Study on the correlation of macro and meso parameters of parallel bond model sandstone

-

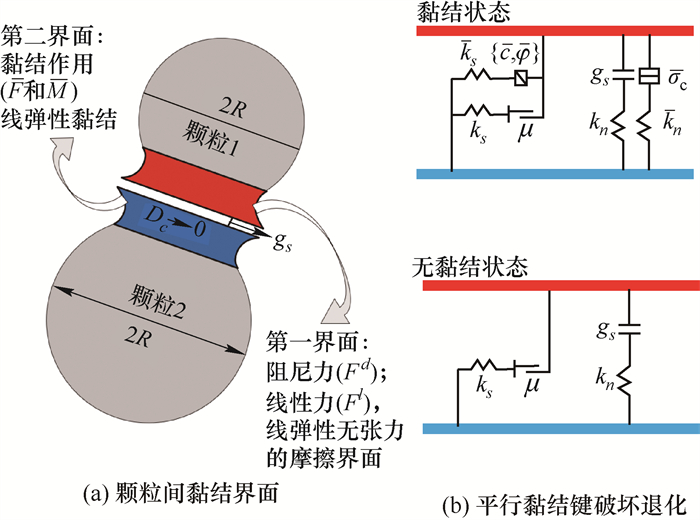

摘要: 为研究砂岩细观层面的力学响应及破坏特征,本文首先开展室内岩石压缩试验和基于平行黏结模型的PFC2D单轴宏细观参数关联性数值试验;然后采用试错法确定各细观参数对宏观力学指标的影响程度排序,并进行显著因子交互作用分析;最终利用回归分析建立宏细观参数间函数关系;运用控制变量法研究岩样裂纹演化及破坏形式的主要影响因素。研究结果表明:①单轴抗压强度σc与平行黏聚力c、黏结法向强度σc、黏结内摩擦角φ呈非线性关系;②弹性模量E与黏结模量E*、黏结刚度比k*呈多项式关系;③泊松比v与k*、摩擦系数μ呈线性关系;④抗拉强度σt与c、σc呈较好的线性关系;⑤岩样裂纹演化与破坏形式主要受黏结强度比σc/c影响,其与拉伸裂纹数目负相关,与剪切裂纹数目正相关;随σc/c增大,岩样的破坏形式呈拉伸破坏—共轭破坏—剪切破坏的变化特征。室内试验和数值模拟的单轴压缩σ-ε演化规律及破坏形式基本一致。Abstract: In order to study the mechanical response and failure characteristics of sandstone at the meso level, this paper first carried out indoor rock compression test and PFC2D uniaxial macro-meso parameter correlation numerical test based on parallel bond model.Then, the trial-and-error method is used to determine the order of the influence degree of each mesoscopic parameter on the macroscopic mechanical index, and the interaction analysis of significant factors is carried out.Finally, the regression analysis is used to establish the functional relationship between macroscopic and mesoscopic parameters.The main influencing factors of crack evolution and failure mode of rock samples are studied by using the control variable method.The results show that: ①The uniaxial compressive strength σc has a complex nonlinear relationship with parallel cohesion c, bond normal strength σc and bond internal friction angle φ.; ② Elastic modulus E has a polynomial relationship with bond modulus E * and bond stiffness ratio k *; ③ Poisson's ratio v is linear with k * and friction coefficient μ; ④The tensile strength σt has a good linear relationship with c and σc.; ⑤The crack evolution and failure mode of rock samples are mainly affected by the bond strength ratio σc/c, which is negatively correlated with the number of tensile cracks and positively correlated with the number of shear cracks. With σc/c increases, the failure mode of rock samples is characterized by tensile failure-conjugate failure-shear failure.The evolution law and failure form of uniaxial compression σ-ε in laboratory test and numerical simulation are basically the same.

-

表 1 PFC2D平行黏结模型主要宏细观参数表

Table 1. Main macro and micro parameters of PFC2D parallel bonding model

宏观参数 细观参数 平行黏结细观参数 颗粒细观参数 单轴抗压强度 σc/MPa 平行黏结法向强度 σc/MPa 颗粒摩擦系数 μ 抗拉强度 σt/MPa 平行黏结切向强度 τc/MPa 颗粒最小半径 Rmin/mm 弹性模量 E/GPa 平行黏结模量 E*/GPa 颗粒密度 ρ/(kg·m-3) 泊松比 v 平行黏结内摩擦角 φ/(°) 颗粒刚度比 k*=kn/ks 内摩擦角 φ/(°) 平行黏结力 c/MPa 颗粒半径比 Rmax/Rmin 平行黏结半径乘子 λ 颗粒接触模量 EC/GPa 平行黏结刚度比 k*=kn/ks 表 2 PFC2D平行黏结模型细观参数水平

Table 2. Level table of meso parameters of PFC2D parallel bonding model

细观参数 因子水平 1 2 3 4 5 σc/MPa 10 30 50 70 90 E*/GPa 10 20 30 40 50 φ/(°) 15 25 35 45 55 k*=kn/ks 1 2 3 4 5 c/MPa 15 30 45 60 75 μ 0.15 0.25 0.35 0.45 0.55 表 3 基于PFC2D平行黏结模型宏细观参数关系数值模拟结果

Table 3. Numerical simulation results of fine macro parameter relationship based on PFC2D parallel bonding model

试验编号 细观参数影响因素及因子水平取值 宏观参数模拟结果 σc/MPa E*/GPa φ/(°) k*=kn/ks c/MPa μ σc/MPa E/GPa v σt(σt/σc)/MPa 1 10 10 15 5 15 0.15 20.12 13.03 0.38 2.11 (0.104) 2 30 20 35 3 75 0.15 61.4 24.5 0.32 7.11 (0.115) 3 70 50 55 4 75 0.45 110.12 58.30 0.31 19.65 (0.178) 4 50 10 35 4 30 0.45 65.0 45.0 0.29 6.45 (0.100) $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ 46 50 30 15 4 30 0.35 70.70 34.80 0.33 6.29 (0.088) 47 10 20 35 1 30 0.55 20.00 31.50 0.06 3.85 (0.192) 48 90 10 35 4 60 0.45 125.87 12.18 0.31 25.21 (0.200) 表 4 PFC2D不同黏结强度比下数值单轴压缩岩石破坏形式

Table 4. Numerical uniaxial compression rock failure modes under different bond strength ratios of PFC2D

黏结强度比σc/c 0.25 0.5 0.75 1.0 1.33 1.66 2.0 2.3 2.7 3.0 3.5 4.0 破坏形式 张拉 张拉 张拉 张拉 张拉 共轭 共轭 共轭 共轭 共轭 剪切 剪切 表 5 平行黏结模型细观参数

Table 5. Microscopic parameter of parallel bond model

试验编号 σc/MPa E*/GPa φ/(°) k* c/MPa μ A1 35.5 9.47 15 3.2 76.85 0.55 B1 25.8 15.1 35 2.1 57.33 0.55 B2 18.8 4.40 35 2.5 30.55 0.50 C1 14.0 3.90 15 3.0 26.30 0.55 C2 36.1 5.20 25 3.0 68.30 0.52 C3 27.5 7.60 20 2.0 49.50 0.30 表 6 岩石的宏观力学参数试验值与模拟值对比

Table 6. Comparison between experimental and simulated values of macro mechanical parameters of rock

试验编号 数值模拟 室内试验 误差率/% σc/MPa E/GPa v σt(σt/σc) σc/MPa E/GPa v σt/MPa σc E v σt A1 98.98 17.43 0.19 7.11(0.071) 96.11 16.58 0.18 6.52 2.89 4.87 5.15 9.04 B1 68.53 11.55 0.18 6.12(0.089) 70.02 12.02 0.17 5.83 2.12 3.91 6.06 4.73 B2 33.43 8.84 0.19 4.95(0.148) 35.85 8.51 0.21 4.51 6.95 3.87 9.52 8.88 C1 23.41 4.61 0.20 2.27(0.096) 25.15 4.98 0.21 2.41 6.77 7.42 4.76 6.16 C2 74.72 9.91 0.24 6.83(0.091) 72.61 9.81 0.23 6.31 2.82 1.01 4.16 8.24 C3 60.23 15.9 0.18 4.89(0.081) 61.70 15.33 0.19 4.46 2.38 3.71 3.15 9.64 -

[1] Wu L Y, Wang Z, Ma D, et al. A continuous damage statistical constitutive model for sandstone and mudstone based on triaxial compression tests[J]. Rock Mechanics and Rock Engineering, 2022, 55: 4963-4978. doi: 10.1007/s00603-022-02924-6 [2] Wu L Y, Ma D, Wang Z F, et al. A deep CNN-based constitutive model for describing of statics characteristics of rock materials[J]. Engineering Fracture Mechanics, 2023, 279: 109054. doi: 10.1016/j.engfracmech.2023.109054 [3] Aydan Ö. Rock mechanics and rock engineering: volume 1: fundamentals of rock mechanics[M]. Florida: CRC Press, 2019. [4] 郝保钦, 张昌锁, 王晨龙, 等. 岩石PFC2D模型细观参数确定方法研究[J]. 煤炭科学技术, 2022, 50(4): 132-141. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202204013.htmHao Baoqin, Zhang Changsuo, Wang Chenlong, et al. Study on determination micro-parameters of rock PFC2D model[J]. Coal Science and Technology, 2022, 50(4): 132-141. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202204013.htm [5] 石崇, 张强, 王盛年. 颗粒流(PFC5.0)数值模拟技术及应用[J]. 岩土力学, 2018, 39(S2): 36. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2018S2005.htmShi Chong, Zhang Qiang, Wang Shengnian. Numerical simulation technology of particle flow (PFC5.0) and its application[J]. Rock and Soil Mechanics, 2018, 39(S2): 36. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2018S2005.htm [6] Cundall P, Strack O. Discussion: a discrete numerical model for granular assemblies[J]. Geotechnique, 1980, 30: 331-336. doi: 10.1680/geot.1980.30.3.331 [7] 李坤, 程谦恭, 林棋文, 等. 高速远程滑坡颗粒流研究进展[J]. 地球科学, 2022(3): 893-912. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX202203012.htmLi Kun, Cheng Qiangong, Lin Qiwen, et al. State of the art on rock avalanche dynamics from granular flow mechanics[J]. Earth Science, 2022(3): 893-912. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX202203012.htm [8] 胡训健, 卞康, 刘建, 等. 离散裂隙网络对岩石力学性质和声发射特性影响的颗粒流分析[J]. 岩土力学, 2022, 43(S1): 542-552. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2022S1054.htmHu Xunjian, Bian Kang, Liu Jian, et al. Particle flow code analysis of the effect of discrete fracture network on rock mechanical properties and acoustic emission characteristics[J]. Rock and Soil Mechanics, 2022, 43(S1): 542-552. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2022S1054.htm [9] Wei W J, Yang S L, Li M, et al. Motion mechanisms for top coal and gangue blocks in longwall top coal caving (LTCC) with an extra-thick seam[J]. Rock Mechanics and Rock Engineering, 2022, 55(8): 5107-5121. doi: 10.1007/s00603-022-02928-2 [10] 晏莉, 吕超慧, 喻少华, 等. 近邻双孔隧道围岩联合压力拱试验与数值分析[J]. 北京交通大学学报, 2022, 46(3): 103-109. https://www.cnki.com.cn/Article/CJFDTOTAL-BFJT202203012.htmYan Li, Lü Chaohui, Yu Shaohua, et al. Test and numerical analysis on combined pressure arch of surrounding rock in adjacent twin tunnels[J]. Journal of Beijing Jiaotong University, 2022, 46(3): 103-109. https://www.cnki.com.cn/Article/CJFDTOTAL-BFJT202203012.htm [11] 李涛, 朱连华, 李彬如, 等. 深基坑开挖土拱效应影响因素研究[J]. 中国矿业大学学报, 2017, 46(1): 58-65. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201701008.htmLi Tao, Zhu Lianhua, Li Binru, et al. Study of the influence factors of soal arching effect for deep founding pit excavation[J]. Journal of China University of Mining & Technology, 2017, 46(1): 58-65. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201701008.htm [12] 邓益兵, 杨彦骋, 史旦达, 等. 三维离散元大尺度模拟中变粒径方法的优化及其应用[J]. 岩土工程学报, 2017, 39(1): 62-70. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201701005.htmDeng Yibing, Yang Yancheng, Shi Danda, et al. Refinement and application of variable particle-sizemethodsin 3D discrete element modelling for large-scale problems[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(1): 62-70. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201701005.htm [13] Itasca Consulting Group lnc. PFC2D users manual (version 5.0)[R]. Minnesota: Itasca Consulting Group lnc., 2016. [14] 阿比尔的, 郑颖人, 冯夏庭, 等. 平行黏结模型宏细观力学参数相关性研究[J]. 岩土力学, 2018, 39(4): 1289-1301. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201804019.htmA Bierdi, Zheng Yingren, Feng Xiating, et al. Relationship between particle micro and macro mechanical parameters of parallel-bond model[J]. Rock and Soil Mechanics, 2018, 39(4): 1289-1301. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201804019.htm [15] Yang S Q, Yin P, Huang Y H. Experiment and discrete element modelling on strength, deformation and failure behaviour of shale under Brazilian compression[J]. Rock Mechanics and Rock Engineering, 2019, 52(7): 4339-4359. [16] 周喻, 吴顺川, 焦建津, 等. 基于BP神经网络的岩土体细观力学参数研究[J]. 岩土力学, 2011, 32(12)3821-3826. doi: 10.3969/j.issn.1000-7598.2011.12.045Zhou Yu, Wu Shunchuan, Jiao Jianjin, et al. Research on mesomechanical parameters of rock and soil mass based on BP neural network[J]. Rock and Soil Mechanics, 2011, 32(12)3821-3826. doi: 10.3969/j.issn.1000-7598.2011.12.045 [17] Yoon J. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation[J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(6): 871-889. doi: 10.1016/j.ijrmms.2007.01.004 [18] Xu Z H, Wang Z Y, Wang W Y, et al. An integrated parameter calibration method and sensitivity analysis of microparameters on mechanical behavior of transversely isotropic rocks[J]. Computers and Geotechnics, 2022, 142: 104573. doi: 10.1016/j.compgeo.2021.104573 [19] 陈鹏宇, 孔莹, 余宏明. 岩石单轴压缩PFC2D模型细观参数标定研究[J]. 地下空间与工程学报, 2018, 14(5): 1240-1249. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE201805013.htmChen Pengyu, Kong Ying, Yu Hongming. Research on the calibration method of microparameters of a uniaxial compression PFC2D model for rock[J]. Chinese Journal of Underground Space and Engineering, 2018, 14(5): 1240-1249. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE201805013.htm [20] 丛宇, 王在泉, 郑颖人, 等. 基于颗粒流原理的岩石类材料细观参数的试验研究[J]. 岩土工程学报, 2015(6): 1031-1040. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201506010.htmCong Yu, Wang Zaiquan, Zheng Yingren, et al. Experimental study on microscopic parameters of brittle materials based on particle flow theory[J]. Chinese Journal of Geotechnical Engineering, 2015(6): 1031-1040. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201506010.htm [21] Nardin A, Schrefler B A. Modelling of cutting tool-soil interaction-part Ⅱ: macromechanical model and upscaling[J]. Computational Mechanics, 2005, 36(5): 343-359. doi: 10.1007/s00466-005-0658-5 [22] 王一伟, 刘润, 孙若晗, 等. 基于抗转模型的颗粒材料宏-细观关系研究[J]. 岩土力学, 2022, 43(4): 945-956, 968. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202204009.htmWang Yiwei, Liu Run, Sun Ruohan, et al. Macroscopic and mesoscopic correlation of granular materials based on rolling resistance linear contact model[J]. Rock and Soil Mechanics, 2022, 43(4): 945-956, 968. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202204009.htm [23] 崔蓬勃, 朱永全, 刘勇, 等. 非饱和砂土隧道土拱效应模型试验及颗粒流数值模拟研究[J]. 岩土力学, 2021, 42(12): 3451-3466. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202112024.htmCui Pengbo, Zhu Yongquan, Liu Yong, et al. Model test and particle flow numerical simulation of soil arch effect for unsaturated sandy soil tunnel[J]. Rock and Soil Mechanics, 2021, 42(12): 3451-3466. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202112024.htm [24] 中华人民共和国住房和城乡建设部. 工程岩体试验方法标准: GB/T 50266-2013[S]. 北京: 中国计划出版社, 2013.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of engineering rock mass: GB/T 50266-2013[S]. Beijing: China Planning Press, 2013. [25] Potyondy D O, Cundall P A. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329-1364. doi: 10.1016/j.ijrmms.2004.09.011 [26] Dang Z H, Yin Z M, Wang D S, et al. Experimental study on the calibration of microparameters of dolomite in the barun open-pit mine on the basis of the parallel bond model[J]. Advances in Civil Engineering, 2021, 2021: 1-11. [27] 许明, 张永兴. 岩石力学[M]. 4版. 北京: 中国建筑工业出版社, 2020. [28] 苏承东, 付义胜. 红砂岩三轴压缩变形与强度特征的试验研究[J]. 岩石力学与工程学报, 2014, 33(S1): 3164-3169. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2014S1080.htmSu Chengdong, Fu Yisheng. Experimental study of triaxial compression deformation and strength characteristics of red sandstone[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(S1): 3164-3169. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2014S1080.htm [29] 周杰, 汪永雄, 周元辅. 基于颗粒流的砂岩三轴破裂演化宏-细观机理[J]. 煤炭学报, 2017, 42(S1): 76-82. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2017S1011.htmZhou Jie, Wang Yongxiong, Zhou Yuanfu. Macro-micro evolution mechanism on sandstone failure in triaxial compression test based on PFC. 2d[J]. Journal of China Coal Society, 2017, 42(S1): 76-82. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2017S1011.htm [30] 刘相如, 杨圣奇. 基于正交试验的岩石细观力学参数数值研究[J]. 应用基础与工程科学学报, 2018, 26(4): 918-928. https://www.cnki.com.cn/Article/CJFDTOTAL-YJGX201804020.htmLiu Xiangru, Yang Shengqi. Research on mesomechanical parameters of rock specimens based on orthogonal numerical tests[J]. Journal of Basic Science and Engineering, 2018, 26(4): 918-928. https://www.cnki.com.cn/Article/CJFDTOTAL-YJGX201804020.htm [31] 王朝阳, 林鹏, 许振浩, 等. 横观各向同性岩体平直光滑节理双模型细观参数联合标定方法[J]. 中南大学学报: 自然科学版, 2022, 53(6): 2211-2223. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD202206022.htmWang Zhaoyang, Lin Peng, Xu Zhenhao, et al. A transversely isotropic rocks integrated microparameter calibration method for flat joint model and smooth joint model[J]. Journal of Central South University: Science and Technology, 2022, 53(6): 2211-2223. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD202206022.htm [32] 徐金明, 谢芝蕾, 贾海涛. 石灰岩细观力学特性的颗粒流模拟[J]. 岩土力学, 2010, 31(S2): 390-395. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2010S2070.htmXu Jinming, Xie Zhilei, Jia Haitao. Simulation of mesomechanical properties of limestone using particle flow code[J]. Rock and Soil Mechanics, 2010, 31(S2): 390-395. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2010S2070.htm -

下载:

下载: