Research on the influence of light intensity on digital image correlation measurement accuracy in the testing of concrete

-

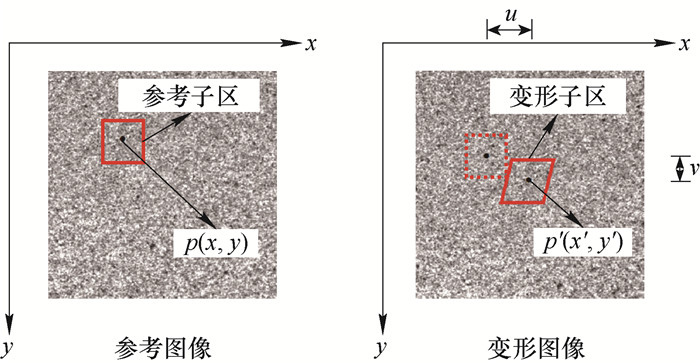

摘要: 在复杂光照条件下采用数字图像相关技术(DIC)测量混凝土结构表面应变场时,光强变化会引起图像的退相关效应。针对此问题,基于传统2D-DIC测量系统,探究了光强变化对DIC测量精度与计算效率的影响规律。试验结果表明:平均灰度190为最优光强;以最优光强下的图片作为参考图像,光强增大时应变误差呈指数增长,光强减小时应变误差呈线性增长;计算时间与计算点匹配率对光强的小范围波动不敏感,但光强的剧烈变化会导致计算时间增加1~3倍以及25 % 的计算点匹配失败。结合图像质量评估指标,验证了实验结果的准确性。为了获得高质量的图像,本文建立了绿光带通滤波成像系统,该系统在外界环境光剧烈变化条件下依然能够保持图像的亮度与对比度基本不变,应变误差与计算效率均接近于最优光强。相对于传统2D-DIC测量系统,绿光带通滤波成像系统可较好地应用到室外环境测量。

-

关键词:

- 数字图像相关技术 /

- 混凝土表面应变场 /

- 光强 /

- 图像质量 /

- 绿光带通滤波成像系统

Abstract: When the surface strain field of concrete structure is measured by digital image correlation(DIC)technology under complex light conditions, the decorrelation effect of the pattern will be caused by the variation in light intensity. For this problem, the optimal light intensity suitable for DIC calculating and analyzing is studied, and the influence of light intensity variation on the measurement accuracy and calculation efficiency of DIC is explored by the traditional 2D-DIC measurement system. The experimental result shows that the average gray level of 190 is the optimal light intensity. The picture is used as the reference image at the optimal light intensity. The strain error increases exponentially when the light intensity increases, and the strain error increases linearly when the light intensity decreases. The computation time and the matching rate of calculation points are insensitive to the slight range fluctuation of light intensity, while the computation time of DIC will increase 1 to 3 times, and about 25 % of calculation points will match failed because of the extreme variation of light intensity. The accuracy of experimental results is verified by Combining them with the image quality assessment index. In order to get high-quality images, the green band-pass filter imaging system is established in this paper. It can stabilize the image's brightness and contrast when the external light varies seriously. The strain error and calculation efficiency are all close to the optimal light intensity when external ambient light changes seriously. Compared with the traditional 2D-DIC measurement system, The green band-pass filter imaging system can be better applied to measure in the outdoor environment. -

表 1 光强变化时传统2D-DIC测量系统与绿光带通滤波成像系统应变场测量误差

Table 1. Comparison of strain measuring error between traditional 2D-DIC measurement system and green band-pass filter imaging system when light intensity changes

应变测量误差 低照度 最优光强 高照度 传统2D-DIC测量系统 绿光带通滤波成像系统 传统2D-DIC测量系统 绿光带通滤波成像系统 传统2D-DIC测量系统 绿光带通滤波成像系统 x方向应变测量误差/ 10-6 66 63 25 45 58 993 79 y方向应变测量误差/ 10-6 56 44 22 21 57 894 68 xy方向应变测量误差/ 10-6 44 44 19 21 23 583 49 表 2 光强变化时传统2D-DIC测量系统与绿光带通滤波成像系统所采集的图像质量

Table 2. Comparison of the quality of the pattern collected by traditional 2D-DIC measurement system and the green band-pass filter imaging system when light intensity changes

图像质量 低照度 最优光强 高照度 传统2D-DIC测量系统 绿光带通滤波成像系统 传统2D-DIC测量系统 绿光带通滤波成像系统 传统2D-DIC测量系统 绿光带通滤波成像系统 平均灰度 20.89 173.59 190.41 192.77 254.78 208.59 平均灰度梯度 3.21 39.48 27.76 39.85 0.3 37.42 表 3 光强变化时传统2D-DIC测量系统与绿光带通滤波成像系统的计算效率

Table 3. Comparison of the efficiency of calculation between traditional 2D-DIC measurement system and green band-pass filter imaging system when light intensity changes

计算效率 低照度 最优光强 高照度 传统2D-DIC测量系统 绿光带通滤波成像系统 传统2D-DIC测量系统 绿光带通滤波成像系统 传统2D-DIC测量系统 绿光带通滤波成像系统 计算时间/ s 0.297 0.125 0.124 0.125 0.488 0.126 计算点匹配率/% 100 100 100 100 75 100 -

[1] 张德海, 郭照灿, 何文斌, 等. 用于Q235低碳钢的数字图像相关法应变检测[J]. 锻压技术, 2022, 47(3): 182-190. https://www.cnki.com.cn/Article/CJFDTOTAL-DYJE202203031.htmZhang Dehai, Guo Zhaocan, He Wenbin, et al. Strain detection by digital image correlation method on Q235 low carbon steel[J]. Forging & Stamping Technology, 2022, 47(3): 182-190. https://www.cnki.com.cn/Article/CJFDTOTAL-DYJE202203031.htm [2] Pan B, Qian K M, Xie H M, et al. Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review[J]. Measurement Science and Technology, 2009, 20(6): 062001. doi: 10.1088/0957-0233/20/6/062001 [3] 金观昌, 孟利波, 陈俊达, 等. 数字散斑相关技术进展及应用[J]. 实验力学, 2006, 21(6): 689-702. https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX200606002.htmJin Guanchang, Meng Libo, Chen Junda, et al. The progress and application of digital speckle correlation method[J]. Journal of Experimental Mechanics, 2006, 21(6): 689-702. https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX200606002.htm [4] Yamaguchi I. Speckle displacement and decorrelation in the diffraction and image fields for small object deformation[J]. Optica Acta: International Journal of Optics, 1981, 28(10): 1359-1376. doi: 10.1080/713820454 [5] Yamaguchi I. A laser-speckle strain gauge[J]. Journal of Physics E: Scientific Instruments, 1981, 14(11): 1270-1273. doi: 10.1088/0022-3735/14/11/012 [6] Peters W H, Ranson W F. Digital imaging techniques in experimental stress analysis[J]. Optical Engineering, 1982, 21(3): 427-431. [7] 吴庆, 倪源, 孙林柱, 等. 基于VIC-3D技术的高强混凝土单轴受压试验研究[J]. 混凝土, 2014(11): 19-23. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201411007.htmWu Qing, Ni Yuan, Sun Linzhu, et al. Experimental study on high-strength concrete under uniaxial compression based on VIC-3D technology[J]. Concrete, 2014(11): 19-23. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201411007.htm [8] 童晶, 金贤玉, 田野, 等. 基于DIC技术的锈蚀钢筋混凝土表面开裂[J]. 浙江大学学报: 工学版, 2015, 49(2): 193-199, 217. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC201502001.htmTong Jing, Jin Xianyu, Tian Ye, et al. Study on surface cracking of corroded reinforced concrete based on DIC method[J]. Journal of Zhejiang University: Engineering Science, 2015, 49(2): 193-199, 217. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC201502001.htm [9] 赵燕茹, 张杰, 宋博, 等. 基于DIC方法的高温后混凝土应变局部化研究[J]. 混凝土, 2022(4): 37-43. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF202204008.htmZhao Yanru, Zhang Jie, Song Bo, et al. Research on strain localization of concrete after high temperature based on DIC method[J]. Concrete, 2022(4): 37-43. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF202204008.htm [10] Ma S P, Jin G C. New correlation coefficients designed for digital speckle correlation method(DSCM)[C]// Proc SPIE 5058, Optical Technology and Image Processing for Fluids and Solids Diagnostics 2002, 2003, 5058: 25-33. [11] 潘兵, 续伯钦, 谢惠民, 等. 面内位移测量的基于梯度的数字图像相关方法[J]. 光学技术, 2005, 31(5): 643-647. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJS200505000.htmPan Bing, Xu Boqin, Xie Huimin, et al. In-plane displacement measurement by gradient-based digital image correlation[J]. Optical Technique, 2005, 31(5): 643-647. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJS200505000.htm [12] Hua T, Xie H M, Wang S, et al. Evaluation of the quality of a speckle pattern in the digital image correlation method by mean subset fluctuation[J]. Optics & Laser Technology, 2011, 43(1): 9-13. [13] Grant B B, Stone H J, Withers P J, et al. High-temperature strain field measurement using digital image correlation[J]. The Journal of Strain Analysis for Engineering Design, 2009, 44(4): 263-271. [14] Su Z L, Lu L, Dong S, et al. Auto-calibration and real-time external parameter correction for stereo digital image correlation[J]. Optics and Lasers in Engineering, 2019, 121: 46-53. [15] Pappa R S, Giersch L R, Quagliaroli J M. Photogrammetry of a 5m inflatable space antenna with consumer-grade digital cameras[J]. Experimental Techniques, 2001, 25(4): 21-29. [16] Zhang H, Wang Y H, Chen L, et al. High temperature deformation measurement based on ultraviolet DIC[C]// SPIE Proceedings, International Conference on Experimental Mechanics 2014, Singapore. Singapore: SPIE, 2015. [17] Bao S Y, Wang Y H, Liu L, et al. An error elimination method for high-temperature digital image correlation using color speckle and camera[J]. Optics and Lasers in Engineering, 2019, 116: 47-54. [18] Tong W. An evaluation of digital image correlation criteria for strain mapping applications[J]. Strain, 2005, 41(4): 167-175. [19] 王冬梅, 方如华, 秦玉文. 数字图像相关测量的误差分析及其改进措施[J]. 实验力学, 1998, 13(3): 416-422. https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX803.021.htmWang Dongmei, Fang Ruhua, Qin Yuwen. Measuring errors analysis and improvement of digital image correlation method measurement system[J]. Journal of Experimental Mechanics, 1998, 13(3): 416-422. https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX803.021.htm [20] 潘兵, 吴大方, 夏勇. 数字图像相关方法中散斑图的质量评价研究[J]. 实验力学, 2010, 25(2): 120-129. https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX201002001.htmPan Bing, Wu Dafang, Xia Yong. Study of speckle pattern quality assessment used in digital image correlation[J]. Journal of Experimental Mechanics, 2010, 25(2): 120-129. https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX201002001.htm [21] Pan B, Wu D F, Yu L P. Optimization of a three-dimensional digital image correlation system for deformation measurements in extreme environments[J]. Applied Optics, 2012, 51(19): 4409. [22] 钱月红. EMCCD光电性能参数测试方法研究[D]. 南京: 南京理工大学, 2015. -

下载:

下载: