechanism of magnesium oxysulfide cement

水化阶段 水化反应 水化结果 第一阶段:诱导前期(水化时间:0~0.8 h) MgO表面形成一层水化膜并释放出大量OH-,使MgO与H2O的接触面积减小 反应速率迅速下降 第二阶段:诱导期(水化时间:0.80~12.00 h) MgO的水化放热速度下降,水化膜与上一阶段所产生的OH-离子发生反应 浆体中的pH值缓慢增加 第三阶段:加速期(水化时间:12.00~23.25 h) 诱导期水化的OH-增加到一定浓度,镁络合层会与其反应,生成5·1·7晶核。5·1·7晶核的水化结晶会破坏包裹MgO表面的络合镁层 抑制Mg(OH)2的形成,使水化向着5·1·7相结晶方向进行 第四阶段:减速期(水化时间:23.25~30.51 h) 5·1·7晶核结晶长大,浆体离子浓度降低 水化速率逐渐下降 第五阶段:稳定期(水化时间:30.51 h) 未反应的氧化镁越来越少,同时浆体中离子浓度不断降低 5·1·7晶核的结晶生成减缓 表 3 不同M/P(MgO/H2PO4-)下pH值和水化产物

Table 3. The pH values and final hydration products of MPC at different M/P ratio

M/P pH值 水化产物 <0.64 4.3~7.4 MgHPO4·3H2O 0.64~0.67 7.4~8.5 MgHPO4·3H2O、Mg2KH(PO4)2·15H2O 0.67~1 8.5~12.1 KMgPO4·6H2O、Mg2KH(PO4)2·15H2O >1 12.1 KMgPO4·6H2O 表 4 矿物掺合料对磷酸镁水泥水化热、凝结时间的影响

Table 4. Influence of mineral admixtures on hydration heat and setting time of MPC

表 5 矿物掺合料对磷酸镁水泥抗水性与抗压强度的影响

Table 5. Influence of mineral admixtures on water resistance and compressive strength of MPC

矿物掺合料 取代方式 取代比例/% 浸水时间/d 强度保留率/% 影响 钢渣 MgO 20 60 >90 改善 镍铁渣 MgO 40 60 >100 改善 偏高岭土 MgO 45 28 >90 改善 矿渣 MgO+KDP 10 60 >100 改善 粉煤灰 MgO 30 28 < 80 减弱 MgO+KDP 30 28 >90 改善 粉煤灰、硅灰复合 MgO+KDP 15 56 >90 改善 10 表 6 氯氧镁水泥耐久性提升

Table 6. Durability improvement of magnesium oxychloride cement

表 7 硫氧镁水泥耐久性提升手段与方法

Table 7. Methods for improving the durability of magnesium oxysulfate cement

-

[1] Van Damme H. Concrete material science: past, present, and future innovations[J]. Cement and Concrete Research, 2018, 112: 5-24. doi: 10.1016/j.cemconres.2018.05.002 [2] Liu Z, Guan D B, Wei W, et al. Reduced carbon emission estimates from fossil fuel combustion and cement production in China[J]. Nature, 2015, 524(7565): 335-338. doi: 10.1038/nature14677 [3] 吴中伟. 高性能混凝土: 绿色混凝土[J]. 混凝土与水泥制品, 2000(1): 3-6. https://www.cnki.com.cn/Article/CJFDTOTAL-HNTW200001000.htmWu Zhongwei. High performance concrete-green concrete[J]. China Concrete and Cement Products, 2000(1): 3-6. https://www.cnki.com.cn/Article/CJFDTOTAL-HNTW200001000.htm [4] Olivier J, Peters J. Trends in global CO2 and total greenhouse gas emissions[R]. PPBL Netherlands Environmental Assessment Agency, 2019. [5] Celik K, Meral C, Petek Gursel A, et al. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended Portland cements containing fly ash and limestone powder[J]. Cement and Concrete Composites, 2015, 56: 59-72. doi: 10.1016/j.cemconcomp.2014.11.003 [6] Hay R, Ostertag C P. Life cycle assessment (LCA)of double-skin facade (DSF)system with fiber-reinforced concrete for sustainable and energy-efficient buildings in the tropics[J]. Building and Environment, 2018, 142: 327-341. doi: 10.1016/j.buildenv.2018.06.024 [7] Lothenbach B, Scrivener K, Hooton R D. Supplementary cementitious materials[J]. Cement and Concrete Research, 2011, 41(12): 1244-1256. doi: 10.1016/j.cemconres.2010.12.001 [8] 谭永山, 余红发, 李颖, 等. 利用盐湖提锂副产含硼氧化镁制备粉煤灰磷酸钾镁水泥[J]. 硅酸盐学报, 2014, 42(11): 1362-1369. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201411003.htmTan Yongshan, Yu Hongfa, Li Ying, et al. Preparation of fly ash magnesium potassium phosphate cement using byproduct magnesium oxide containing boron from salt lakes[J]. Journal of the Chinese Ceramic Society, 2014, 42(11): 1362-1369. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201411003.htm [9] 黄青. 氯氧镁水泥的抗盐卤腐蚀性能研究[D]. 西宁: 中国科学院大学中国科学院青海盐湖研究所, 2020. [10] Unluer C, Al-Tabbaa A. Impact of hydrated magnesium carbonate additives on the carbonation of reactive MgO cements[J]. Cement and Concrete Research, 2013, 54: 87-97. doi: 10.1016/j.cemconres.2013.08.009 [11] Unluer C, Al-Tabbaa A. The role of brucite, ground granulated blast furnace slag, and magnesium silicates in the carbonation and performance of MgO cements[J]. Construction and Building Materials, 2015, 94: 629-643. doi: 10.1016/j.conbuildmat.2015.07.105 [12] Eubank W R. Calcination studies of magnesium oxides[J]. Journal of the American Ceramic Society, 1951, 34(8): 225-229. doi: 10.1111/j.1151-2916.1951.tb11644.x [13] 林宗寿. 胶凝材料学[M]. 武汉: 武汉理工大学出版社, 2014. [14] 文静, 余红发, 吴成友, 等. 氯氧镁水泥水化历程的影响因素及水化动力学[J]. 硅酸盐学报, 2013, 41(5): 588-596. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201305005.htmWen Jing, Yu Hongfa, Wu Chengyou, et al. Hydration kinetic and influencing parameters in hydration process of magnesium oxychloride cement[J]. Journal of the Chinese Ceramic Society, 2013, 41(5): 588-596. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201305005.htm [15] 朱效甲, 朱玉杰, 朱效涛, 等. 国内硫氧镁水泥外加剂的研究现状及展望[J]. 建材技术与应用, 2018(5): 1-4, 10. doi: 10.13923/j.cnki.cn14-1291/tu.2018.05.001Zhu Xiaojia, Zhu YuJie, Zhu Xiaotao, et al. Current research status and prospect of Additives to magnesium oxychloride cement in China[J]. Research & Application of Building Materials, 2018(5): 1-4, 10. doi: 10.13923/j.cnki.cn14-1291/tu.2018.05.001 [16] 袁大伟. 利用硼泥制备磷酸镁水泥[D]. 大连: 大连理工大学, 2008. [17] Ribeiro D V, Morelli M R. Influence of the addition of grinding dust to a magnesium phosphate cement matrix[J]. Construction and Building Materials, 2009, 23(9): 3094-3102. doi: 10.1016/j.conbuildmat.2009.03.013 [18] 杨建明, 钱春香, 张青行, 等. 原料粒度对磷酸镁水泥水化硬化特性的影响[J]. 东南大学学报: 自然科学版, 2010, 40(2): 373-379. https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201002031.htmYang Jianming, Qian Chunxiang, Zhang Qinghang, et al. Effects of particle size of starting materials on hydration and hardening process of magnesia-phosphate cement[J]. Journal of Southeast University: Natural Science Edition, 2010, 40(2): 373-379. https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201002031.htm [19] 杨建明, 钱春香, 焦宝祥, 等. Na2HPO4·12H2O对磷酸镁水泥水化硬化特性的影响[J]. 建筑材料学报, 2011, 14(3): 299-304. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX201103006.htmYang Jianming, Qian Chunxiang, Jiao Baoxiang, et al. Effect of Na2HPO4·12H2O on hydration and hardening properties of potassium and magnesium phosphate cement paste[J]. Journal of Building Materials, 2011, 14(3): 299-304. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX201103006.htm [20] 焦宝祥, 周启兆, 阎晓波, 等. MgO-(NH4)2HPO4-K2HPO4-H2O新型磷酸镁水泥[J]. 建筑材料学报, 2012, 15(1): 131-134. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX201201027.htmJiao Baoxiang, Zhou Qizhao, Yan Xiaobo, et al. New magnesia-phosphate cement based on MgO-(NH4)2HPO4-K2HPO4-H2O system[J]. Journal of Building Materials, 2012, 15(1): 131-134. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX201201027.htm [21] Gui L, Hui X, Chao Y, et al. Preparation of high purity light magnesium oxide by magnesium waste from lithium extraction process of salt lake[J]. Inorganic Chemicals Industry, 2015, 47(4): 73-76. [22] Chau C K, Li Z J. Microstructures of magnesium oxychloride[J]. Materials and Structures, 2008, 41(5): 853-862. doi: 10.1617/s11527-007-9289-y [23] Liu Z Z, Wang S, Huang J, et al. Experimental investigation on the properties and microstructure of magnesium oxychloride cement prepared with caustic magnesite and dolomite[J]. Construction and Building Materials, 2015, 85: 247-255. doi: 10.1016/j.conbuildmat.2015.01.056 [24] Sglavo V M, De Genua F, Conci A, et al. Influence of curing temperature on the evolution of magnesium oxychloride cement[J]. Journal of Materials Science, 2011, 46(20): 6726-6733. doi: 10.1007/s10853-011-5628-z [25] Tan Y N, Liu Y, Grover L. Effect of phosphoric acid on the properties of magnesium oxychloride cement as a biomaterial[J]. Cement and Concrete Research, 2014, 56: 69-74. doi: 10.1016/j.cemconres.2013.11.001 [26] 葛绍进, 张旭, 王红宁, 等. 高活性MgO对低温氯氧镁水泥物相及性能的影响[J]. 硅酸盐学报, 2019, 47(7): 865-873. doi: 10.14062/j.issn.0454-5648.2019.07.02Ge Shaojin, Zhang Xu, Wang Hongning, et al. Effect of high activity MgO on phase and properties of magnesium oxychloride cement at low temperatures[J]. Journal of the Chinese Ceramic Society, 2019, 47(7): 865-873. doi: 10.14062/j.issn.0454-5648.2019.07.02 [27] Zhang X, Ge S J, Wang H N, et al. Effect of 5-phase seed crystal on the mechanical properties and microstructure of magnesium oxychloride cement[J]. Construction and Building Materials, 2017, 150: 409-417. doi: 10.1016/j.conbuildmat.2017.05.211 [28] Sugimoto K, Dinnebier R E, Schlecht T. Structure determination of Mg3(OH)5Cl·4H2O (F5 phase)from laboratory powder diffraction data and its impact on the analysis of problematic magnesia floors[J]. Acta Crystallographica Section B Structural Science, 2007, 63(6): 805-811. doi: 10.1107/S0108768107046654 [29] Bilinski H, Matković B, Mažuranić C, et al. The formation of magnesium oxychloride phases in the systems MgO-MgCl2-H2O and NaOH-MgCl2-H2O[J]. Journal of the American Cermaic Society, 2006, 67(4): 266-269. doi: 10.1111/j.1151-2916.1984.tb18844.x [30] Ved E I, Zharov E F, Phong H V. Mechanism of magnesium oxychloride formation during the hardening of magnesium oxychloride cement[J]. Zh Prikl Khim, 1976, 49(10): 2154-2158. [31] 余红发. 氯氧镁水泥及其应用[M]. 北京: 中国建材工业出版社, 1993. [32] Deng D H, Zhang C M. The formation mechanism of the hydrate phases in magnesium oxychloride cement[J]. Cement and Concrete Research, 1999, 29(9): 1365-1371. doi: 10.1016/S0008-8846(98)00247-6 [33] Wu J Y, Guan B W, Chen H X, et al. Effects of polycarboxylate superplasticiser on the early hydration properties of magnesium oxychloride cement[J]. Construction and Building Materials, 2020, 259: 119862. doi: 10.1016/j.conbuildmat.2020.119862 [34] 陈常明. 新型镁水泥基复合材料的组成与性能研究[D]. 武汉: 武汉理工大学, 2010. [35] Yin L. Reseach development on hydration product, phase transformation and water resistance evaluation method of magnesium oxychloride cement[J]. Journal of the Chinese Ceramic Society, 2013, 41(11): 1465-1473. [36] 郑卫新. 氯氧镁水泥泡沫混凝土设计与应用基础研究[D]. 西宁: 中国科学院青海盐湖研究所, 2019. [37] 蔡相连, 王昊宇, 王敏, 等. 聚羧酸减水剂增强氯氧镁水泥性能研究[J]. 公路, 2023, 68(4): 325-329. https://www.cnki.com.cn/Article/CJFDTOTAL-GLGL202304054.htmCai Xianglian, Wang Haoyu, Wang Min, et al. Study on properties of magnesium oxychloride cement reinforced by polycarboxylic acid water reducer[J]. Highway, 2023, 68(4): 325-329. https://www.cnki.com.cn/Article/CJFDTOTAL-GLGL202304054.htm [38] Cole W F, Demediuk T. X-ray, thermal, and dehydration studies on magnesium oxychlorides[J]. Australian Journal of Chemistry, 1955, 8(2): 234-251. doi: 10.1071/CH9550234 [39] 刘江武. 碱式硫酸镁水泥耐水性研究[D]. 哈尔滨: 哈尔滨理工大学, 2017. [40] Mostafa N Y, Brown P W. Heat of hydration of high reactive pozzolans in blended cements: Isothermal conduction calorimetry[J]. Thermochimica Acta, 2005, 435(2): 162-167. doi: 10.1016/j.tca.2005.05.014 [41] Urwongse L, Sorrell C A. Phase relations in magnesium oxysulfate cements[J]. Journal of the American Ceramic Society, 1980, 63(9/10): 523-526. [42] 房卉. 铝酸盐水泥对硫氧镁水泥性能的影响[D]. 鞍山: 辽宁科技大学, 2021. [43] Langan B W and K, Ward M A. Ward. Effect of silica fume and fly ash on heat of hydration of Portland cement[J]. Cement and Concrete Research, 2002, 32(7): 1045-1051. doi: 10.1016/S0008-8846(02)00742-1 [44] 丁铸, 洪鑫, 朱继翔, 等. 碱激发赤泥-矿渣地聚合物水泥的研究[J]. 电子显微学报, 2018, 37(2): 145-153. https://www.cnki.com.cn/Article/CJFDTOTAL-DZXV201802008.htmDing Zhu, Hong Xin, Zhu Jixiang, et al. Alkali-activated red mud-slag cementitious materials[J]. Journal of Chinese Electron Microsopy Society, 2018, 37(2): 145-153. https://www.cnki.com.cn/Article/CJFDTOTAL-DZXV201802008.htm [45] Wu C Y, Chen W H, Zhang H F, et al., The hydration mechanism and performance of Modified magnesium oxysulfate cement by tartaric acid[J]. Construction and Building Materials, 2017, 144: 516-524. doi: 10.1016/j.conbuildmat.2017.03.222 [46] Wang A J, Fan X J, Li J M, et al. Curing behavior and structure of magnesium phosphate chemically bonded ceramics with different MgO to KH2PO4ratios[J]. International Journal of Applied Ceramic Technology, 2015, 12(6): 1124-1130. doi: 10.1111/ijac.12329 [47] Le Rouzic M, Chaussadent T, Platret G, et al. Mechanisms of k-struvite formation in magnesium phosphate cements[J]. Cement and Concrete Research, 2017, 91: 117-122. doi: 10.1016/j.cemconres.2016.11.008 [48] Xu B, Ma H, Li Z. Influence of magnesia-to-phosphate molar ratio on microstructures, mechanical properties and thermal conductivity of magnesium potassium phosphate cement paste with large water-to-solid ratio[J]. Cement & Concrete Research, 2015, 68: 1-9. [49] 闫浩康, 王硕, 时绪智, 等. 不同矿物掺合料对改性硫氧镁水泥性能影响的研究[J]. 硅酸盐通报, 2022, 41(1): 27-32. doi: 10.16552/j.cnki.issn1001-1625.2022.01.002Yan Haokang, Wang Shuo, Shi Xuzhi, et al. Effects of different mineral admixtures on properties of modified magnesium oxysulfate cement[J]. Bulletin of the Chinese Ceramic Society, 2022, 41(1): 27-32. doi: 10.16552/j.cnki.issn1001-1625.2022.01.002 [50] 贾兴文, 连磊, 田昊, 等. 超高性能磷酸镁水泥混凝土的制备和力学性能研究[J]. 功能材料, 2022, 53(6): 6019-6024. https://www.cnki.com.cn/Article/CJFDTOTAL-GNCL202206004.htmJia Xingwen, Lian Lei, Tian Hao, et al. The preparation and mechanical properties of ultra high performance magnesium phosphate cement concrete[J]. Journal of Functional Materials, 2022, 53(6): 6019-6024. https://www.cnki.com.cn/Article/CJFDTOTAL-GNCL202206004.htm [51] 刘进, 呙润华, 张增起. 磷酸镁水泥性能的研究进展[J]. 材料导报, 2021, 35(23): 23068-23075. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202123008.htmLiu Jin, Guo Runhua, Zhang Zengqi. Research progress of properties of magnesium phosphate cement[J]. Materials Reports, 2021, 35(23): 23068-23075. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202123008.htm [52] 常成功, 文静, 董金美, 等. 碳化作用对镁质胶凝材料微观结构演变过程的影响[J]. 无机盐工业, 2022, 54(6): 61-65. doi: 10.19964/j.issn.1006-4990.2021-0546Chang Chenggong, Wen Jing, Dong Jinmei, et al. Effect of carbonization on evolution process of microstructure of magnesium oxychloride cement[J]. Inorganic Chemicals Industry, 2022, 54(6): 61-65. doi: 10.19964/j.issn.1006-4990.2021-0546 [53] Power I M, Dipple G M, Francis P S. Assessing the carbon sequestration potential of magnesium oxychloride cement building materials[J]. Cement and Concrete Composites, 2017, 78: 97-107. doi: 10.1016/j.cemconcomp.2017.01.003 [54] Yang J M, Lu J W, Wu Q S, et al. Influence of steel slag powders on the properties of MKPC paste[J]. Construction and Building Materials, 2018, 159: 137-146. doi: 10.1016/j.conbuildmat.2017.10.081 [55] Gochez R, Vreeland T, Wambaugh J, et al. Conversion of magnesium oxychloride to chlorartinite and resulting increased water resistance[J]. Materials Letters, 2017, 207: 1-3. doi: 10.1016/j.matlet.2017.06.124 [56] 郑利娜, 余红发, 董金美, 等. 碳化对玻璃纤维增强氯氧镁水泥性能的影响规律及其机理[J]. 材料导报, 2013, 27(12): 141-143, 148. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201312034.htmZheng Lina Z, Yu Hongfa, Dong Jinmei, et al. Influence of carbonation on performance of glass fiber reinforced magnesium oxychloride cement[J]. Materials Review, 2013, 27(12): 141-143, 148. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201312034.htm [57] 曹明莉, 唐尔卓, 王立久. Cl-离子捕捉剂对氯氧镁水泥改性实验研究[J]. 水泥技术, 2010(6): 40-45. https://www.cnki.com.cn/Article/CJFDTOTAL-SNJS201006009.htmCao Mingli, Tang Erzhuo, Wang Lijiu. Experimental research on improving MOC by Cl- ion catcher[J]. Cement Technology, 2010(6): 40-45. https://www.cnki.com.cn/Article/CJFDTOTAL-SNJS201006009.htm [58] 陈益民, 张文生, 张洪滔, 等. 氯氧镁水泥水化研究[C]// 中国硅酸盐学会2003年学术年会水泥基材料论文集(上册). 北京, 2003: 542-546. [59] 单继元. 硫氧镁胶凝材料的改性及复合技术研究[D]. 石家庄: 河北科技大学, 2021. [60] 宋绍辉, 李亚伟, 廖宁, 等. 基于水氯镁石合成水合硅酸镁及其在镁质浇注料的应用[J]. 硅酸盐通报, 2023, 42(2): 751-760. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202302039.htmSong Shaohui, Li Yawei, Liao Ning, et al. Synthesis of magnesium silicate hydrate based on bischofite and its application in magnesia castables[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(2): 751-760. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202302039.htm [61] 宋明礼, 孙庆国, 肖学英, 等. 外加剂对改善镁水泥抗水性能的研究[J]. 盐湖研究, 1993, 1(4): 71-74. https://www.cnki.com.cn/Article/CJFDTOTAL-YHYJ199304009.htmSong Mingli, Sun Qingguo, Xiao Xueying, et al. Study of addition on improving the water-resistant feature of magnesium cement[J]. Journal of Salt Lake Research, 1993, 1(4): 71-74. https://www.cnki.com.cn/Article/CJFDTOTAL-YHYJ199304009.htm [62] 吴大龙, 刘庆伟, 于浩, 等. 不同配合比氯氧镁水泥在卤水中强度发展规律试验研究[J]. 混凝土, 2014(4): 24-27. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201404009.htmWu Dalong, Liu Qingwei, Yu Hao, et al. Experimental research of strength development regularity of different ratiosof magnesium oxychloride cement in brine[J]. Concrete, 2014(4): 24-27. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201404009.htm [63] Runcevski T, Wu C Y, Yu H F, et al. Structural characterization of a new magnesium oxysulfate hydrate cement phase and its surface reactions with atmospheric carbon dioxide[J]. Journal of the American Ceramic Society, 2013, 96(11): 3609-3616. doi: 10.1111/jace.12556 [64] Ba M F, Xue T, He Z M, et al. Carbonation of magnesium oxysulfate cement and its influence on mechanical performance[J]. Construction and Building Materials, 2019, 223: 1030-1037. doi: 10.1016/j.conbuildmat.2019.07.341 [65] 李振国. 外掺料对硫氧镁水泥组织及性能的影响[D]. 哈尔滨: 哈尔滨理工大学, 2017. [66] 吴成友. 碱式硫酸镁水泥的基本理论及其在土木工程中的应用技术研究[D]. 北京: 中国科学院大学, 2014. [67] 张巨松, 董孟肖. 复合改性硫氧镁水泥的性能研究[J]. 沈阳建筑大学学报: 自然科学版, 2019, 35(2): 324-330. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJZ201902017.htmZhang Jusong, Dong Mengxiao. The properties of compound modified magnesium oxysulfate cement[J]. Journal of Shenyang Jianzhu University: Natural Science, 2019, 35(2): 324-330. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJZ201902017.htm [68] 董孟肖. 硫氧镁水泥的改性及其应用研究[D]. 沈阳: 沈阳建筑大学, 2018. [69] 朱效甲, 朱倩倩, 朱玉杰, 等. 不同测试方法对氯氧镁水泥制品氯离子含量测试结果的影响[J]. 江苏建材, 2019(5): 39-43. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJW201905014.htmZhu Xiaojia, Zhu Qianqian, Zhu Yujie, et al. The influence of different test methods on chloride ion content test results of magnesium oxychloride cement products[J], Jiangsu Building Materials, 2019(5): 39-43. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJW201905014.htm [70] 安生霞, 肖学英, 李颖, 等. 硫、氯氧镁混合胶凝体系凝结硬化性能及微观结构[J]. 硅酸盐通报, 2017, 36(8): 2607-2613, 2624. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201708016.htmAn Shengxia, Xiao Xueying, Li Ying, et al. Setting, hardening characteristics and microstructure of magnesium oxysulfate and magnesium oxychloride mixed cementious system[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(8): 2607-2613, 2624. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201708016.htm [71] Zhang N, Yu H F, Wang N, et al. Effects of low-and high-calcium fly ash on the water resistance of magnesium oxysulfate cement[J]. Construction and Building Materials, 2019, 215: 162-170. [72] 崔宝栋, 关岩, 毕万利, 等. 不同矿物掺料对硫氧镁水泥耐热性能的影响[J]. 硅酸盐通报, 2020, 39(2): 428-434. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202002014.htmCui Baodong, Guan Yan, Bi Wanli, et al. Effect of different mineral admixtures on heat resistance of magnesium oxysulfate cement[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(2): 428-434. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202002014.htm [73] Tan Y, Wu C, Yu H, et al. Review of reactive magnesia-based cementitious materials: current developments and potential applicability[J]. Journal of Building Engineering, 2021, 40: 102342. [74] Ba M F, Gao Q, Ma Y L, et al. Improved hydration and properties of magnesium oxysulfate (MOS)cement using sodium silicate as an additive[J]. Construction and Building Materials, 2021, 267: 120988. [75] 付希尧. 改性剂和掺合料对硫氧镁水泥基材料性能影响研究进展[J]. 四川建材, 2019, 45(9): 10-12. https://www.cnki.com.cn/Article/CJFDTOTAL-SCJZ201909006.htmFu Xiyao. Research progress on the influence of modifiers and admixtures on the properties of magnesium oxysulfate cement-based materials[J]. Sichuan Building Materials, 2019, 45(9): 10-12. https://www.cnki.com.cn/Article/CJFDTOTAL-SCJZ201909006.htm [76] 巴明芳, 许浩锋, 朱杰兆, 等. 活性混合材对改性硫氧镁胶凝材料性能的影响[J]. 建筑材料学报, 2020, 23(4): 763-770. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX202004005.htmBa Mingfang, Xu Haofeng, Zhu Jiezhao, et al. Effects of active admixtures on properties of modified magnesium oxysulfate cemented materials[J]. Journal of Building Materials, 2020, 23(4): 763-770. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX202004005.htm [77] 黄泓萍. 碱式硫酸镁水泥的配料规律与基本性能[D]. 南京: 南京航空航天大学, 2016. [78] 杨正宏, 刘思佳, 吴凯, 等. 纤维增强磷酸镁水泥基复合材料研究进展[J]. 材料导报, 2023, 37(1): 118-124. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202301015.htmYang Zhenghong, Liu Sijia, Wu Kai, et al. Research progress on fiber reinforced magnesium phosphate cement composites[J]. Materials Reports, 2023, 37(1): 118-124. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202301015.htm [79] Qiao F, Chau C K, Li Z J. Property evaluation of magnesium phosphate cement mortar as patch repair material[J]. Construction and Building Materials, 2010, 24(5): 695-700. [80] Le Rouzic M, Chaussadent T, Stefan L, et al. On the influence of Mg/P ratio on the properties and durability of magnesium potassium phosphate cement pastes[J]. Cement and Concrete Research, 2017, 96: 27-41. [81] 邓恺, 黎红兵, 李响, 等. 不同养护条件下钢渣与粉煤灰改性磷酸镁水泥的性能研究[J]. 材料导报, 2019, 33(S1): 264-268. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2019S1056.htmDeng Kai, Li Hongbin, Li Xiang, et al. Study on the performance of steel slag and fly ash modified magnesium phosphate cements under different curing condition[J]. Materials Reports, 2019, 33(S1): 264-268. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2019S1056.htm [82] 赵江涛, 李相国, 张琰, 等. 粉煤灰对磷酸镁水泥的影响[J]. 硅酸盐通报, 2018, 37(2): 695-700. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201802052.htmZhao Jiangtao, Li Xiangguo, Zhang Yan, et al. Effects of fly ash on magnesium phosphate cement[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(2): 695-700. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201802052.htm [83] 田海涛, 吴佳育, 关博文. 粉煤灰对磷酸镁水泥早期性能的影响[J]. 硅酸盐通报, 2019, 38(6): 1812-1817. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201906029.htmTian Haitao, Wu Jiayu, Guan Bowen. Effect of fly ash on rheological properties of magnesium phosphate cement[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(6): 1812-1817. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201906029.htm [84] 吴庆, 许奇, 杨建明, 等. 铝硅质矿物掺合料对磷酸钾镁水泥砂浆物理力学性能的影响[J]. 新型建筑材料, 2019, 46(11): 122-126. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201911032.htmWu Qing, Xu Qi, Yang Jianming, et al. Effect of aluminous silica mineral admixture on physical and mechanical properties of potassium magnesium phosphate cement mortar[J]. New Building Materials, 2019, 46(11): 122-126. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201911032.htm [85] 陈兵, 吴震, 吴雪萍. 磷酸镁水泥改性试验研究[J]. 武汉理工大学学报, 2011, 33(4): 29-34. https://www.cnki.com.cn/Article/CJFDTOTAL-WHGY201104008.htmChen Bing, Wu Zhen, Wu Xueping. Experimental research on the properties of modified MPC[J]. Journal of Wuhan University of Technology, 2011, 33(4): 29-34. https://www.cnki.com.cn/Article/CJFDTOTAL-WHGY201104008.htm [86] 赵春洋, 范文强, 李春庆, 等. 碱式硫酸镁晶须对氯氧镁水泥性能的影响[J]. 硅酸盐通报, 2020, 39(2): 435-439, 458. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202002015.htmZhao Chunyang, Fan Wenqiang, Li Chunqing, et al. Effect of magnesium hydroxide sulfate hydrate whiskers on the properties of magnesium oxychloride cement[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(2): 435-439, 458. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202002015.htm [87] 纪荣健, 杨建明, 吴庆, 等. 水玻璃对大流动度的磷酸铵镁水泥浆体性能的影响[J]. 硅酸盐通报, 2020, 39(1): 28-33. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202001004.htmJi Rongjian, Yang Jianming, Wu Qing, et al. Effect of water glass on properties of high flowing magnesium ammonium phosphate cement paste[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(1): 28-33. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202001004.htm [88] 孙婧, 王宏, 兰建伟, 等. 添加剂对磷酸镁水泥抗水性能影响的机理分析[J]. 河北建筑工程学院学报, 2019, 37(4): 20-25. https://www.cnki.com.cn/Article/CJFDTOTAL-HBJZ201904004.htmSun Jing, Wang Hong, Lan Jianwei, et al. Analysis of the effect of additives on water resistance of magnesium phosphate cement[J]. Journal of Hebei Institute of Architecture and Civil Engineering, 2019, 37(4): 20-25. https://www.cnki.com.cn/Article/CJFDTOTAL-HBJZ201904004.htm -

下载:

下载: