Research on the influence of steel fiber content on the axial compressive behavior of self-compacting concrete-filled steel tubular columns

-

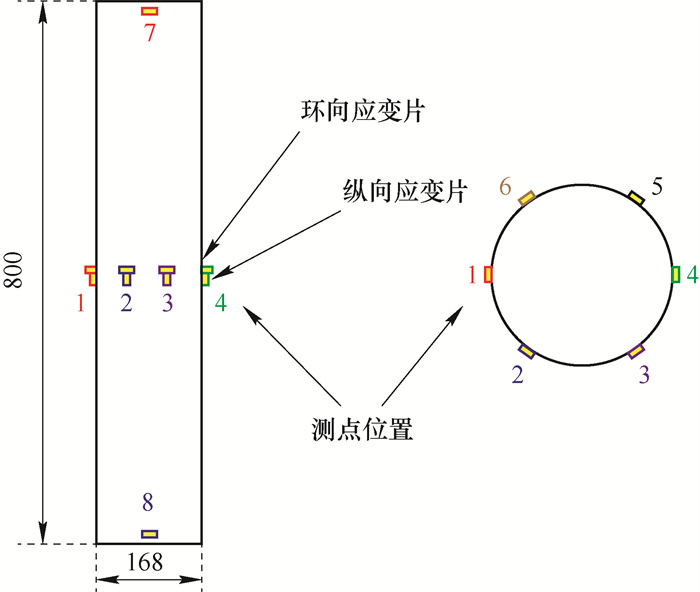

摘要: 为提高钢管混凝土柱轴压承载力,在自密实混凝土中掺入钢纤维,研究不同钢纤维掺量对自密实钢管混凝土柱轴压力学性能的影响。通过设计正交试验,研究3组钢纤维掺量对自密实混凝土强度的影响,并为钢管混凝土钢纤维用量提供依据;对钢纤维组、普通组自密实钢管混凝土柱进行轴压试验,研究钢纤维对自密实钢管混凝土柱轴压力学性能影响;基于ABAQUS建立26组不同钢纤维掺量钢管混凝土柱模型,根据现场试验结果验证模型的正确性,分析其中6组钢纤维掺量对其轴压性能的影响,并建立不同钢纤维掺量下钢管混凝土柱轴压承载力计算公式。结果表明,2 % 掺量钢纤维对自密实混凝土强度增长的贡献较为显著,并能提高约4 % 自密实钢管混凝土柱轴压承载力,为最适宜掺量。提出考虑钢纤维掺量对钢管混凝土强度提高的计算式,与试验结果吻合良好。

-

关键词:

- 钢纤维 /

- 自密实钢管混凝土柱 /

- 正交试验 /

- 轴心受压试验 /

- ABAQUS数值模拟

Abstract: In order to improve the axial compression bearing capacity of concrete filled steel tubular columns, steel fibers were added into self-compacting concrete.Through orthogonal test, the influence of 3 groups of steel fiber content on the strength of self-compacting concrete is studied, and the basis for the steel fiber content of concrete filled steel tube is provided.The axial compression tests of steel fiber reinforced concrete filled steel tubular columns and ordinary steel fiber reinforced concrete filled steel tubular columns were carried out to study the influence of steel fiber on the axial compression properties of self-compacting concrete filled steel tubular columns.Based on ABAQUS, 26 groups of concrete-filled steel tubular column models with different steel fiber content are established.After the correctness of the model is verified according to the field test results, the influence of six groups of steel fiber content on its axial compression performance is analyzed, and the calculation formula of the axial compression bearing capacity of concrete-filled steel tubular column with different steel fiber content is established.The results show that 2 % steel fiber has a significant contribution to the strength growth of self-compacting concrete, and can increase the axial compression bearing capacity of self-compacting concrete filled steel tubular columns by about 4 %.The calculation formula considering the increase of steel fiber content to the strength of concrete filled steel tube is proposed, which is in good agreement with the test results. -

表 1 核心混凝土材料用量

Table 1. Core concrete mix proportion design

kg 编号 超细粉煤灰 钢纤维 膨胀剂 水泥 水 砂 碎石 减水剂 C-1 51.20 78.50 30.72 460.80 193.00 737.00 832.00 4.10 C-2 102.40 118.00 35.84 409.60 193.00 737.00 832.00 4.10 C-3 153.60 157.00 40.96 358.40 193.00 737.00 832.00 4.10 C-4 102.40 118.00 40.96 409.60 193.00 737.00 832.00 4.10 C-5 153.60 157.00 35.84 358.40 193.00 737.00 832.00 4.10 C-6 51.20 78.50 30.72 409.60 193.00 737.00 832.00 4.10 C-7 153.60 157.00 35.84 358.40 193.00 737.00 832.00 4.10 C-8 51.20 79.00 30.72 460.80 193.00 737.00 832.00 4.10 C-9 102.40 118.00 40.96 409.60 193.00 737.00 832.00 4.10 表 2 正交试验结果

Table 2. Table of orthogonal test results

编号 各因素水平 28 d强度/MPa A超细粉煤灰 B钢纤维 C膨胀剂 D空白列 C-1 1(10.0) 1(1.0) 1(6.0) 1 66.3 C-2 1(10.0) 2(1.5) 2(7.0) 2 68.2 C-3 1(10.0) 3(2.0) 3(8.0) 3 72.1 C-4 2(20.0) 1(1.0) 3(8.0) 3 68.4 C-5 2(20.0) 2(1.5) 2(7.0) 1 69.7 C-6 2(20.0) 3(2.0) 1(6.0) 2 71.4 C-7 3(30.0) 1(1.0) 2(7.0) 2 64.9 C-8 3(30.0) 2(1.5) 1(6.0) 3 65.5 C-9 3(30.0) 3(2.0) 3(8.0) 1 68.3 注:括号内数值为配比,单位为%。 表 3 正交试验极差分析

Table 3. Range analysis of orthogonal test

MPa 参数 各因素28 d抗压强度 A超细粉煤灰 B钢纤维 C膨胀剂 K1 206.60 199.60 203.20 K2 209.50 203.40 206.70 K3 198.70 211.80 204.90 k1 68.87 66.53 67.73 k2 69.83 67.80 68.90 k3 66.23 70.60 68.30 R 3.60 4.07 1.17 水平数量 3 3 3 重复数r 3 3 3 最佳水平 2 3 2 主次顺序 B>A>C 注:响应值Kn为某因素n水平时试验数据求和;kn值为对应的Kn值平均值;最佳水平为某因子时最佳kn值对应的水平编号n;R值为因素的极差值,即某因素k最大值减去k最小值。 表 4 正交试验方差分析

Table 4. Analysis of variance of orthogonal test

考核指标 方差来源 偏差平方和 自由度 均方 F值 p值 28 d强度 A 20.829 2 10.414 36.189 0.027* B 25.982 2 12.991 45.143 0.022* C 2.042 2 1.021 3.548 0.220 截距 41 997.671 1 41 997.671 145 937.850 0.000** 残差 0.576 2 0.288 R2=0.988 注:F值用来评估组间差异,表示整个拟合方程的显著性,F越大,表示方程越显著,拟合程度越好;p值为衡量控制组与实验组差异的指标;*代表p < 0.05,表示两组存在显著差异;**代表p < 0.01,表示两组的差异极其显著。 表 5 钢管混凝土配合比设计

Table 5. Mix proportion design of concrete filled steel tubular under compression

kg 分组 钢纤维 粉煤灰 膨胀剂 水泥 水 砂 碎石 减水剂 钢纤维组 158.00 102.40 35.84 409.60 193.00 737.00 832.00 4.10 普通组 — 102.40 35.84 409.60 193.00 737.00 832.00 4.10 表 6 不同掺量钢纤维下试件极限荷载

Table 6. Ultimate load of specimens with different amount of steel fiber

钢纤维掺量/% 0 0.5 1.0 1.5 2.0 2.5 极限荷载/kN 1 191 1 229 1 275 1 324 1 351 1 334 -

[1] Xie Heping. Research framework and anticipatedresults of deep rock mechanics and mining theory[J]. Advanced Engineering Sciences, 2017(2): 1-16. [2] Zareifard M R, Fahimifar A. Analytical solutions for the stresses and deformations of deep tunnels in an elastic-brittle-plastic rock mass considering the damaged zone[J]. Tunnelling and Underground Space Technology, 2016, 58: 186-196. doi: 10.1016/j.tust.2016.05.007 [3] Shreedharan S, Kulatilake P H S W. Discontinuum equivalent continuum analysis of the stability of tunnels in a deep coal mine using the distinct element method[J]. Rock Mechanics and Rock Engineering, 2016, 49(5): 1903-1922. doi: 10.1007/s00603-015-0885-9 [4] Walton G, Diederichs M, Punkkinen A, et al. Back analysis of a pillar monitoring experiment at 2.4 km depth in the Sudbury Basin, Canada[J]. International Journal of Rock Mechanics and Mining Sciences, 2016, 85: 33-51. doi: 10.1016/j.ijrmms.2016.03.001 [5] 何满潮. 深部煤矿灾害机理及监测研究进展[J]. 煤炭科技, 2007(1): 1-5. doi: 10.19896/j.cnki.mtkj.2007.01.001He Manchao. Research progress on mechani-sm and monitoring of deep coal mine disasters[J]. Coal Science & Technology Magazine, 2007(1): 1-5. doi: 10.19896/j.cnki.mtkj.2007.01.001 [6] 潘一山, 李忠华, 章梦涛. 我国冲击地压分布、类型、机理及防治研究[J]. 岩石力学与工程学报, 2003, 22(11): 1844-1851. doi: 10.3321/j.issn:1000-6915.2003.11.019Pan Yishan, Li Zhonghua, Zhang Mengtao. Distribution, type, mechanism and prevention of rockbrust in China[J]. Chinese Journal of Rock Mechanics and Engineering, 2003, 22(11): 1844-1851. doi: 10.3321/j.issn:1000-6915.2003.11.019 [7] 姜耀东, 潘一山, 姜福兴, 等. 我国煤炭开采中的冲击地压机理和防治[J]. 煤炭学报, 2014, 39(2): 205-213. doi: 10.13225/j.cnki.jccs.2013.0024Jiang Yaodong, Pan Yishan, Jiang Fuxing, et al. State of the art review on mechanism and prevention of coal bumps in China[J]. Journal of China Coal Society, 2014, 39(2): 205-213. doi: 10.13225/j.cnki.jccs.2013.0024 [8] 吴科如, 张雄. 土木工程材料[M]. 上海: 同济大学出版社, 2003. [9] Ouyang Y, Zeng J J, Li L G, et al. Influence of concrete mix proportions on axial performance of concrete-filled steel tubes made with self-compacting concrete[J]. Advances in Structural Engineering, 2020, 23(5): 835-846. doi: 10.1177/1369433219884457 [10] 斯方海, 陈社生, 韩大富, 等. C60钢管自密实混凝土的配制及早期收缩性能研究[J]. 混凝土与水泥制品, 2017(1): 22-25, 30. doi: 10.3969/j.issn.1000-4637.2017.01.005Si Fanghai, Chen Shesheng, Han Dafu, et al. Research on preparation and early-age shrinkage properties of C60 steel self-compacting concrete[J]. China Concrete and Cement Products, 2017(1): 22-25, 30. doi: 10.3969/j.issn.1000-4637.2017.01.005 [11] 张志明. 超细粉煤灰替代硅灰制备高强高性能混凝土的研究[D]. 西安: 西安建筑科技大学, 2016. [12] 范梦甜, 王迎斌, 苏英, 等. 超细粉煤灰对水泥性能的影响及在混凝土中的应用研究[J]. 新型建筑材料, 2021, 48(8): 16-20, 37. doi: 10.3969/j.issn.1001-702X.2021.08.004Fan Mengtian, Wang Yingbin, Su Ying, et al. Study on the effect of ultra-fine fly ash on cement performance and its application in concrete[J]. New Building Materials, 2021, 48(8): 16-20, 37. doi: 10.3969/j.issn.1001-702X.2021.08.004 [13] 孙瑶, 曹瑞东, 张恩, 等. 超细粉煤灰改性高强混凝土力学性能试验研究[J]. 混凝土, 2020(8): 117-120. doi: 10.3969/j.issn.1002-3550.2020.08.026Sun Yao, Cao Ruidong, Zhang En, et al. Experimental study on mechanical properties of ultra fine fly ash modified high strength concrete[J]. Concrete, 2020(8): 117-120. doi: 10.3969/j.issn.1002-3550.2020.08.026 [14] 李长杰, 林杰, 尹耀霄, 等. 集料和膨胀剂对超高性能混凝土自收缩影响研究[J]. 武汉理工大学学报, 2019, 41(12): 25-30. https://www.cnki.com.cn/Article/CJFDTOTAL-WHGY201912005.htmLi Changjie, Lin Jie, Yin Yaoxiao, et al. Study on the influence of aggregate and expansion agent on autogenous shrinkage of ultra-high performance concrete[J]. Journal of Wuhan University of Technology, 2019, 41(12): 25-30. https://www.cnki.com.cn/Article/CJFDTOTAL-WHGY201912005.htm [15] 李青, 晏方, 陈宇良, 等. 外掺钢纤维混凝土早期力学性能的试验研究[J]. 混凝土, 2020(6): 102-105. doi: 10.3969/j.issn.1002-3550.2020.06.023Li Qing, Yan Fang, Chen Yuliang, et al. Experimental study on mechanical properties of concrete with adding steel fiber at early age[J]. Concrete, 2020(6): 102-105. doi: 10.3969/j.issn.1002-3550.2020.06.023 [16] Zhou X J, Mou T M, Fan B K, et al. Mechanical properties and volume deformation of steel fiberreinforced micro-expansive concrete filled steel tube[J]. Applied Mechanics and Materials, 2012, 204/205/206/207/208: 4083-4087. [17] 陈娟, 卢亦焱. 钢管钢纤维混凝土结构的性能研究[J]. 四川建筑科学研究, 2011, 37(1): 67-69. https://www.cnki.com.cn/Article/CJFDTOTAL-ACZJ201101019.htmChen Juan, Lu Yiyan. Study on properties of steel fiber reinforced concrete-filled steel tube structures[J]. Sichuan Building Science, 2011, 37(1): 67-69. https://www.cnki.com.cn/Article/CJFDTOTAL-ACZJ201101019.htm [18] 周孝军, 牟廷敏, 宋广, 等. 钢管钢纤维高强混凝土短柱轴压力学性能试验研究[J]. 建筑结构, 2020, 50(5): 130-134, 81. https://www.cnki.com.cn/Article/CJFDTOTAL-JCJG202005025.htmZhou Xiaojun, Mou Tingmin, Song Guang, et al. Experimental research on axial compressive mechanical behavior of steel fiber reinforced high strength concrete filled steel tube short columns[J]. Building Structure, 2020, 50(5): 130-134, 81. https://www.cnki.com.cn/Article/CJFDTOTAL-JCJG202005025.htm [19] Li Na, Lu Yiyan, Li Shan, et al. Axial compressive behaviour of steel fibre reinforced self-stressingand self-compacting concrete-filled steel tube columns[J]. Engineering Structures, 2020, 222: 111108. doi: 10.1016/j.engstruct.2020.111108 [20] 卢亦焱, 陈娟, 李杉. 钢管钢纤维高强混凝土短柱轴心受压试验研究[J]. 建筑结构学报, 2011, 32(10): 166-172. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB201110022.htmLu Yiyan, Chen Juan, Li Shan. Experimental research on steel fiber reinforced high strength concrete fill-ed steel tubular short columns subjected to axial compression load[J]. Journal of Building Struct-ures, 2011, 32(10): 166-172. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB201110022.htm [21] 卢亦焱, 严博, 李娜, 等. 钢管钢纤维自应力自密实柱轴心受压性能[J]. 土木工程与管理学报, 2017, 34(2): 1-4. https://www.cnki.com.cn/Article/CJFDTOTAL-WHCJ201702001.htmLu Yiyan, Yan Bo, Li Na, et al. Compressive behavior of steel tube columns filled with steel fiber reinforced self-stressing and self-compacting concrete[J]. Journal of Civil Engineering and Management, 2017, 34(2): 1-4. https://www.cnki.com.cn/Article/CJFDTOTAL-WHCJ201702001.htm [22] 李杉, 卢亦焱, 李娜, 等. 钢管纤维混凝土短柱轴压承载力计算分析[J]. 华北水利水电学院学报, 2012, 33(6): 59-63. https://www.cnki.com.cn/Article/CJFDTOTAL-HBSL201206013.htmLi Shan, Lu Yiyan, Li Na, et al. Bearing capacity of steel fiber reinforced high strength concrete filled steel tube under axial compression[J]. Journal of North China Institute of Water Conservancy and Hydroelectric Power, 2012, 33(6): 59-63. https://www.cnki.com.cn/Article/CJFDTOTAL-HBSL201206013.htm [23] 郭东明, 李妍妍, 亢鑫超, 等. 掺合料对钢管混凝土柱承载性能的影响[J]. 河南理工大学学报: 自然科学版, 2019, 38(2): 122-128. https://www.cnki.com.cn/Article/CJFDTOTAL-JGXB201902020.htmGuo Dongming, Li Yanyan, Kang Xinchao, et al. Effect of admixture on the bearing capacity of concrete filled steel tube columns[J]. Journal of Henan Polytechnic University: Natural Science, 2019, 38(2): 122-128. https://www.cnki.com.cn/Article/CJFDTOTAL-JGXB201902020.htm [24] 白杰, 许慧, 武俊宇, 等. C60自密实钢管混凝土配合比设计及应用[J]. 混凝土世界, 2021(6): 82-87. https://www.cnki.com.cn/Article/CJFDTOTAL-JZSJ202106018.htmBai Jie, Xu Hui, Wu Junyu, et al. Mix proportion design and application of C60 self-compacting concrete filled steel tube[J]. China Concrete, 2021(6): 82-87. https://www.cnki.com.cn/Article/CJFDTOTAL-JZSJ202106018.htm [25] 李妍妍. 掺合料对钢管混凝土力学性能影响研究[D]. 北京: 中国矿业大学(北京), 2019. [26] 李娜, 卢亦焱, 李杉, 等. 圆钢管自应力自密实混凝土短柱轴心受压性能研究[J]. 建筑结构学报, 2019, 40(11): 162-171. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB201911019.htmLi Na, Lu Yiyan, Li Shan, et al. Experimental study on self-stressing and self-compacting concrete-filled circular steel tube short columns subjected to axial compression[J]. Journal of Building Structure, 2019, 40(11): 162-171. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB201911019.htm [27] 韩林海. 钢管混凝土结构-理论与实践[M]. 3版. 北京: 科学出版社, 2018. [28] 毕继红, 霍琳颖, 赵云, 等. 钢纤维混凝土的本构模型及力学性能分析[J]. 湖南大学学报: 自然科学版, 2021, 48(7): 9-18. https://www.cnki.com.cn/Article/CJFDTOTAL-HNDX202107003.htmBi Jihong, Huo Linying, Zhao Yun, et al. Constitutive model and mechanical properties of steel fiber reinforced concrete[J]. Journal of Hunan University: Natural Sciences, 2021, 48(7): 9-18. https://www.cnki.com.cn/Article/CJFDTOTAL-HNDX202107003.htm [29] 朱康伟, 徐志洪, 曹志威, 等. 基于ABAQUS的钢纤维随机分布混凝土梁分析[C]//第二届土木工程与材料科学国际会议. 杭州, 2017, 5(7): 592-597. [30] 朱康伟. 钢纤维增强水泥基材料力学性能数值仿真及实验验证[D]. 南京: 南京理工大学, 2019. [31] 王庆利, 张旭, 王月, 等. 钢管自密实混凝土轴压构件的静力性能试验[J]. 沈阳建筑大学学报: 自然科学版, 2011, 27(5): 866-874. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJZ201105011.htmWang Qingli, Zhang Xu, Wang Yue, et al. Experimental study on static performance of the self-consolidating concrete filled steel tubular members under axial compressive load[J]. Journal of ShenyangJianzhu University: Natural Science, 2011, 27(5): 866-874. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJZ201105011.htm [32] 中国建筑工业出版社. 钢管混凝土结构技术规范: GB 50936—2014[S]. 北京: 中国建筑工业出版社, 2014. -

下载:

下载: