Multi-scale joint characterization of coal seam pore structure and its influence on movable fluid

-

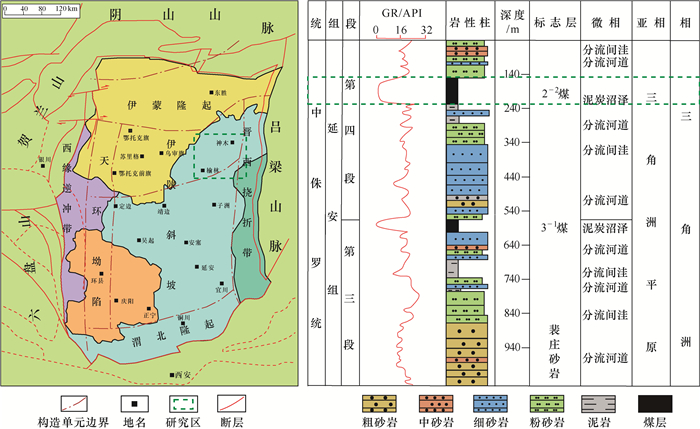

摘要: 微观孔隙结构影响着流体在煤层中的储存及渗流。为精确表征煤层微观孔隙结构特征,本文以鄂尔多斯盆地神木地区侏罗系延安组煤层为研究对象,采用核磁共振、CO2吸附和N2吸附手段,多尺度联合表征煤层的孔隙分布特征,并结合CT扫描技术对微观孔隙的连通性和均匀性进行研究。结果表明:煤的微孔是比表面积与孔容积的主要贡献者,介孔次之;核磁共振与吸附联合表征反映了微孔、介孔部分的孔径分布有较好的一致性,大孔部分差异较大;驱替核磁共振和CT在反映连通程度方面具有优势,且两者对于连通性的表征具有一致性,配位数以及渗流孔比例等参数可有效反映样品的连通程度;不同深度段煤层连通性不同,非均质性也不同;煤样束缚水饱和度与孔喉比存在良好的正相关性。可见,孔隙结构对流体的运移程度有很大影响,是研究及评价瓦斯赋存与渗流的基础。Abstract: Micro-pore structure affects the fluid storage and seepage in coal seams.In this paper, six samples from the Jurassic Yan'an Formation coal seam in the Shenmu area of the Ordos Basin were taken as the object of study.The pore distribution characteristics of coal seams were jointly characterized by NMR, CO2 adsorption and N2 adsorption at multiple scales, and the connectivity and homogeneity of microscopic pores were investigated by combining multi-scale joint characiterization with CT scanning.Results show that the micro-pores of coal are the main contributors to the specific surface area and pore volume, followed by meso-pores.There is a good uniformity in the pore size distribution of the micro-pores and meso-pores by combing NMR and adsorption, while considerable differences are found in the macro-pores.Displacement NMR and CT excel in reflecting the degree of connectivity, both of which are consistent in the characterization of connectivity.Parameters such as coordination number and seepage pore ratio can effectively reflect the degree of connectivity of the sample, whose patterns of connectivity is M6>M2>M12>M15>M10>M4.The saturation of bound water shows a satisfactory positive correlation with pore-throat ratio of coal samples.It can be seen that the pore structure has a great influence on the degree of fluid migration, which is the basis for studying and evaluating gas occurrence and seepage.

-

Key words:

- joint characterization /

- pore structure /

- NMR /

- gas adsorption /

- connectivity /

- movable fluid

-

表 1 煤质分析及物性基本参数

Table 1. Coal quality analysis and basic parameters of physical properties

煤矿 样号 深度/m 镜质体反射率/% 水分/% 灰分/% 挥发分/% 孔隙率/% 渗透率/mD 神木侏罗纪煤田 M2 220 0.57 6.09 15.32 41.92 8.571 5.103 M4 130 0.58 5.47 6.53 38.43 4.823 3.357 M6 230 0.60 6.29 4.37 36.88 13.220 8.476 M10 140 0.52 8.62 18.84 32.75 1.975 1.531 M12 180 0.63 4.26 15.35 31.28 5.828 3.518 M15 140 0.74 2.37 16.60 34.90 2.958 4.513 表 2 CO2吸附实验数据

Table 2. Test data of CO2 adsorption

样品编号 V1/(cm3·g-1) S1/(m2·g-1) M2 0.022 0 73.23 M4 0.015 6 51.42 M6 0.022 5 74.93 M10 0.021 4 72.47 M12 0.022 8 77.32 M15 0.021 2 71.29 注:V1为微孔的孔容;S1为微孔的比表面积。 表 3 N2吸附实验数据

Table 3. Test data of N2 adsorption

编号 Vz/(cm3·g-1) 阶段孔容/(cm3·g-1) Sz/(m2·g-1) 阶段比表面积/(m2·g-1) V1 V2 V3 S1 S2 S3 M2 0.034 3 0 0.033 0(96.2%) 0.001 3(3.8%) 14.696 1 0 14.659 0(99.7%) 0.037 1(0.3%) M4 0.031 9 0 0.030 4(95.9%) 0.001 5(4.1%) 12.210 7 0 12.168 8(99.6%) 0.041 9(0.4%) M6 0.046 3 0 0.044 4(95.9%) 0.001 9(4.1%) 19.901 7 0 19.854 3(99.8%) 0.047 4(0.2%) M10 0.013 4 0 0.012 8(95.5%) 0.000 6(4.5%) 5.343 7 0 5.327 1(99.7%) 0.016 6(0.3%) M12 0.036 3 0 0.034 8(95.8%) 0.001 5(4.2%) 14.996 4 0 14.953 3(99.7%) 0.043 1(0.3%) M15 0.025 6 0 0.024 6(96.1%) 0.001 0(3.9%) 9.285 0 0 9.254 0(99.6%) 0.003 0(0.4%) 注:Vz为总孔容;V1为微孔孔容;V2为介孔孔容;V3为大孔孔容;Sz为总比表面积;S1为微孔比表面积;S2为介孔比表面积;S3为大孔比表面积;括号中百分数为各类孔占比表面积或孔容的比例。 表 4 煤CT孔隙结构参数

Table 4. CT pore structure parameters of coal samples

参数 M2 M4 M6 M10 M12 M15 孔隙率/% 5.46 1.07 6.03 1.85 2.02 2.21 孔隙总数 36 987 32 000 40 165 2 833 5 913 33 385 喉道总数 476 238 838 574 76 385 孔隙半径/μm 最大值 4 200 1 736 4 260 2 450 1 810 2 690 最小值 10.4 10.4 10.4 10.4 10.4 10.4 平均值 35.5 33.1 37.5 33.3 35.2 32.3 喉道半径/μm 最大值 1 160 306 634 276 610 419 最小值 5.77 3.26 5.09 5.63 16.1 4.48 平均值 218 42 246 53 156 134 孔隙配位数 最大值 17 10 14 11 20 18 最小值 1 0 1 1 1 0 平均值 4.18 3.22 4.22 3.30 3.90 3.50 孔喉比 最大值 56 26 61 32 23 69 最小值 1 1 1 1 1 1 平均值 2.6 3.5 1.6 3.4 2.2 2.6 -

[1] 李传亮, 朱苏阳, 彭朝阳, 等. 煤层气井突然产气机理分析[J]. 岩性油气藏, 2017, 29(2): 145-149. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX201702018.htmLi Chuanliang, Zhu Suyang, Peng Chaoyang, et al. Mechanism of gas production rate outburst in coalbed methane wells[J]. Lithologic Reservoirs, 2017, 29(2): 145-149. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX201702018.htm [2] 王大曾. 瓦斯地质讲座第五讲瓦斯含量的测定、预测和煤与瓦斯突出的预测、预防[J]. 煤田地质与勘探, 1985, 13(5): 69-72. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT198505024.htmWang Dazeng. The fifth lecture on gas geology: determination and prediction of gas content and prediction and prevention of coal and gas outburst[J]. Coal Geology & Exploration, 1985, 13(5): 69-72. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT198505024.htm [3] 刘东娜. 大同煤田石炭二叠纪煤的煤岩学和煤地球化学研究[D]. 太原: 太原理工大学, 2007. [4] 汤中一. 煤的纳米结构特征探讨[D]. 南京: 南京大学, 2014. [5] 解维伟, 王卫东. 关于煤化学与煤质分析课程建设的探讨[J]. 中国科教创新导刊, 2011(26): 54. doi: 10.3969/j.issn.1673-9795.2011.26.043Xie Weiwei, Wang Weidong. Discussion on the course construction of coal chemistry and coal quality analysis[J]. China Education Innovation Herald, 2011(26): 54. doi: 10.3969/j.issn.1673-9795.2011.26.043 [6] Hou L, Cody G, Hatcher P, et al. Imaging the microstructure of low rank coals: a study combining nuclear magnetic resonance, scanning electron and optical microscopic imaging[J]. Fuel, 1994, 73(2): 199-203. doi: 10.1016/0016-2361(94)90114-7 [7] 折海成, 刘思其, 胡再强. 基于SEM数字图像的岩石结构特征分析方法[J]. 水电能源科学, 2022, 40(11): 167-170, 175. https://www.cnki.com.cn/Article/CJFDTOTAL-SDNY202211039.htmShe Haicheng, Liu Siqi, Hu Zaiqiang. An analysis method of rock structure characteristics based on SEM digital images[J]. Water Resources and Power, 2022, 40(11): 167-170, 175. https://www.cnki.com.cn/Article/CJFDTOTAL-SDNY202211039.htm [8] Zou M J, Wei C T, Zhang M, et al. Classifying coal pores and estimating reservoir parameters by nuclear magnetic resonance and mercury intrusion porosimetry[J]. Energy & Fuels, 2013, 27(7): 3699-3708. [9] 戚灵灵, 王兆丰, 杨宏民, 等. 基于低温氮吸附法和压汞法的煤样孔隙研究[J]. 煤炭科学技术, 2012, 40(8): 36-39, 87. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201208009.htmQi Lingling, Wang Zhaofeng, Yang Hongmin, et al. Study on porosity of coal samples based on low temperature nitrogen adsorption method and mercury porosimetry[J]. Coal Science and Technology, 2012, 40(8): 36-39, 87. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201208009.htm [10] Li Y H, Lu G Q, Rudolph V. Compressibility and fractal dimension of fine coal particles in relation to pore structure characterisation using mercury porosimetry[J]. Particle & Particle Systems Characterization, 1999, 16(1): 25-31. [11] Hu F L, Zhou C C, Li C L, et al. Water spectrum method of NMR logging for identifying fluids[J]. Petroleum Exploration and Development, 2016, 43(2): 268-276. doi: 10.1016/S1876-3804(16)30030-1 [12] 李祥春, 高佳星, 张爽, 等. 基于扫描电镜、孔隙-裂隙分析系统和气体吸附的煤孔隙结构联合表征[J]. 地球科学, 2022, 47(5): 1876-1889. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX202205024.htmLi Xiangchun, Gao Jiaxing, Zhang Shuang, et al. Combined characterization of scanning electron microscopy, pore and crack analysis system, and gas adsorption on pore structure of coal with different volatilization[J]. Earth Science, 2022, 47(5): 1876-1889. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX202205024.htm [13] Wang Y, Pu J, Wang L H, et al. Characterization of typical 3D pore networks of Jiulaodong formation shale using nano-transmission X-ray microscopy[J]. Fuel, 2016, 170: 84-91. doi: 10.1016/j.fuel.2015.11.086 [14] 关欣, 刘育伟, 任重阳, 等. 基于CT三维重构的无烟煤孔隙结构及连通性特征对比表征[J]. 非常规油气, 2023, 10(1): 69-76. https://www.cnki.com.cn/Article/CJFDTOTAL-FCYQ202301009.htmGuan Xin, Liu Yuwei, Ren Chongyang, et al. Characterization and comparison of pore structure and connectivity of anthracite based on CT three-dimensional reconstruction[J]. Unconventional Oil & Gas, 2023, 10(1): 69-76. https://www.cnki.com.cn/Article/CJFDTOTAL-FCYQ202301009.htm [15] 车玉燕, 邹冠贵, 殷裁云, 等. 雨汪井田超压含煤地层孔隙特征及孔隙体积模量演变规律[J]. 矿业科学学报, 2022, 7(3): 275-285. doi: 10.19606/j.cnki.jmst.2022.03.002Che Yuyan, Zou Guangui, Yin Caiyun, et al. The evolution law of pore characteristics and pore bulk moulus for overpressured coal-bearing formation in Yuwang Minefield[J]. Journal of Mining Science and Technology, 2022, 7(3): 275-285. doi: 10.19606/j.cnki.jmst.2022.03.002 [16] Okolo G N, Everson R C, Neomagus H W J P, et al. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques[J]. Fuel, 2015, 141: 293-304. doi: 10.1016/j.fuel.2014.10.046 [17] 聂百胜, 王科迪, 樊堉, 等. 基于小角X射线散射技术计算不同孔形的煤孔隙特征比较研究[J]. 矿业科学学报, 2020, 5(3): 284-290. http://kykxxb.cumtb.edu.cn/article/id/291Nie Baisheng, Wang Kedi, Fan Yu, et al. The comparative study on calculation of coal pore characteristicsof different pore shapes based SAXS[J]. Journal of Mining Science and Technology, 2020, 5(3): 284-290. http://kykxxb.cumtb.edu.cn/article/id/291 [18] 文志刚, 罗雨舒, 刘江艳, 等. 陇东地区三叠系长7段页岩油储层孔隙结构特征及成因机制[J]. 岩性油气藏, 2022, 34(6): 47-59. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202206004.htmWen Zhigang, Luo Yushu, Liu Jiangyan, et al. Pore structure characteristics and genetic mechanism of Triassic Chang 7 shale oil reservoir in Longdong area[J]. Lithologic Reservoirs, 2022, 34(6): 47-59. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202206004.htm [19] 秦雷, 王平, 林海飞, 等. 基于氮气吸附和压汞法液氮冻结煤体孔隙结构精细化表征研究[J]. 西安科技大学学报, 2020, 40(6): 945-952, 959. https://www.cnki.com.cn/Article/CJFDTOTAL-XKXB202006003.htmQin Lei, Wang Ping, Lin Haifei, et al. Advanced characterization of pore structure of liquid nitrogen frozen coal using nitrogen adsorption and mercury intrusion methods[J]. Journal of Xi'an University of Science and Technology, 2020, 40(6): 945-952, 959. https://www.cnki.com.cn/Article/CJFDTOTAL-XKXB202006003.htm [20] 姚艳斌, 刘大锰, 蔡益栋, 等. 基于NMR和X-CT的煤的孔裂隙精细定量表征[J]. 中国科学: 地球科学, 2010, 40(11): 1598-1607. https://www.cnki.com.cn/Article/CJFDTOTAL-JDXK201011014.htmYao Yanbin, Liu Dameng, Cai Yidong, et al. Fine quantitative characterization of coal pores and fractures based on NMR and X-CT[J]. Science in China Series D: Earth Sciences, 2010, 40(11): 1598-1607. https://www.cnki.com.cn/Article/CJFDTOTAL-JDXK201011014.htm [21] 曾宏斌, 王芙蓉, 罗京, 等. 基于低温氮气吸附和高压压汞表征潜江凹陷盐间页岩油储层孔隙结构特征[J]. 地质科技通报, 2021, 40(5): 242-252. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ202105025.htmZeng Hongbin, Wang Furong, Luo Jing, et al. Characteristics of pore structure of intersalt shale oil reservoir by low temperature nitrogen adsorption and high pressure mercury pressure methods in Qianjiang Sag[J]. Bulletin of Geological Science and Technology, 2021, 40(5): 242-252. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ202105025.htm [22] 刘翰林, 邹才能, 邱振, 等. 鄂尔多斯盆地延长组7段3亚段异常高有机质沉积富集因素[J]. 石油学报, 2022, 43(11): 1520-1541. https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB202211013.htmLiu Hanlin, Zou Caineng, Qiu Zhen, et al. Sedimentary enrichment factors of extraordinarily high organic matter in the sub-member 3 of Member 7 of Yanchang Formation, Ordos Basin[J]. Acta Petrolei Sinica, 2022, 43(11): 1520-1541. https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB202211013.htm [23] 张岳桥, 廖昌珍. 晚中生代—新生代构造体制转换与鄂尔多斯盆地改造[J]. 中国地质, 2006, 33(1): 28-40. https://www.cnki.com.cn/Article/CJFDTOTAL-DIZI200601002.htmZhang Yueqiao, Liao Changzhen. Transition of the Late Mesozoic-Cenozoic tectonic regimes and modification of the Ordos Basin[J]. Geology in China, 2006, 33(1): 28-40. https://www.cnki.com.cn/Article/CJFDTOTAL-DIZI200601002.htm [24] Ji W M, Song Y, Jiang Z X, et al. Geological controls and estimation algorithms of lacustrine shale gas adsorption capacity: a case study of the Triassic strata in the southeastern Ordos Basin, China[J]. International Journal of Coal Geology, 2014, 134: 61-73. [25] 薛军民, 高胜利, 高鹏. 鄂尔多斯盆地神木地区上古生界煤储层特征及含气潜力[J]. 石油实验地质, 2008, 30(1): 37-40, 46. https://www.cnki.com.cn/Article/CJFDTOTAL-SYSD200801007.htmXue Junmin, Gao Shengli, Gao Peng. Characteristics of the upper Paleozoic coal reservoir and its gas-bearing potential in Shenmu, the Ordos Basin[J]. Petroleum Geology & Experiment, 2008, 30(1): 37-40, 46. https://www.cnki.com.cn/Article/CJFDTOTAL-SYSD200801007.htm [26] Xin F D, Xu H, Tang D Z, et al. Pore structure evolution of low-rank coal in China[J]. International Journal of Coal Geology, 2019, 205: 126-139. doi: 10.1016/j.coal.2019.02.013 [27] 石耀军. 安塞油田王窑南长6段油层有利区主控因素分析[D]. 武汉: 中国地质大学(武汉), 2013. [28] 邱隆伟, 杨保良, 张阳, 等. 湖泊水位对三角洲前缘主要砂体类型的影响: 以鄂尔多斯盆地神木地区侏罗系延安组剖面为例[J]. 古地理学报, 2016, 18(6): 939-950. https://www.cnki.com.cn/Article/CJFDTOTAL-GDLX201606004.htmQiu Longwei, Yang Baoliang, Zhang Yang, et al. Lake level effect on main sandbodies of delta front: a case study from outcrops of the Jurassic Yan'an Formation in Shenmu area, Ordos Basin[J]. Journal of Palaeogeography, 2016, 18(6): 939-950. https://www.cnki.com.cn/Article/CJFDTOTAL-GDLX201606004.htm [29] Thommes M. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution(IUPAC Technical Report)[J]. Pure and Applied Chemistry, 2016, 87(1): 25-25. [30] 肖佃师, 赵仁文, 杨潇, 等. 海相页岩气储层孔隙表征、分类及贡献[J]. 石油与天然气地质, 2019, 40(6): 1215-1225. https://www.cnki.com.cn/Article/CJFDTOTAL-SYYT201906006.htmXiao Dianshi, Zhao Renwen, Yang Xiao, et al. Characterization, classification and contribution of marine shale gas reservoirs[J]. Oil & Gas Geology, 2019, 40(6): 1215-1225. https://www.cnki.com.cn/Article/CJFDTOTAL-SYYT201906006.htm [31] 江泽标, 彭鑫, 韦善阳, 等. 基于氮吸附、压汞联合试验的CO2致裂对煤岩孔隙的影响[J]. 安全与环境学报, 2021, 21(01): 101-108. https://www.cnki.com.cn/Article/CJFDTOTAL-AQHJ202101014.htmJiang Zebiao, Peng Xin, Wei Shanyang, et al. Influence of CO2 cracking on the coal and rock pore based on the nitrogen adsorption and mercury press combined experiment[J]. Journal of Safety and Environment, 2021, 21(1): 101-108. https://www.cnki.com.cn/Article/CJFDTOTAL-AQHJ202101014.htm [32] 张征, 商少石, 张志炳, 等. 基于氮吸附法的页岩有机孔隙结构表征[J]. 地质与勘探, 2021, 57(6): 1408-1415. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT202106021.htmZhang Zheng, Shang Shaoshi, Zhang Zhibing, et al. Characterization of shale organic-pore structure using the nitrogen adsorption method[J]. Geology and Exploration, 2021, 57(6): 1408-1415. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT202106021.htm [33] 蔺亚兵, 贾雪梅, 马东民. 基于液氮吸附法对煤的孔隙特征研究与应用[J]. 煤炭科学技术, 2016, 44(3): 135-140. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201603026.htmLin Yabing, Jia Xuemei, Ma Dongmin. Study and application of coal pore features based on liquid nitrogen adsorption method[J]. Coal Science and Technology, 2016, 44(3): 135-140. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201603026.htm [34] 杨明, 柳磊, 张学博, 等. 不同阶煤孔隙结构与流体特性的核磁共振试验研究[J]. 中国安全科学学报, 2021, 31(1): 81-88. https://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK202101014.htmYang Ming, Liu Lei, Zhang Xuebo, et al. Nuclear magnetic resonance experimental study on pore structure and fluid characteristics of coal at different ranks[J]. China Safety Science Journal, 2021, 31(1): 81-88. https://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK202101014.htm [35] 王传涛, 党悦晨, 高飞, 等. 低阶煤宏观煤岩组分孔隙结构特征研究[J]. 延安大学学报: 自然科学版, 2022, 41(3): 38-45. https://www.cnki.com.cn/Article/CJFDTOTAL-YSZR202203006.htmWang Chuantao, Dang Yuechen, Gao Fei, et al. Study on macroscopic pore structure characteristics of low-rank coal[J]. Journal of Yan'an University: Natural Science Edition, 2022, 41(3): 38-45. https://www.cnki.com.cn/Article/CJFDTOTAL-YSZR202203006.htm [36] 李阳, 张玉贵, 张浪, 等. 基于压汞、低温N2吸附和CO2吸附的构造煤孔隙结构表征[J]. 煤炭学报, 2019, 44(4): 1188-1196. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201904025.htmLi Yang, Zhang Yugui, Zhang Lang, et al. Characterization on pore structure of tectonic coals based on the method of mercury intrusion, carbon dioxide adsorption and nitrogen adsorption[J]. Journal of China Coal Society, 2019, 44(4): 1188-1196. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201904025.htm [37] 杨甫, 贺丹, 马东民, 等. 低阶煤储层微观孔隙结构多尺度联合表征[J]. 岩性油气藏, 2020, 32(3): 14-23. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202003002.htmYang Fu, He Dan, Ma Dongmin, et al. Multi-scale joint characterization of micro-pore structure of low-rank coal reservoir[J]. Lithologic Reservoirs, 2020, 32(3): 14-23. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202003002.htm [38] 胡彪, 程远平, 王亮. 原生结构煤与构造煤孔隙结构与瓦斯扩散特性研究[J]. 煤炭科学技术, 2018, 46(3): 103-107, 24. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201803017.htmHu Biao, Cheng Yuanping, Wang Liang. Study on porous structure and gas diffusion characteristics of primary structure coal and tectonic coal[J]. Coal Science and Technology, 2018, 46(3): 103-107, 24. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201803017.htm [39] 杨明, 柳磊, 刘佳佳, 等. 中阶煤孔隙结构的氮吸附-压汞-核磁共振联合表征研究[J]. 煤炭科学技术, 2021, 49(5): 67-74. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202105010.htmYang Ming, Liu Lei, Liu Jiajia, et al. Study on joint characterization of pore structure of middle-rank coal by nitrogen adsorption-mercury intrusion-NMR[J]. Coal Science and Technology, 2021, 49(5): 67-74. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202105010.htm [40] 桑树勋, 朱炎铭, 张时音, 等. 煤吸附气体的固气作用机理(I): 煤孔隙结构与固气作用[J]. 天然气工业, 2005, 25(1): 13-15, 205. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG200501004.htmSang Shuxun, Zhu Yanming, Zhang Shiyin, et al. Solid-gas interaction mechanism of coal-adsorbed gas(i)—coal pore structure and solid-gas interaction[J]. Natural Gas Industry, 2005, 25(1): 13-15, 205. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG200501004.htm [41] 夏青松, 陆江, 杨鹏, 等. 柴达木盆地英西地区渐新统下干柴沟组上段储层微观孔隙结构特征[J]. 岩性油气藏, 2023, 35(1): 132-144. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202301012.htmXia Qingsong, Lu Jiang, Yang Peng, et al. Microscopic pore structure characteristics of the upper member of Oligocene Xiaganchaigou Formation in Yingxi area, Qaidam Basin[J]. Lithologic Reservoirs, 2023, 35(1): 132-144. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202301012.htm [42] 宋明明, 韩淑乔, 董云鹏, 等. 致密砂岩储层微观水驱油效率及其主控因素[J]. 岩性油气藏, 2020, 32(1): 135-143. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202001015.htmSong Mingming, Han Shuqiao, Dong Yunpeng, et al. Microscopic water flooding efficiency and main controlling factors of tight sandstone reservoir[J]. Lithologic Reservoirs, 2020, 32(1): 135-143. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202001015.htm [43] 张文政, 王经玺. 基于显微CT的不同煤种微观孔隙结构综合表征[J]. 煤炭科学技术, 2021, 49(S2): 85-92. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ2021S2015.htmZhang Wenzheng, Wang Jingxi. Characterization of microscopic pore structure of different coal types based on micro CT[J]. Coal Science and Technology, 2021, 49(S2): 85-92. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ2021S2015.htm [44] 邢敏, 吴金随, 张辞源, 等. 基于CT扫描技术对煤岩的孔隙结构的提取和研究[J]. 华北科技学院学报, 2021, 18(3): 32-38. https://www.cnki.com.cn/Article/CJFDTOTAL-HBKJ202103006.htmXing Min, Wu Jinsui, Zhang Ciyuan, et al. Extraction and research on the pore structure of coal and rockbased on CT scanning technology[J]. Journal of North China Institute of Science and Technology, 2021, 18(3): 32-38. https://www.cnki.com.cn/Article/CJFDTOTAL-HBKJ202103006.htm [45] 李伟峰, 刘云, 于小龙, 等. 致密油储层岩石孔喉比与渗透率、孔隙度的关系[J]. 石油钻采工艺, 2017, 39(2): 125-129. https://www.cnki.com.cn/Article/CJFDTOTAL-SYZC201702002.htmLi Weifeng, Liu Yun, Yu Xiaolong, et al. Relationship of pore-throat ratio vs. permeability and porosity of tight oil reservoir rock[J]. Oil Drilling & Production Technology, 2017, 39(2): 125-129. https://www.cnki.com.cn/Article/CJFDTOTAL-SYZC201702002.htm [46] 何贤, 闫建平, 王敏, 等. 低渗透砂岩孔隙结构与采油产能关系: 以东营凹陷南坡F154区块为例[J]. 岩性油气藏, 2022, 34(1): 106-117. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202201010.htmHe Xian, Yan Jianping, Wang Min, et al. Relationship between pore structure and oil production capacity of low permeability sandstone: a case study of block F154 in south slope of Dongying Sag[J]. Lithologic Reservoirs, 2022, 34(1): 106-117. https://www.cnki.com.cn/Article/CJFDTOTAL-YANX202201010.htm [47] Ren D Z, Wang X Z, Kou Z H, et al. Feasibility evaluation of CO2 EOR and storage in tight oil reservoirs: a demonstration project in the Ordos Basin[J]. Fuel, 2023, 331: 125652. -

下载:

下载: