Analysis on roof sag of pre-driven recovery room based on energy calculation

-

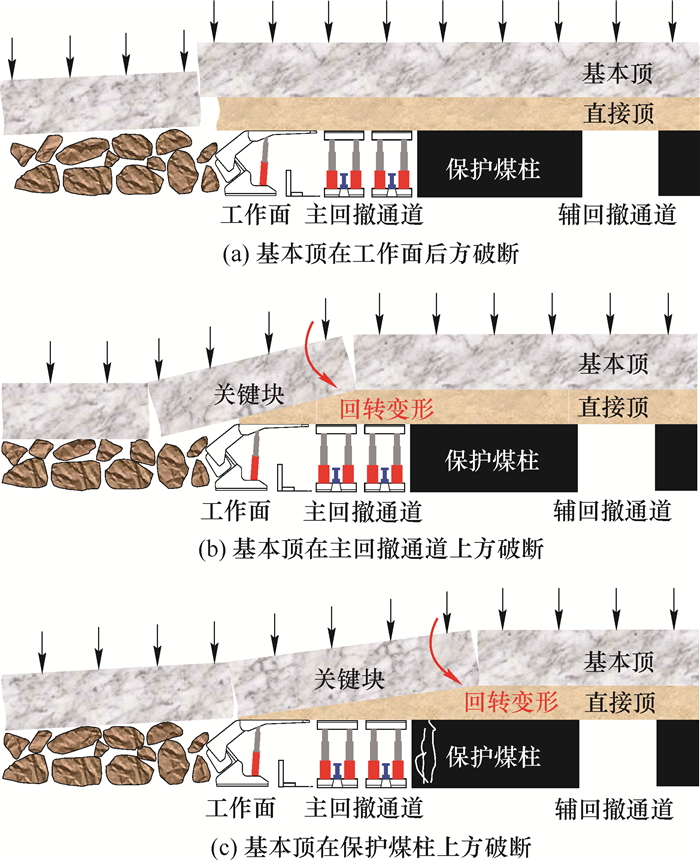

摘要: 采用预掘回撤通道技术的综采工作面在末采阶段易发生顶板大变形而引发压架事故。本文基于工作面贯通后的3种基本顶破坏形式,建立了不同的回撤通道顶板力学模型,通过分析顶板变形过程中的能量释放与做功过程,求得不同基本顶破坏形式下的回撤通道直接顶下沉量。结合张家峁煤矿N14201工作面回撤通道顶板大变形案例,分析了不同顶板力学模型的影响因素,发现基本顶破断位置、关键块及其上覆岩层厚度、关键块回转角和支护强度对回撤通道顶板下沉量影响显著,确定了张家峁煤矿N14201工作面发生压架事故的原因,即基本顶在保护煤柱上方4~6 m范围内破断以及上部3-1煤层开采导致主关键层破断失稳。Abstract: The fully mechanized mining face adopting pre-driven recovery room is prone to large roof deformation at the final mining stage, which will lead to support crushing accidents. Based on the three main roof failure forms after longwall face entered recovery room, this paper established different mechanical models for roof sag of the recovery room. By analyzing energy release and work process in roof deformation, this paper obtained the immediate roof sag of recovery room under different main roof failure forms. Taking the large roof deformation and support crushing accident of recovery room in the N14201 longwall face of Zhangjiamao Coal Mine as example for analysis, this paper analyzed the influencing factors of the models and found that the main roof break position, the thickness of key block and its overlying strata, the rotation angle of key block and the supporting intensity have significant impact on the roof sag of recovery room. The research results confirmed that the reason for the support crushing accident in N14201 longwall face of Zhangjiamao Coal Mine: the main roof is broken within 4~6 m above the protective coal pillar, and the main key stratum is broken and unstable due to the mining of upper 3-1 coal seam.

-

表 1 N14201工作面末采阶段周期来压统计

Table 1. Periodic weighting statistics at the final mining stage of N14201 longwall face

周期来压次数 来压位置/m 来压步距/m 1 99.0 12.5 2 80.1 18.9 3 62.8 17.3 4 49.0 13.8 5 41.5 7.5 6 24.0 17.5 7 6.0 18.0 8(末次来压) -9.1 15.1 末次来压基本顶破断位置d/m -3.9 表 2 N14201工作面和回撤通道参数

Table 2. Parameters of N14201 longwall face and recovery room

类型 参数 取值 煤层赋存 覆岩平均容重γ /(kN·m-3) 25 煤层埋深H/m 131 关键块上覆岩层厚度Hm/m 72 关键块回转角α/(°) 15 直接顶厚度hi/m 2.34 直接顶弹性模量Ei/GPa 17 煤层弹性模量Ec/GPa 7 应力集中系数k 2.5 内摩擦系数f 0.8 侧压力系数λ 0.4 工程和支护 掩护式支架控顶距Wl/m 6 主回撤通道宽度Wr/m 5.2 主回撤通道高度hr/m 3.5 掩护式支架支护强度fs/kPa 872 垛式支架支护强度fc/kPa 845 -

[1] 赵军. 大断面回撤通道锚杆支护技术与应用[J]. 煤炭科学技术, 2005, 33(11): 5-7. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ200511001.htmZhao Jun. Bolt support technology for large cross sectional equipment remove gateway and application[J]. Coal Science and Technology, 2005, 33(11): 5-7. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ200511001.htm [2] 贺安民. 综采工作面回撤"辅巷多通道"工艺设计的应用[J]. 煤炭工程, 2007, 39(10): 5-6. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ200710000.htmHe Anmin. Application of "multi-channel auxiliary roadway" technology design in fully mechanized mining face withdrawal[J]. Coal Engineering, 2007, 39(10): 5-6. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ200710000.htm [3] 张炜, 张东升, 王旭锋, 等. 大采高工作面大断面回撤通道联合支护效果模拟分析[J]. 煤炭工程, 2009, 41(3): 64-66. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ200903038.htmZhang Wei, Zhang Dongsheng, Wang Xufeng, et al. Simulation analysis on results of combined support applied to large cross-section withdrawal roadway in large mining height coalface[J]. Coal Engineering, 2009, 41(3): 64-66. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ200903038.htm [4] Kang H P, Lü H W, Zhang X, et al. Evaluation of the ground response of a pre-driven longwall recovery room supported by concrete cribs[J]. Rock Mechanics and Rock Engineering, 2016, 49(3): 1025-1040. doi: 10.1007/s00603-015-0782-2 [5] 舒凑先, 姜福兴, 韩跃勇, 等. 深部重型综采面长距离多联巷快速回撤技术研究[J]. 采矿与安全工程学报, 2018, 35(3): 473-480. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201803005.htmShu Couxian, Jiang Fuxing, Han Yueyong, et al. Long-distance multi-crosscut rapid-retracement technique in deep heavy fully mechanized face[J]. Journal of Mining & Safety Engineering, 2018, 35(3): 473-480. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201803005.htm [6] 彭林军, 岳宁, 安亮, 等. 超大采高综采工作面回撤通道支护技术研究[J]. 煤炭科学技术, 2022, 50(6): 204-210. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202206020.htmPeng Linjun, Yue Ning, An Liang, et al. Study on support of retractable channel in fully-mechanized mining face with super large mining height[J]. Coal Science and Technology, 2022, 50(6): 204-210. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202206020.htm [7] 王志强, 王树帅, 苏泽华, 等. 走向工作面贯通上山与支架快速回撤技术[J]. 中国安全生产科学技术, 2020, 16(1): 18-24. https://www.cnki.com.cn/Article/CJFDTOTAL-LDBK202001004.htmWang Zhiqiang, Wang Shushuai, Su Zehua, et al. Technologies of uphill transfixion and rapid retracing of brackets in along strike working face[J]. Journal of Safety Science and Technology, 2020, 16(1): 18-24. https://www.cnki.com.cn/Article/CJFDTOTAL-LDBK202001004.htm [8] 王晓振, 鞠金峰, 许家林. 神东浅埋综采面末采段让压开采原理及应用[J]. 采矿与安全工程学报, 2012, 29(2): 151-156. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201202000.htmWang Xiaozhen, Ju Jinfeng, Xu Jialin. Theory and applicable of yield mining at ending stage of fully-mechanized face in shallow seam at Shendong Mine area[J]. Journal of Mining & Safety Engineering, 2012, 29(2): 151-156. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201202000.htm [9] Zhang F T, Wang X Y, Bai J B, et al. Fixed-length roof cutting with vertical hydraulic fracture based on the stress shadow effect: a case study[J]. International Journal of Mining Science and Technology, 2022, 32(2): 295-308. [10] 吕华文. 预掘回撤通道稳定性机理分析及应用[J]. 煤炭学报, 2014, 39(S1): 50-56. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2014S1009.htmLü Huawen. The mechanism of stability of pre-driven rooms and the practical techniques[J]. Journal of China Coal Society, 2014, 39(S1): 50-56. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2014S1009.htm [11] 谷拴成, 黄荣宾, 李金华, 等. 工作面贯通前矿压调整时剩余煤柱稳定性分析[J]. 采矿与安全工程学报, 2017, 34(1): 60-66. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201701009.htmGu Shuancheng, Huang Rongbin, Li Jinhua, et al. Stability analysis of un-mined coal pillars during the pressure adjustment prior to working face transfixion[J]. Journal of Mining & Safety Engineering, 2017, 34(1): 60-66. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201701009.htm [12] 王方田, 邵栋梁, 牛滕冲, 等. 浅埋高强度开采回撤巷道煤柱受载特征及累积损伤机制[J]. 岩石力学与工程学报, 2022, 41(6): 1148-1159. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202206007.htmWang Fangtian, Shao Dongliang, Niu Tengchong, et al. Progressive loading characteristics and accumulated damage mechanisms of shallow-buried coal pillars in withdrawal roadways with high-strength mining effect[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(6): 1148-1159. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202206007.htm [13] 杨惠斌, 王志刚, 赵银虎, 等. 大采高综采工作面回撤通道顶板控制技术研究[J]. 矿业安全与环保, 2014, 41(5): 59-61, 68. https://www.cnki.com.cn/Article/CJFDTOTAL-ENER201405016.htmYang Huibin, Wang Zhigang, Zhao Yinhu, et al. Study on roof control technology for withdrawal passageway in fully mechanized coal face with large mining height[J]. Mining Safety & Environmental Protection, 2014, 41(5): 59-61, 68. https://www.cnki.com.cn/Article/CJFDTOTAL-ENER201405016.htm [14] 万镇. 综采工作面设备回撤通道围岩控制研究[D]. 青岛: 山东科技大学, 2009. [15] 王树帅, 王志强, 黄鑫, 等. 回撤通道直接顶下沉量计算及其影响因素分析[J]. 矿业科学学报, 2021, 6(4): 409-417. doi: 10.19606/j.cnki.jmst.2021.04.005Wang Shushuai, Wang Zhiqiang, Huang Xin, et al. Calculation of direct roof subsidence of retracement channel and analysis of its influencing factors[J]. Journal of Mining Science and Technology, 2021, 6(4): 409-417. doi: 10.19606/j.cnki.jmst.2021.04.005 [16] 程占博, 孔德中, 杨敬虎. 综放工作面厚硬顶板破断特征与支架工作阻力确定[J]. 矿业科学学报, 2016, 1(2): 172-180. http://kykxxb.cumtb.edu.cn/article/id/24Cheng Zhanbo, Kong Dezhong, Yang Jinghu. The breaking characteristics of thick-hard roof and determination of support capacity in fully mechanized caving face[J]. Journal of Mining Science and Technology, 2016, 1(2): 172-180. http://kykxxb.cumtb.edu.cn/article/id/24 [17] Wang B N, Dang F N, Gu S C, et al. Method for determining the width of protective coal pillar in the pre-driven longwall recovery room considering main roof failure form[J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 130: 104340. [18] 陈炎光, 陆士良. 中国煤矿巷道围岩控制[M]. 徐州: 中国矿业大学出版社, 1994: 133-135. [19] 陈勇. 沿空留巷围岩结构运动稳定机理与控制研究[D]. 徐州: 中国矿业大学, 2012. [20] 付玉平, 宋选民, 邢平伟, 等. 大采高采场顶板断裂关键块稳定性分析[J]. 煤炭学报, 2009, 34(8): 1027-1031. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200908003.htmFu Yuping, Song Xuanmin, Xing Pingwei, et al. Stability analysis on main roof key block in large mining height workface[J]. Journal of China Coal Society, 2009, 34(8): 1027-1031. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200908003.htm [21] 李永亮, 王宇轩, 林海, 等. 两侧采空巷道挤压变形机理与控制对策[J]. 矿业科学学报, 2020, 5(5): 511-518. doi: 10.19606/j.cnki.jmst.2020.05.005Li Yongliang, Wang Yuxuan, Lin Hai, et al. Squeezing deformation mechanism and control technology of roadway between two goafs[J]. Journal of Mining Science and Technology, 2020, 5(5): 511-518. doi: 10.19606/j.cnki.jmst.2020.05.005 [22] 赵善坤, 李英杰, 柴海涛, 等. 陕蒙地区厚硬砂岩顶板定向水力压裂预割缝倾角优化及防冲实践[J]. 煤炭学报, 2020, 45(S1): 150-160. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2020S1016.htmZhao Shankun, Li Yingjie, Chai Haitao, et al. Pre-existing crack angle optimization of thick sandstone roof during directional hydraulic fracturing and its application to anti-rockburst in Shannxi and Inner Mongolia areas[J]. Journal of China Coal Society, 2020, 45(S1): 150-160. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2020S1016.htm [23] 高晓进, 李煜炜, 张振金, 等. 软岩巷道大变形双主动超前爆破预裂顶板防控技术[J]. 煤炭学报, 2020, 45(S2): 589-598. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2020S2006.htmGao Xiaojin, Li Yuwei, Zhang Zhenjin, et al. Prevention and control technology of pre-splitting roof by dual active advanced blasting in soft rock large deformation roadway[J]. Journal of China Coal Society, 2020, 45(S2): 589-598. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2020S2006.htm -

下载:

下载: