Numerical simulation study of rock breaking mechanism by high voltage electric pulse

-

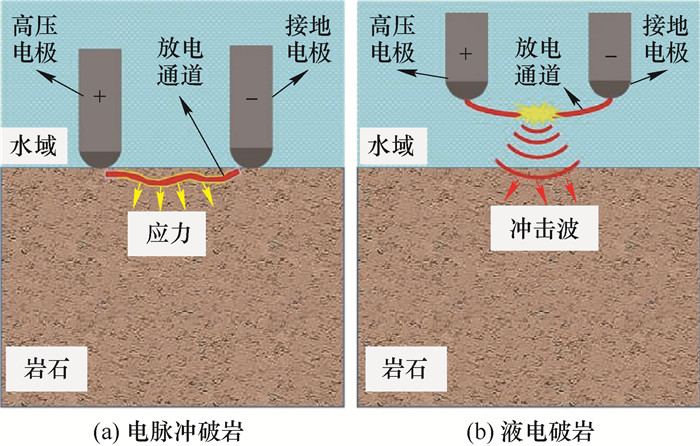

摘要: 高压电脉冲钻井技术目前已成为一种新型高效的岩石破碎方法,同时也是目前钻井提速领域的研究热点。为了推动高压电脉冲的破岩机理研究,建立了单对电极破碎红砂岩的多物理场耦合电击穿二维数值模型,通过电流场、电击穿场和电路场的耦合再现均质红砂岩中等离子体通道的产生,分析了电极倾角、电压、电极间距对岩石电击穿(岩石内部等离子体通道的形成)的影响规律。研究表明:等离子体通道由靠近放电电极顶端局部区域开始萌生,并朝着岩石局部介电强度薄弱处发展;随着加载脉冲电压值的增大,电击穿发生时刻逐步降低,岩石模型的等效失效体积逐渐增大;在保证岩石能被电击穿的前提下,增大电极间距能提高高压电脉冲的破岩效率;放电电极的电极倾角逐步增大的过程中,岩石等效失效体积出现明显的波动,其极值多数出现在电极倾角35°~55°的范围之内。为了进一步推动高压电脉冲破岩的工业化应用,在二维模型基础上构建了红砂岩的多物理场耦合动态电击穿三维数值模型,再现了电极钻头破岩过程中岩石内部破碎坑的状貌;与此同时,选用自主设计的同轴型电脉冲钻头开展了电击穿室内实验,电击穿室内实验结果与仿真实验结果相互印证。Abstract: High-voltage electric pulse(HVEP)drilling has become a new and efficient rock breaking method, which is also the research focus in the field of drilling speed increase. To probe into rock breaking mechanism of high voltage electric pulse, this study establishes a two-dimensional numerical model of multi-physical field coupling electric breakdown of single pair of electrodes. The model reproduces the generation of plasma channels in homogeneous red sandstone from the coupling of current field, electric breakdown field and circuit field. This paper analyzes the effect of electrode pair angle, voltage and electrode spacing on rock electrical breakdown(that is, the formation of plasma channel in rock). The model includes the circuit structure parameters of pulse tool, the occurrence and development of electrical breakdown, and the relationship between electrical breakdown intensity and time. Results indicate that the plasma channel begins to sprout from the partial area near the top of the discharge electrode and develops towards the partial weak dielectric strength. With the voltage value of loading pulse increasing gradually, the time of electrical breakdown decreases gradually; comparatively, the equivalent failure volume of rock model increases gradually, and there is a positive correlation between them. On the precondition that the rock can be electrically broken, increasing the electrode spacing can improve the rock breaking efficiency of high voltage electric pulse. The equivalent failure volume of rock shows significant fluctuations during the gradual increase of electrode inclination angle of discharge electrode, and its extreme value mostly appears in the range of electrode inclination angle of 35°~ 55°. To further promote the industrial application of high-voltage electric pulse rock breaking, this paper proposes a three-dimensional numerical model of multi-physical field coupling dynamic electric breakdown of red sandstone based on two-dimensional model, reproducing the appearance of the fracture crater in the rock during the rock breaking process with electrode bit. At the same time, the self-designed coaxial electrode bit is selected for experiments of electric breakdown, and the laboratory experimental results of electric breakdown confirm the simulation experimental results.

-

Key words:

- high voltage electric pulse /

- rock breaking /

- electrode bit /

- electric breakdown /

- plasma channel

-

表 1 电极、水、岩石和绝缘套筒材料属性

Table 1. Material properties of electrode, water and insulating sleeve

材料 相对介电常数 电导率/(S·m-1) 比热容/[J·(kg·K)-1] 密度/(kg·m-3) 导热系数/[W·(m·K)-1] 水 80 0.001 25 4 180 1 000 0.59 电极 1 5.7×107 385 8 960 400 绝缘材料 4 0 1 700 1 150 0.26 岩石 5 4×10-5 750 2 600 3.14 表 2 仿真实验各正交参数和变量的详细信息

Table 2. Specifics of orthogonal parameters and variables in simulation experiment

变量种类 具体参数 电极倾角θ/(°) 0 10 20 30 40 50 60 70 80 90 电压U0/kV 100 110 120 130 140 150 电极间距Ld/mm 10 12.5 15 17.5 20 表 3 砂岩岩样的材料参数

Table 3. Material parameters of sandstone samples

参数项 砂岩 参数值 单位 杨氏模量 35 GPa 泊松比 0.2 — 相对介电常数 5 — 电导率 4×10-5 S/m 密度 2 500 kg/m3 孔隙率 12% — 空间体积能密度阈值 5.5 kJ/m3 -

[1] 祝效华, 刘伟吉. 旋冲钻井技术的破岩及提速机理[J]. 石油学报, 2018, 39(2): 216-222. https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB201802010.htmZhu Xiaohua, Liu Weiji. Rock breaking and ROP rising mechanism of rotary-percussive drilling technology[J]. Acta Petrolei Sinica, 2018, 39(2): 216-222. https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB201802010.htm [2] 魏迎春, 王亚东, 张劲, 等. 煤层气水平井钻井工程因素对煤粉产出影响的数值模拟: 以柳林区块为例[J]. 矿业科学学报, 2022, 7(6): 670-679. doi: 10.19606/j.cnki.jmst.2022.06.004Wei Yingchun, Wang Yadong, Zhang Jin, et al. Numerical simulation on the effect of drilling engineering factors on coal fines output in coalbed methane horizontal wells: a case study of Liulin block[J]. Journal of Mining Science and Technology, 2022, 7(6): 670-679. doi: 10.19606/j.cnki.jmst.2022.06.004 [3] 刘淑琴, 畅志兵, 刘金昌. 深部煤炭原位气化开采关键技术及发展前景[J]. 矿业科学学报, 2021, 6(3): 261-270. doi: 10.19606/j.cnki.jmst.2021.03.002Liu Shuqin, Chang Zhibing, Liu Jinchang. Key technologies and prospect for in situ gasification mining of deep coal resources[J]. Journal of Mining Science and Technology, 2021, 6(3): 261-270. doi: 10.19606/j.cnki.jmst.2021.03.002 [4] 左建平, 陈岩, 孙运江, 等. 深部煤岩组合体整体破坏的非线性模型研究[J]. 矿业科学学报, 2017, 2(1): 17-24. http://kykxxb.cumtb.edu.cn/article/id/43Zuo Jianping, Chen Yan, Sun Yunjiang, et al. Investigation on whole failure nonlinear model for deep coal-rock combined bodies[J]. Journal of Mining Science and Technology, 2017, 2(1): 17-24. http://kykxxb.cumtb.edu.cn/article/id/43 [5] Hu W R, Bao J W, Hu B. Trend and progress in global oil and gas exploration[J]. Petroleum Exploration and Development, 2013, 40(4): 439-443. doi: 10.1016/S1876-3804(13)60055-5 [6] Boev S, Vajov V, Levchenko B, et al. Electropulse technology of material destruction and boring[C]// Digest of Technical Papers. 11th IEEE International Pulsed Power Conference(Cat. No. 97CH36127). Baltimore, MD, USA. IEEE, 2002: 220-225. [7] Boev S, Vajov V, Jgun D, et al. Destruction of granite and concrete in water with pulse electric discharges[C]// Digest of Technical Papers. 12th IEEE International Pulsed Power Conference(Cat. No. 99CH36358). Monterey, CA, USA. IEEE, 2002: 1369-1371. [8] Maker V, Layke J. Gastrointestinal injury secondary to extracorporeal shock wave lithotripsy: a review of the literature since its inception[J]. Journal of the American College of Surgeons, 2004, 198(1): 128-135. doi: 10.1016/j.jamcollsurg.2003.06.006 [9] Cho S H, Cheong S S, Yokota M, et al. The dynamic fracture process in rocks under high-voltage pulse fragmentation[J]. Rock Mechanics and Rock Engineering, 2016, 49(10): 3841-3853. doi: 10.1007/s00603-016-1031-z [10] Usov A, Tsukerman V. Prospective of electric impulse processes for the study of the structure and processing of mineral raw materials[M]. Developments in Mineral Processing. Amsterdam: Elsevier, 2000. [11] Burkin V V, Kuznetsova N S, Lopatin V V. Analysis of mechanisms of rock destruction in electro discharge drilling[J]. Izvestja Vuzov Phys, 2006, 11: 507-10. [12] Usmanov G Z, Lopatin V V, Noskov M D, et al. Simulation of electrical discharge development at interface of solid and liquid dielectric[J]. Izv. Vyssh. Uchebn. Zaved. Fiz, 2006, 10: 231-234. [13] Lopatin V V, Noskov M D, Usmanov G Z, et al. Modeling of impulse electric discharge propagation in a condensed dielectric[J]. Russian Physics Journal, 2006, 49(3): 243-250. doi: 10.1007/s11182-006-0097-6 [14] Zhu X H, Luo Y X, Liu W J. On the rock-breaking mechanism of plasma channel drilling technology[J]. Journal of Petroleum Science and Engineering, 2020, 194: 107356. doi: 10.1016/j.petrol.2020.107356 [15] Zhu X H, Luo Y X, Liu W J, et al. On the mechanism of high-voltage pulsed fragmentation from electrical breakdown process[J]. Rock Mechanics and Rock Engineering, 2021, 54(9): 4593-4616. doi: 10.1007/s00603-021-02537-5 [16] Andres U. Electrical disintegration of rock[J]. Mineral Processing and Extractive Metallurgy Review, 1995, 14(2): 87-110. [17] Andres U, Timoshkin I, Jirestig J, et al. Liberation of valuable inclusions in ores and slags by electrical pulses[J]. Powder Technology, 2001, 114(1/2/3): 40-50. [18] Andres U, Timoshkin I, Soloviev M. Energy consumption and liberation of minerals in explosive electrical breakdown of ores[J]. Mineral Processing and Extractive Metallurgy, 2001, 110(3): 149-157. [19] Ezzat M, Adams B M, Saar M O, et al. Numerical modeling of the effects of pore characteristics on the electric breakdown of rock for plasma pulse geo drilling[J]. Energies, 2021, 15(1): 250. [20] Zhu X H, Luo Y X, Liu W J, et al. Numerical electric breakdown model of heterogeneous granite for electro-pulse-boring[J]. International Journal of Rock Mechanics and Mining Sciences, 2022, 154: 105128. [21] 祝效华, 罗云旭, 刘伟吉, 等. 等离子体电脉冲钻井破岩机理的电击穿实验与数值模拟方法[J]. 石油学报, 2020, 41(9): 1146-1162. https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB202009013.htmZhu Xiaohua, Luo Yunxu, Liu Weiji, et al. Electrical breakdown experiment and numerical simulation method of rock-breaking mechanism of plasma electric pulse drilling[J]. Acta Petrolei Sinica, 2020, 41(9): 1146-1162. https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB202009013.htm [22] Vorob'ev G A. Electrical breakdown in solid dielectrics[J]. Physics of the Solid State, 2005, 47(6): 1083. [23] Mesyats G A. On the nature of the Vorob'evs effect in pulse breakdown of solid dielectrics[J]. Technical Physics Letters, 2005, 31(12): 1061-1064. [24] Petrov Y V. Incubation time criterion and the pulsed strength of continua: fracture, cavitation, and electrical breakdown[J]. Doklady Physics, 2004, 49(4): 246-249. [25] Petrov Y, Smirnov I. General effects of pulse electric breakdown of dielectric gaps and dynamic failure of continuous media[J]. Procedia Structural Integrity, 2016, 2: 430-437. [26] Liu W J, Zhang Y J, Zhu X H, et al. The influence of pore characteristics on rock fragmentation mechanism by high-voltage electric pulse[J]. Plasma Science and Technology, 2023, 25(5): 055502. [27] Zhu X H, Chen M Q, Liu W J, et al. The fragmentation mechanism of heterogeneous granite by high-voltage electrical pulses[J]. Rock Mechanics and Rock Engineering, 2022, 55(7): 4351-4372. -

下载:

下载: