Study on microbial cemented backfill mining technology

-

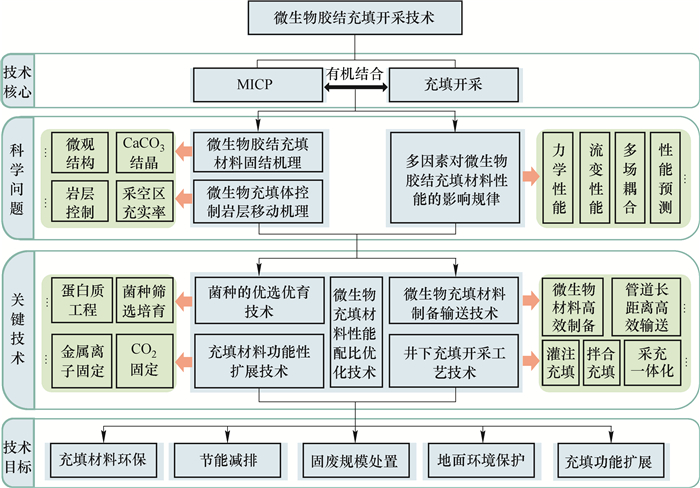

摘要: 针对当前充填开采技术中水泥基胶结料存在的高排放和高耗能问题,将微生物诱导CaCO3沉积(MICP)技术引入充填开采领域,研究了微生物胶结充填材料的力学性能,建立了基于MICP的微生物胶结充填开采技术体系。研究表明,拌和型和灌注型微生物胶结充填材料的强度随着营养液浓度和菌液用量的增加呈现先增大后减小的规律,平均强度分别为0.88 MPa和17.95 MPa;微生物充填材料内部的有效CaCO3晶体是充填材料固结的关键,在拌和型试样中以方解石和球霰石的矿物形式存在,在灌注型试样中主要为方解石。微生物胶结充填开采技术的节能减排环境效益显著,特别是在当前环保需求和政策背景下,该技术具有科学价值和发展前景。

-

关键词:

- 微生物诱导碳酸钙沉积 /

- 微生物充填材料 /

- 充填开采 /

- 绿色开采

Abstract: The microbial induced carbonate precipitation(MICP) technology is proposed in the field of backfill mining to tackle high emission and high energy consumption in the current backfill system.Specifically, mechanical properties of microbial cemented backfill materials are investigated, and a proposal of microbial cemented backfill mining technology is presented in this paper.Results show that the strength of mixed and grouted microbial cemented backfill first increases and then decreases with the increase of cementation solution concentration and bacterial solution dosage.The average strength is 0.88 MPa and 17.95 MPa respectively.The effective CaCO3 crystal in the microbial backfill material is the key to its consolidation.The CaCO3 crystal of the mixing sample exists in the form of calcite and vaterite, and mainly calcite in the grouted sample.Microbial cemented backfill mining technology has significant environmental benefits such as energy conservation and emission reduction.There is happy prospect for this technology under current environmental needs and policies. -

表 1 各胶结材料单价

Table 1. Unit price of cementing materials

元/t 粉煤灰 水泥 添加剂 氯化钙 70 500 300 1 620 尿素 硫酸铵 酵母提取物 氢氧化钠 2 525 1 400 1 200 4 000 -

[1] 张吉雄, 张强, 巨峰, 等. 煤矿"采选充+X"绿色化开采技术体系与工程实践[J]. 煤炭学报, 2019, 44(1): 64-73. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201901007.htmZhang Jixiong, Zhang Qiang, Ju Feng, et al. Practice and technique of green mining with integration of mining, dressing, backfilling and X in coal resources[J]. Journal of China Coal Society, 2019, 44(1): 64-73. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201901007.htm [2] 邓雪杰. 特厚煤层上向分层长壁逐巷胶结充填开采覆岩移动控制机理研究[D]. 徐州: 中国矿业大学, 2017: 19-25. [3] 邓雪杰, 张吉雄, 周楠, 等. 特厚煤层长壁巷式胶结充填开采技术研究与应用[J]. 采矿与安全工程学报, 2014, 31(6): 857-862. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201406005.htmDeng Xuejie, Zhang Jixiong, Zhou Nan, et al. The research and application of longwall-roadway cemented backfilling mining technology in extra-thick coal seam[J]. Journal of Mining & Safety Engineering, 2014, 31(6): 857-862. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201406005.htm [4] 宋光远, 周华强. 膏体充填回收条带煤柱覆岩活化规律研究[J]. 煤矿安全, 2019, 50(2): 228-231. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201902053.htmSong Guangyuan, Zhou Huaqiang. Study on activation laws of overlying strata during strip coal pillar recovery by paste backfill[J]. Safety in Coal Mines, 2019, 50(2): 228-231. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201902053.htm [5] 杨宝贵, 杨捷, 于跃, 等. 煤矿新型胶凝充填材料配比试验及水化机理研究[J]. 矿业科学学报, 2017, 2(5): 475-481. http://kykxxb.cumtb.edu.cn/article/id/98Yang Baogui, Yang Jie, Yu Yue, et al. Study on proportioning test of a new cementing filling material and hydration mechanism[J]. Journal of Mining Science and Technology, 2017, 2(5): 475-481. http://kykxxb.cumtb.edu.cn/article/id/98 [6] 吴爱祥, 李红, 程海勇, 等. 全尾砂膏体流变学研究现状与展望(上): 概念、特性与模型[J]. 工程科学学报, 2020, 42(7): 803-813. https://d.wanfangdata.com.cn/periodical/bjkjdxxb202007001Wu Aixiang, Li Hong, Cheng Haiyong, et al. Status and prospects of researches on rheology of paste backfill using unclassified tailings(Part 1): concepts, characteristics and models[J]. Chinese Journal of Engineering, 2020, 42(7): 803-813. https://d.wanfangdata.com.cn/periodical/bjkjdxxb202007001 [7] 吴爱祥, 李红, 程海勇, 等. 全尾砂膏体流变学研究现状与展望(下): 流变测量与展望[J]. 工程科学学报, 2021, 43(4): 451-459. https://www.zhangqiaokeyan.com/academic-journal-cn_journal-beijing-university-science-technology_thesis/0201288420364.htmlWu Aixiang, Li Hong, Cheng Haiyong, et al. Status and prospects of research on the rheology of paste backfill using unclassified tailings(Part 2): rheological measurement and prospects[J]. Chinese Journal of Engineering, 2021, 43(4): 451-459. https://www.zhangqiaokeyan.com/academic-journal-cn_journal-beijing-university-science-technology_thesis/0201288420364.html [8] 周旭, 阮竹恩, 吴爱祥, 等. 基于FBRM和PVM技术的尾矿浓密过程絮团演化规律[J]. 工程科学学报, 2021, 43(11): 1425-1432. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202111001.htmZhou Xu, Ruan Zhuen, Wu Aixiang, et al. Aggregate evolution rule during tailings thickening based on FBRM and PVM[J]. Chinese Journal of Engineering, 2021, 43(11): 1425-1432. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202111001.htm [9] 姜关照, 吴爱祥, 王贻明. 碱激发水泥-磷渣固化性能及与含硫尾砂的相容性[J]. 工程科学学报, 2020, 42(8): 963-971. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202008003.htmJiang Guanzhao, Wu Aixiang, Wang Yiming. Curing performance of alkali-activated cement-phosphorous slag and its compatibility with sulfur tailings[J]. Chinese Journal of Engineering, 2020, 42(8): 963-971. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202008003.htm [10] 阮竹恩, 吴爱祥, 王贻明, 等. 絮凝沉降对浓缩超细尾砂料浆屈服应力的影响[J]. 工程科学学报, 2021, 43(10): 1276-1282. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202110002.htmRuan Zhuen, Wu Aixiang, Wang Yiming, et al. Effect of flocculation sedimentation on the yield stress of thickened ultrafine tailings slurry[J]. Chinese Journal of Engineering, 2021, 43(10): 1276-1282. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202110002.htm [11] 温震江, 高谦, 杨志强, 等. 金川镍渣充填胶凝材料力学性能与水化机理[J]. 中国有色金属学报, 2021, 31(4): 1074-1083. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ202104024.htmWen Zhenjiang, Gao Qian, Yang Zhiqiang, et al. Mechanical properties and hydration mechanism of Jinchuan nickel slag filling cementitious material[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(4): 1074-1083. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ202104024.htm [12] 温震江, 高谦, 王永定, 等. 基于熵权多属性决策的充填胶凝材料开发及料浆配比优化[J]. 湖南大学学报: 自然科学版, 2021, 48(6): 8-16. https://www.cnki.com.cn/Article/CJFDTOTAL-HNDX202106002.htmWen Zhenjiang, Gao Qian, Wang Yongding, et al. Development of filling cementitious material and optimization of slurry proportion based on entropy weight multi-attribute decision[J]. Journal of Hunan University: Natural Sciences, 2021, 48(6): 8-16. https://www.cnki.com.cn/Article/CJFDTOTAL-HNDX202106002.htm [13] 韦寒波, 巴蕾, 高谦. 粉煤灰掺量对胶结充填体强度影响规律研究[J]. 矿业研究与开发, 2020, 40(12): 28-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK202012007.htmWei Hanbo, Ba Lei, Gao Qian. Study on the influence law of fly ash content on the strength of cemented backfill[J]. Mining Research and Development, 2020, 40(12): 28-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK202012007.htm [14] 吴凡, 杨发光, 肖柏林, 等. 钢渣掺量对膏体早期强度及流变特性的影响[J]. 材料导报, 2021, 35(3): 3021-3025. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202103004.htmWu Fan, Yang Faguang, Xiao Bolin, et al. Influence of steel slag dosage on early age strength and rheological properties of paste[J]. Materials Reports, 2021, 35(3): 3021-3025. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202103004.htm [15] Deng X J, Li Y, Liu H, et al. Examining energy consumption and carbon emissions of microbial induced carbonate precipitation using the life cycle assessment method[J]. Sustainability, 2021, 13(9): 4856. doi: 10.3390/su13094856 [16] Su X, Zhang X. A detailed analysis of the embodied energy and carbon emissions of steel-construction residential buildings in China[J]. Energy and Buildings, 2016, 119: 323-330. doi: 10.1016/j.enbuild.2016.03.070 [17] Guo S J, Zhang J X, Li M, et al. A preliminary study of solid-waste coal gangue based biomineralization as eco-friendly underground backfill material: material preparation and macro-micro analyses[J]. Science of the Total Environment, 2021, 770: 145241. doi: 10.1016/j.scitotenv.2021.145241 [18] Xu X C, Guo H X, Cheng X H, et al. The promotion of magnesium ions on aragonite precipitation in MICP process[J]. Construction and Building Materials, 2020, 263: 120057. doi: 10.1016/j.conbuildmat.2020.120057 [19] Mutitu K D, Munyao M O, Wachira M J, et al. Effects of biocementation on some properties of cement-based materials incorporating Bacillus Species bacteria-a review[J]. Journal of Sustainable Cement-Based Materials, 2019, 8(5): 309-325. doi: 10.1080/21650373.2019.1640141 [20] Mondal S, (Dey)Ghosh A. Review on microbial induced calcite precipitation mechanisms leading to bacterial selection for microbial concrete[J]. Construction and Building Materials, 2019, 225: 67-75. doi: 10.1016/j.conbuildmat.2019.07.122 [21] Al-Salloum Y, Hadi S, Abbas H, et al. Bio-induction and bioremediation of cementitious composites using microbial mineral precipitation-a review[J]. Construction and Building Materials, 2017, 154: 857-876. doi: 10.1016/j.conbuildmat.2017.07.203 [22] Mujah D, Shahin M A, Cheng L. State-of-the-art review of biocementation by microbially induced calcite precipitation(MICP)for soil stabilization[J]. Geomicrobiology Journal, 2017, 34(6): 524-537. doi: 10.1080/01490451.2016.1225866 [23] Manzur T, Rahman F, Afroz S, et al. Potential of a microbiologically induced calcite precipitation process for durability enhancement of masonry aggregate concrete[J]. Journal of Materials in Civil Engineering, 2017, 29(5): 04016290. doi: 10.1061/(ASCE)MT.1943-5533.0001799 [24] Song H W, Kumar A, Ding Y, et al. Removal of Cd2+ from wastewater by microorganism induced carbonate precipitation(MICP): an economic bioremediation approach[J]. Separation and Purification Technology, 2022, 297: 121540. doi: 10.1016/j.seppur.2022.121540 [25] Zeng Y, Chen Z Z, Lyu Q Y, et al. Microbiologically induced calcite precipitation for in situ stabilization of heavy metals contributes to land application of sewage sludge[J]. Journal of Hazardous Materials, 2023, 441: 129866. doi: 10.1016/j.jhazmat.2022.129866 [26] 谭谦. 微生物用于石质文物破损修复的试验研究[D]. 北京: 清华大学, 2017: 71-88. [27] 李萌, 由士权, 康绍斌, 等. 砂土中混凝土裂缝的微生物封堵试验研究[J]. 清华大学学报: 自然科学版, 2019, 59(8): 614-618. https://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201908004.htmLi Meng, You Shiquan, Kang Shaobin, et al. Experimental study of microbial clogging of concrete cracks in sand[J]. Journal of Tsinghua University: Science and Technology, 2019, 59(8): 614-618. https://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201908004.htm [28] Qian C X, Yu X N, Wang X. Potential uses and cementing mechanism of bio-carbonate cement and bio-phosphate cement[J]. AIP Advances, 2018, 8(9): 095224. doi: 10.1063/1.5040730 [29] Zheng T W, Qian C X. Self-healing of later-age cracks in cement-based materials by encapsulation-based bacteria[J]. Journal of Materials in Civil Engineering, 2020, 32(11): 04020341. doi: 10.1061/(ASCE)MT.1943-5533.0003437 [30] Zheng T W, Su Y L, Qian C X, et al. Low alkali sulpho-aluminate cement encapsulated microbial spores for self-healing cement-based materials[J]. Biochemical Engineering Journal, 2020, 163: 107756. doi: 10.1016/j.bej.2020.107756 [31] Khan M N H, Amarakoon G G N N, Shimazaki S, et al. Coral sand solidification test based on microbially induced carbonate precipitation using ureolytic bacteria[J]. Materials Transactions, 2015, 56(10): 1725-1732. doi: 10.2320/matertrans.M-M2015820 [32] Al-Salloum Y, Abbas H, Sheikh Q I, et al. Effect of some biotic factors on microbially-induced calcite precipitation in cement mortar[J]. Saudi Journal of Biological Sciences, 2017, 24(2): 286-294. doi: 10.1016/j.sjbs.2016.01.016 [33] Deng X J, Yuan Z X, Li Y, et al. Experimental study on the mechanical properties of microbial mixed backfill[J]. Construction and Building Materials, 2020, 265: 120643. doi: 10.1016/j.conbuildmat.2020.120643 [34] Cavallo E, Nobile M, Cerrutti P, et al. Exploring the production of citric acid with Yarrowia lipolytica using corn wet milling products as alternative low-cost fermentation media[J]. Biochemical Engineering Journal, 2020, 155: 107463. doi: 10.1016/j.bej.2019.107463 [35] Zúñiga-Barra H, Toledo-Alarcón J, Torres-Aravena á, et al. Improving the sustainable management of mining tailings through microbially induced calcite precipitation: a review[J]. Minerals Engineering, 2022, 189: 107855. doi: 10.1016/j.mineng.2022.107855 [36] Lee Y S, Park W. Current challenges and future directions for bacterial self-healing concrete[J]. Applied Microbiology and Biotechnology, 2018, 102(7): 3059-3070. doi: 10.1007/s00253-018-8830-y [37] Filet A, Gadret J P, Loygue M, et al. Biocalcis and its applications for the consolidation of sands[C]// Proceedings of the Fourth International Conference on Grouting and Deep Mixing. February 15-18, 2012, New Orleans, Louisiana, USA. Reston, VA, USA: American Society of Civil Engineers, 2012: 1767-1780. [38] Zhao Q, Li L, Li C, et al. Factors affecting improvement of engineering properties of MICP-treated soil catalyzed by bacteria and urease[J]. Journal of Materials in Civil Engineering, 2014, 26(12): 04014094. doi: 10.1061/(ASCE)MT.1943-5533.0001013 [39] Deng X J, Li Y, Wang F, et al. Experimental study on the mechanical properties and consolidation mechanism of microbial grouted backfill[J]. International Journal of Mining Science and Technology, 2022, 32(2): 271-282. doi: 10.1016/j.ijmst.2022.01.010 [40] Cunningham A B, Phillips A J, Troyer E, et al. Wellbore leakage mitigation using engineered biomineralization[J]. Energy Procedia, 2014, 63: 4612-4619. doi: 10.1016/j.egypro.2014.11.494 [41] Achal V, Mukherjee A, Kumari D, et al. Biomineralization for sustainable construction-a review of processes and applications[J]. Earth-Science Reviews, 2015, 148: 1-17. doi: 10.1016/j.earscirev.2015.05.008 [42] Pacheco Torgal F, Labrincha J A. Biotechnologies and biomimetics for civil engineering[M]. Switzerland: Springer International Publishing, 2015. [43] Rahman M M, Hora R N, Ahenkorah I, et al. State-of-the-art review of microbial-induced calcite precipitation and its sustainability in engineering applications[J]. Sustainability, 2020, 12(15): 6281. doi: 10.3390/su12156281 [44] Dejong J T, Soga K, Kavazanjian E, et al. Biogeochemical processes and geotechnical applications: progress, opportunities and challenges[J]. Geotechnique, 2013, 63(4): 287-301. doi: 10.1680/geot.SIP13.P.017 [45] 段宇, 徐国宾, 杨德锋, 等. MICP矿化产物中钙离子利用率的影响因素及微观物相分析[J]. 化工进展, 2019, 38(5): 2306-2313. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201905028.htmDuan Yu, Xu Guobin, Yang Defeng, et al. Influencing factors of calcium ion utilization in MICP mineralized products and analysis of microscopic image[J]. Chemical Industry and Engineering Progress, 2019, 38(5): 2306-2313. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201905028.htm [46] 李成杰, 魏桃员, 季斌, 等. 不同钙源及Ca2+浓度对MICP的影响[J]. 环境科学与技术, 2018, 41(3): 30-34. https://www.cnki.com.cn/Article/CJFDTOTAL-FJKS201803006.htmLi Chengjie, Wei Taoyuan, Ji Bin, et al. Study on MICP affected by different calcium sources and Ca2+ concentrations[J]. Environmental Science & Technology, 2018, 41(3): 30-34. https://www.cnki.com.cn/Article/CJFDTOTAL-FJKS201803006.htm [47] Wen K J, Li Y, Amini F, et al. Impact of bacteria and urease concentration on precipitation kinetics and crystal morphology of calcium carbonate[J]. Acta Geotechnica, 2020, 15(1): 17-27. doi: 10.1007/s11440-019-00899-3 [48] 程瑶佳, 唐朝生, 刘博, 等. 基于石灰石粉钙源的微生物固化砂土试验研究[J]. 高校地质学报, 2021, 27(6): 746-753. https://www.cnki.com.cn/Article/CJFDTOTAL-GXDX202106013.htmCheng Yaojia, Tang Chaosheng, Liu Bo, et al. Experimental sthdy on microbial solidified sand based on calcium source extracted from limestone powder[J]. Geological Journal of China Universities, 2021, 27(6): 746-753. https://www.cnki.com.cn/Article/CJFDTOTAL-GXDX202106013.htm [49] 王维大, 秦思远, 肖宇, 等. 不同钙源对MICP固化氰化尾渣的影响[J]. 有色金属: 冶炼部分, 2022(7): 131-137, 149. https://www.cnki.com.cn/Article/CJFDTOTAL-METE202207021.htmWang Weida, Qin Siyuan, Xiao Yu, et al. Effects of different calcium sources on MICP cured cyanidation tailings[J]. Nonferrous Metals: Extractive Metallurgy, 2022(7): 131-137, 149. https://www.cnki.com.cn/Article/CJFDTOTAL-METE202207021.htm [50] 张吉雄, 巨峰, 李猛, 等. 煤矿矸石井下分选协同原位充填开采方法[J]. 煤炭学报, 2020, 45(1): 131-140. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202001014.htmZhang Jixiong, Ju Feng, Li Meng, et al. Method of coal gangue separation and coordinated in situ backfill mining[J]. Journal of China Coal Society, 2020, 45(1): 131-140. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202001014.htm [51] 吴爱祥, 杨莹, 程海勇, 等. 中国膏体技术发展现状与趋势[J]. 工程科学学报, 2018, 40(5): 517-525. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201805001.htmWu Aixiang, Yang Ying, Cheng Haiyong, et al. Status and prospects of paste technology in China[J]. Chinese Journal of Engineering, 2018, 40(5): 517-525. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201805001.htm [52] 孙希奎, 赵庆民, 施现院. 条带残留煤柱膏体充填综采技术研究与应用[J]. 采矿与安全工程学报, 2017, 34(4): 650-654. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201704007.htmSun Xikui, Zhao Qingmin, Shi Xianyuan. Research and application on the technology of paste backfilling fully mechanized in residual strip pillar[J]. Journal of Mining & Safety Engineering, 2017, 34(4): 650-654. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201704007.htm [53] 白二虎, 郭文兵, 谭毅, 等. "条采留巷充填法"绿色协调开采技术[J]. 煤炭学报, 2018, 43(S1): 21-27. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2018S1003.htmBai Erhu, Guo Wenbing, Tan Yi, et al. Green coordinated mining technology of strip mining roadway backfilling method[J]. Journal of China Coal Society, 2018, 43(S1): 21-27. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2018S1003.htm [54] 胡炳南, 刘鹏亮, 崔锋, 等. 我国充填采煤技术回顾及发展现状[J]. 煤炭科学技术, 2020, 48(9): 39-47. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202009004.htmHu Bingnan, Liu Pengliang, Cui Feng, et al. Review and development status of backfill coal mining technology in China[J]. Coal Science and Technology, 2020, 48(9): 39-47. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202009004.htm [55] Xu X C, Guo H X, Li M, et al. Bio-cementation improvement via CaCO3 cementation pattern and crystal polymorph: a review[J]. Construction and Building Materials, 2021, 297: 123478. doi: 10.1016/j.conbuildmat.2021.123478 [56] Basaran Bundur Z, Kirisits M J, Ferron R D. Biomineralized cement-based materials: impact of inoculating vegetative bacterial cells on hydration and strength[J]. Cement and Concrete Research, 2015, 67: 237-245. doi: 10.1016/j.cemconres.2014.10.002 [57] Qiu J P, Xiang J C, Zhang W Q, et al. Effect of microbial-cemented on mechanical properties of iron tailings backfill and its mechanism analysis[J]. Construction and Building Materials, 2022, 318: 126001. doi: 10.1016/j.conbuildmat.2021.126001 [58] Lu H J, Qi C C, Chen Q S, et al. A new procedure for recycling waste tailings as cemented paste backfill to underground stopes and open pits[J]. Journal of Cleaner Production, 2018, 188: 601-612. doi: 10.1016/j.jclepro.2018.04.041 [59] Lu H J, Qi C C, Li C H, et al. A light barricade for tailings recycling as cemented paste backfill[J]. Journal of Cleaner Production, 2020, 247: 119388. doi: 10.1016/j.jclepro.2019.119388 -

下载:

下载: