Migration and enrichment of arsenic during coal washing

-

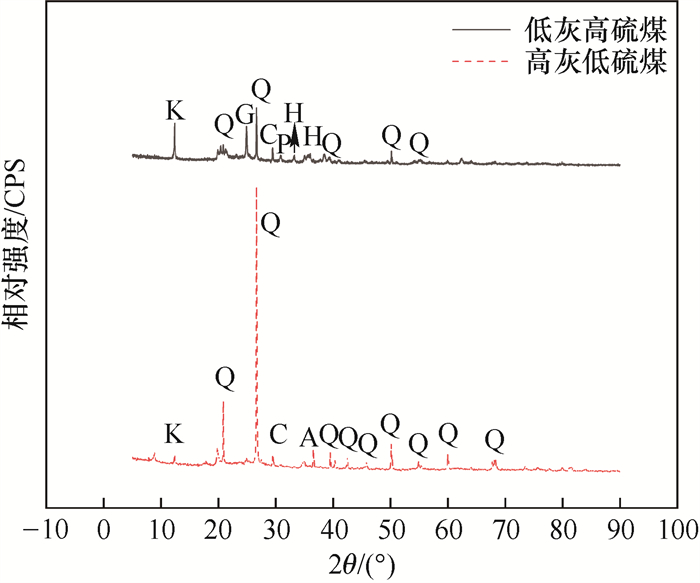

摘要: 在煤炭资源的加工利用过程中,部分重金属元素会在环境中富集,对环境和人体均有一定危害。选用内蒙古低灰高硫煤样和高灰低硫煤样进行浮沉和浮选试验,通过电感耦合等离子质谱仪(ICP-MS)、X射线衍射分析、X射线荧光分析、扫描电镜能谱分析、红外光谱分析等测试方法,研究重金属砷元素在煤中的赋存形式及洗选过程中的迁移富集规律。试验结果表明,在两种煤的矿物组成中,硅铝酸盐结合态存在的砷占比为最高,均达到50 % 以上,但是硅铝酸盐矿物种类并不相同,砷的赋存具有明显的差异性;浮沉结果显示低灰高硫煤中的砷主要与矿物质伴生集中在密度较大的部分,而高灰低硫煤主要富集在密度较低、有机质含量较高的部分;浮选中砷迁移规律也存在差异,低灰高硫煤中的砷在浮选过程中向尾煤中迁移,高灰低硫煤中的砷则相反,浮选过程中向精煤中迁移。以上规律表明,低灰高硫煤通过浮沉和浮选脱除砷是可行的,但是对于高灰低硫煤效果不好。Abstract: During the processing and utilization of coal resources, some heavy metal elements will be enriched in the environment, which is harmful to the environment and the human body.In this study, low-ash, high-sulfur coal samples and high-ash, low-sulfur coal samples from Inner Mongolia were selected for float-and-sink test and flotation, and were analyzed by inductively coupled plasma mass spectrometer (ICP-MS), X-ray diffraction analysis, X-ray fluorescence analysis, and scanning electron microscopy energy spectrum analysis.Infrared spectroscopy and other test methods were used to study the occurrence form of heavy metal arsenic in coal and its migration and enrichment law during the processing.The experimental results show that the two coal samples demonstrates the highest proportion of arsenic present in the aluminosilicate bound state, reaching more than 50 %, but the types of aluminosilicate minerals are not the same, and the occurrence of arsenic has obvious differences.Flotation results show that arsenic in low-ash and high-sulfur coal sample is mainly associated with minerals and concentrated in the denser part, while high-ash and low-sulfur coal is mainly concentrated in the part with lower density and higher organic content; there are also differences in the migration law of arsenic in flotation.During the flotation, the arsenic in low-ash and high-sulfur coal migrates to the tailings, while the arsenic in the high-ash and low-sulfur coal migrates to the clean coal.The above findings show that it is feasible to remove arsenic from low-ash and high-sulfur coal sample by flotation but the effect is not so good for high-ash and low-sulfur coal sample, indicating that the removal of arsenic must consider the impact of coal type.

-

Key words:

- Inner Mongolia coal /

- heavy metal elements /

- float-and-sink test /

- flotation /

- migration and enrichment

-

表 1 低灰高硫煤与高灰低硫煤的工业分析与元素分析

Table 1. Proximate analysis and ultimate analysis of LAHS and HALS samples

% 煤样 工业分析 元素分析 Mad Ad Vdaf FCdaf Cdaf Hdaf Odaf Ndaf St,daf 低灰高硫煤 1.44 17.69 44.96 55.04 80.06 5.25 9.47 1.50 3.71 高灰低硫煤 1.46 37.11 43.92 56.08 74.03 5.32 19.16 1.08 0.41 表 2 逐级化学提取方法

Table 2. Sequential chemical extraction procedure

提取溶液 提取时间/h 温度/℃ 提取的形态 5 mol/L HCl 6 60 碳酸盐、单硫化物、硫酸盐、磷酸盐及氧化物结合态 40%HF 6 60 硅铝酸盐结合态 5 mol/L HNO3 6 45 二硫化物结合态 H2O2 (pH值为2) 6 85 有机质结合态 表 3 煤样煤灰成分

Table 3. Ash composition of coal samples

% 样品 各组分质量分数 SiO2 Al2O3 CaO SO3 Fe2O3 TiO2 MgO K2O Na2O 其他 低灰高硫煤 44.05 39.67 6.22 3.36 3.12 1.31 1.18 0.276 0.273 0.541 高灰低硫煤 63.50 26.83 1.31 0.89 2.05 0.74 0.73 3.01 0.53 0.40 表 4 密度-灰分分布区间

Table 4. Summary of density and ash content

密度/

(g·cm-3)大浮沉灰分

范围/%小浮沉灰分

范围/%总灰分

范围/%< 1.3 3.49~4.73 3.04~3.90 3.04~4.73 1.3~1.4 7.62~9.06 5.81~6.05 5.81~9.06 1.4~1.5 13.85~18.99 11.38~12.45 11.38~18.99 1.5~1.6 23.47~30.45 14.88~19.91 14.88~30.45 1.6~1.8 36.53~47.82 29.31~30.46 29.31~47.82 >1.8 70.38~76.73 58.72~68.06 58.72~76.73 -

[1] 杨雨濛, 刘建忠, 陈明义, 等. 低阶煤及其热解半焦的超细粉碎特性[J]. 煤炭学报, 2021, 46(11): 3692-3698. doi: 10.13225/j.cnki.jccs.2021.0078Yang Yumeng, Liu Jianzhong, Chen Mingyi, et al. Superfine grinding characteristics of low-rank coals and their semi-coke[J]. Journal of China Coal Society, 2021, 46(11): 3692-3698. doi: 10.13225/j.cnki.jccs.2021.0078 [2] 康菲, 王静媛, 杨常青, 等. 进口蒙古国煤炭中有害微量元素的含量分布及赋存形态[J]. 洁净煤技术, 2018, 24(6): 32-36. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201806006.htmKang Fei, Wang Jingyuan, Yang Changqing, et al. Content and occurrence status of harmful elements in imported Mongolia coals[J]. Clean Coal Technology, 2018, 24(6): 32-36. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201806006.htm [3] 洪伟, 张衡, 张春田, 等. 煤品质变化及有害元素迁移的研究进展[J]. 洁净煤技术, 2016, 22(5): 108-112. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201605021.htmHong Wei, Zhang Heng, Zhang Chuntian, et al. Research progress on coal quality changes and migration of harmful elements[J]. Clean Coal Technology, 2016, 22(5): 108-112. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201605021.htm [4] Cao Q Y, Yang L, Ren W Y, et al. Spatial distribution of harmful trace elements in Chinese coalfields: an application of WebGIS technology[J]. Science of the Total Environment, 2021, 755: 142527. doi: 10.1016/j.scitotenv.2020.142527 [5] Finkelman R B, Orem W, Castranova V, et al. Health impacts of coal and coal use: possible solutions[J]. International Journal of Coal Geology, 2002, 50(1): 425-443. [6] 蔡文洁, 江研因. 甲基汞暴露健康风险评价的研究进展[J]. 环境与健康杂志, 2008, 25(1): 77-81. doi: 10.3969/j.issn.1001-5914.2008.01.031Cai Wenjie, Jiang Yanyin. Research advance of health risk assessment on methylmercury exposure[J]. Journal of Environment and Health, 2008, 25(1): 77-81. doi: 10.3969/j.issn.1001-5914.2008.01.031 [7] 吴攀, 刘丛强, 杨元根, 等. 矿山环境中(重)金属的释放迁移地球化学及其环境效应[J]. 矿物学报, 2001, 21(2): 213-218. doi: 10.3321/j.issn:1000-4734.2001.02.018Wu Pan, Liu Congqiang, Yang Yuangen, et al. Release and transport of (heavy) metals and their environmental effect in mining activities[J]. Acta Mineralogica Sinica, 2001, 21(2): 213-218. doi: 10.3321/j.issn:1000-4734.2001.02.018 [8] 刘慧. 马鞍山重点矿区土壤重金属污染评价研究[D]. 合肥: 合肥工业大学, 2012. [9] 金肇岩. 煤中砷、汞的淋滤迁移规律研究[D]. 成都: 成都理工大学, 2011. [10] 田贺忠, 曲益萍. 2005年中国燃煤大气砷排放清单[J]. 环境科学, 2009, 30(4): 956-962. doi: 10.3321/j.issn:0250-3301.2009.04.003Tian Hezhong, Qu Yiping. Inventories of atmospheric arsenic emissions from coal combustion in China, 2005[J]. Environmental Science, 2009, 30(4): 956-962. doi: 10.3321/j.issn:0250-3301.2009.04.003 [11] 党钾涛, 解强. 煤中有害微量元素及其在加工转化中的行为研究进展[J]. 现代化工, 2016, 36(7): 59-63, 65. https://www.cnki.com.cn/Article/CJFDTOTAL-XDHG201607016.htmDang Jiatao, Xie Qiang. Hazardous trace elements in coal and their behaviors during processing and utilization[J]. Modern Chemical Industry, 2016, 36(7): 59-63, 65. https://www.cnki.com.cn/Article/CJFDTOTAL-XDHG201607016.htm [12] 王云鹤, 李海滨, 黄海涛, 等. 重金属元素在煤热解过程中的分布迁移规律[J]. 煤炭转化, 2002, 25(3): 37-42. doi: 10.3969/j.issn.1004-4248.2002.03.008Wang Yunhe, Li Haibin, Huang Haitao, et al. Distribution and transport of heavy metal elements during coal pyrolysis[J]. Coal Conversion, 2002, 25(3): 37-42. doi: 10.3969/j.issn.1004-4248.2002.03.008 [13] 石应杰. 改性钒钛钢渣吸附烟气HgO的研究[D]. 北京: 中国矿业大学(北京), 2016. [14] 王文峰, 秦勇, 宋党育. 煤中有害元素的洗选洁净潜势[J]. 燃料化学学报, 2003, 31(4): 295-299. doi: 10.3969/j.issn.0253-2409.2003.04.002Wang Wenfeng, Qin Yong, Song Dangyu. Cleaning potential of hazardous elements during coal washing[J]. Journal of Fuel Chemistry and Technology, 2003, 31(4): 295-299. doi: 10.3969/j.issn.0253-2409.2003.04.002 [15] 范玉强. 我国部分煤中重金属含量、赋存及排放控制研究[D]. 鞍山: 辽宁科技大学, 2016. [16] 王文峰, 秦勇. 煤洁净过程中有害元素和矿物的分配规律[M]. 徐州: 中国矿业大学出版社, 2011. [17] 秦勇, 王文峰, 宋党育. 太西煤中有害元素在洗选过程中的迁移行为与机理[J]. 燃料化学学报, 2002, 30(2): 147-150. https://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200202009.htmQin Yong, Wang Wenfeng, Song Dangyu. Migrating behavior and mechanism of deleterious elements in Taixi coals during cleaning process[J]. Journal of Fuel Chemistry and Technology, 2002, 30(2): 147-150. https://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200202009.htm [18] Luttrell G H, Kohmuench J N, Yoon R H. An evaluation of coal preparation technologies for controlling trace element emissions[J]. Fuel Processing Technology, 2000, 65/66: 407-422. doi: 10.1016/S0378-3820(99)00107-1 [19] Duan P P, Wang W F, Liu X H, et al. Distribution of As, Hg and other trace elements in different size and density fractions of the Reshuihe high-sulfur coal, Yunnan Province, China[J]. International Journal of Coal Geology, 2017, 173: 129-141. doi: 10.1016/j.coal.2017.02.013 [20] Wang W F, Qin Y, Sang S X, et al. Partitioning of minerals and elements during preparation of Taixi coal, China[J]. Fuel, 2006, 85(1): 57-67. doi: 10.1016/j.fuel.2005.05.017 [21] 张博. 煤中有害微量元素的洁净潜势分析[J]. 洁净煤技术, 2015, 21(4): 20-24. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201504006.htmZhang Bo. Cleaning potentiality analysis of harmful microelements in coal[J]. Clean Coal Technology, 2015, 21(4): 20-24. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201504006.htm [22] 何龙, 沙杰. 高硫煤破碎脱硫效果的分析研究[J]. 山西焦煤科技, 2016, 40(2): 35-37, 42. https://www.cnki.com.cn/Article/CJFDTOTAL-XSKJ201602011.htmHe Long, Sha Jie. Analyze and research on crushing desulfurization effect of high sulfur coal[J]. Shanxi Coking Coal Science & Technology, 2016, 40(2): 35-37, 42. https://www.cnki.com.cn/Article/CJFDTOTAL-XSKJ201602011.htm [23] 熊明金, 黄叶钿, 符剑刚, 等. 高硫煤深度浮选联合化学氧化脱灰脱硫提质研究[J]. 洁净煤技术, 2020, 26(4): 64-71. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS202004008.htmXiong Mingjin, Huang Yetian, Fu Jiangang, et al. Study on deashing, desulfurization and upgrading of high sulfur coal by deep-flotation combined with chemical oxidation[J]. Clean Coal Technology, 2020, 26(4): 64-71. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS202004008.htm [24] 宋杨. 贵州普安某高硫煤脱硫降灰试验研究[D]. 贵阳: 贵州大学, 2020. [25] 李果兰. 筛分浮沉试验对高硫煤脱硫效果的分析研究[J]. 山西化工, 2014, 34(6): 46-48. https://www.cnki.com.cn/Article/CJFDTOTAL-SDHW201406018.htmLi Guolan. Analysis of screening test and float-and-sink test to high-sulfur coal desulfurization[J]. Shanxi Chemical Industry, 2014, 34(6): 46-48. https://www.cnki.com.cn/Article/CJFDTOTAL-SDHW201406018.htm [26] 蔡会武, 杜美利, 王水利. 陕北高硫煤筛分浮沉脱除硫及灰分实验研究[J]. 煤炭转化, 2007, 30(1): 57-59, 77. https://www.cnki.com.cn/Article/CJFDTOTAL-MTZH200701013.htmCai Huiwu, Du Meili, Wang Shuili. Floating and sinking tests for screening of high sulfur coal[J]. Coal Conversion, 2007, 30(1): 57-59, 77. https://www.cnki.com.cn/Article/CJFDTOTAL-MTZH200701013.htm [27] 刘学雷. 我国选煤技术发展现状及趋势分析[J]. 选煤技术, 2018(6): 12-15. https://www.cnki.com.cn/Article/CJFDTOTAL-XMJS201806004.htmLiu Xuelei. Status quo and developing trend of China's coal preparation technology[J]. Coal Preparation Technology, 2018(6): 12-15. https://www.cnki.com.cn/Article/CJFDTOTAL-XMJS201806004.htm [28] 戴和武, 陈文敏. 用浮沉、筛分法脱煤中黄铁矿硫的研究[J]. 煤炭分析及利用, 1991, 6(2): 4-11. https://www.cnki.com.cn/Article/CJFDTOTAL-MTFX199102001.htmDai Hewu, Chen Wenmin. Study on the removal of pyrite from coal by floating-sinking and sieving methods[J]. Coal Analysis and Utilization, 1991, 6(2): 4-11. https://www.cnki.com.cn/Article/CJFDTOTAL-MTFX199102001.htm [29] 王庆峰. 中高硫煤浮选脱硫脱灰试验研究[D]. 青岛: 青岛理工大学, 2013. -

下载:

下载: