Numerical simulation on the effect of drilling engineering factors on coal fines output in coalbed methane horizontal wells: a case study of Liulin block

-

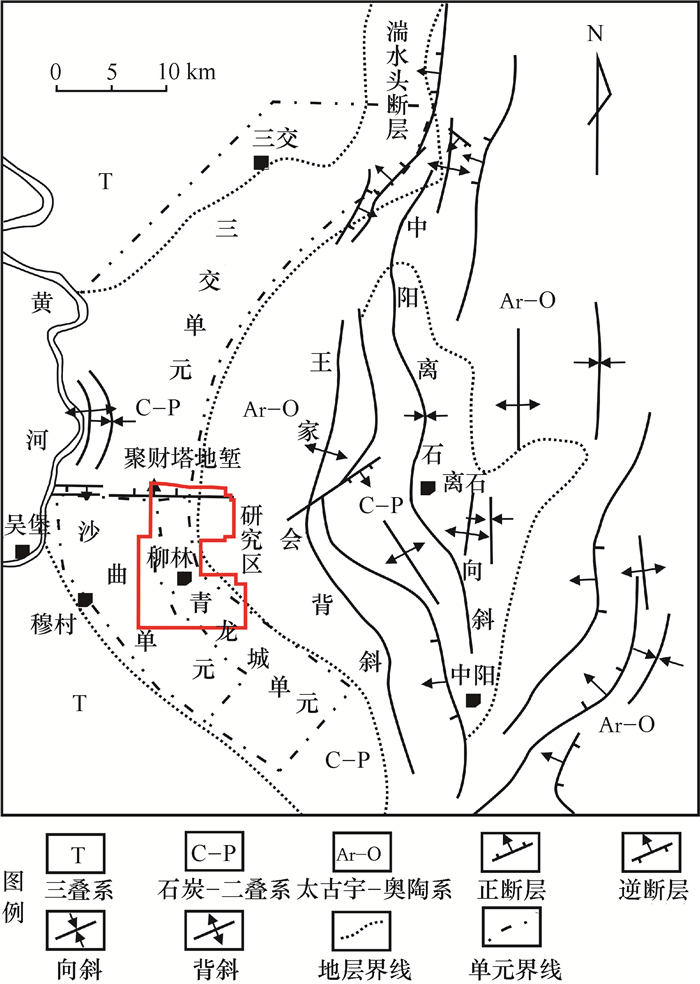

摘要: 煤粉产出是制约煤层气开发的关键因素。影响煤粉产出的因素包括静态和动态因素,钻井工程是动态因素中影响煤粉产出的重要因素之一。以柳林煤层气区块为例,从井壁稳定性角度出发,运用ANSYS软件建立了二维、三维模型,分别模拟了不同钻井方位、钻井液密度、井眼半径、井斜情况下井壁的受力和变形,分析了煤层气水平井钻井工程因素对煤粉产出的影响。研究表明,井眼大小和井斜对煤粉产出的影响较大,而井眼方位和钻井液密度对煤粉产出的影响较小;井眼方位沿最大水平地应力方向时,井周等效应力差值最大,应力集中最明显;钻井液密度过大会导致井壁拉伸破坏;水平井钻进过程中,井眼半径越大、井斜越大,越易产生煤粉。为了减少钻井因素导致的煤粉产生,建议研究区水平井钻进时,井眼方位选择沿最小水平地应力方向,水平段选用清水钻进,水平段井眼倾角尽量与煤层倾角保持一致。研究成果为煤粉管控措施提供参考。Abstract: The coal fines output is the key factor restricting the development of coalbed methane.Factors affecting coal fines output include static factors and dynamic factors.Drilling engineering is one of the important dynamic factors affecting coal fines output.Taking Liulin coalbed methane block as an example, this study established 2D and 3D models by ANSYS software from the perspective of the wellbore stability, and simulated the force and deformation of the borehole wall under different drilling orientations, drilling fluid density, wellbore size, and wellbore inclination.The influence of factors in drilling engineering on the coal fines production was analyzed for the coalbed methane horizontal well.Results show that borehole size and inclination on coal fines production exert greater effect than borehole orientation and drilling fluid density.When the borehole orientation is along the direction of the maximum horizontal in-situ stress, it demonstrates the biggest difference in the equivalent stress around the borehole, and the most obvious stress concentration.Excessive density drilling fluid will lead to tensile failure of the wellbore.In the process of horizontal well drilling, the larger the radius of the wellbore and the larger the inclination of the well, the easier it is to generate coal fines.In order to reduce the generation of coal fines caused by drilling factors, it is suggested that when drilling horizontal wells in the study area, the borehole orientation should be along the direction of the minimum horizontal in-situ stress, the horizontal section should be drilled with clear water, and the inclination of the horizontal section should be consistent with the inclination of the coal seam.The research results provide a theoretical basis for the control measures of coal fines.

-

表 1 4号煤层试验井结果数据

Table 1. Results from test wells

试验井编号 试验点深度/m 最小水平地应力/MPa 最大水平地应力/MPa ED1 479.32 8.82 12.93 ED2 862.83 12.11 17.7 EP2 1 013.59 14.87 21.57 EP3 710.07 12.48 17.51 EP5 564.8 8.19 13.08 表 2 4号煤层煤岩力学参数[38]

Table 2. Mechanical parameters of coal[38]

参数 数值 抗压强度/MPa 9.07 抗拉强度/MPa 0.28 弹性模量/GPa 1.04 泊松比 0.33 黏聚力/MPa 4.22 内摩擦角/(°) 37.69 上覆地层压力/MPa 16.192 最大水平地应力/MPa 15.17 最小水平地应力/MPa 10.28 -

[1] 魏迎春, 张劲, 曹代勇, 等. 煤层气开发中煤粉问题的研究现状及研究思路[J]. 煤田地质与勘探, 2020, 48(6): 116-124. doi: 10.3969/j.issn.1001-1986.2020.06.016Wei Yingchun, Zhang Jin, Cao Daiyong, et al. Research status and thoughts for coal fines during CBM development[J]. Coal Geology & Exploration, 2020, 48(6): 116-124. doi: 10.3969/j.issn.1001-1986.2020.06.016 [2] Wei Y C, Cao D Y, Yuan Y, et al. Characteristics of pulverized coal during coalbed methane drainage in Hancheng block, Shaanxi Province, China[J]. Energy Exploration & Exploitation, 2013, 31(5): 745-757. [3] Zhao X Z, Liu S Q, Sang S X, et al. Characteristics and generation mechanisms of coal fines in coalbed methane wells in the southern Qinshui Basin, China[J]. Journal of Natural Gas Science and Engineering, 2016, 34: 849-863. doi: 10.1016/j.jngse.2016.07.063 [4] 魏迎春, 曹代勇, 袁远, 等. 韩城区块煤层气井产出煤粉特征及主控因素[J]. 煤炭学报, 2013, 38(8): 1424-1429. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201308022.htmWei Yingchun, Cao Daiyong, Yuan Yuan, et al. Characteristics and controlling factors of pulverized coal during coalbed methane drainage in Hancheng area[J]. Journal of China Coal Society, 2013, 38(8): 1424-1429. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201308022.htm [5] 魏迎春, 张傲翔, 姚征, 等. 韩城区块煤层气排采中煤粉产出规律研究[J]. 煤炭科学技术, 2014, 42(2): 85-89. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201402024.htmWei Yingchun, Zhang Aoxiang, Yao Zheng, et al. Research on output laws of pulverized coal during coalbed methane drainage in Hancheng block[J]. Coal Science and Technology, 2014, 42(2): 85-89. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201402024.htm [6] 魏迎春, 李超, 曹代勇, 等. 煤层气开发中煤粉产出机理及管控措施[J]. 煤田地质与勘探, 2018, 46(2): 68-73. doi: 10.3969/j.issn.1001-1986.2018.02.011Wei Yingchun, Li Chao, Cao Daiyong, et al. The output mechanism and control measures of the pulverized coal in coalbed methane development[J]. Coal Geology & Exploration, 2018, 46(2): 68-73. doi: 10.3969/j.issn.1001-1986.2018.02.011 [7] Wei Y C, Li C, Cao D Y, et al. New progress on the coal fines affecting the development of coalbed methane[J]. Acta Geologica Sinica-English Edition, 2018, 92(5): 2060-2062. doi: 10.1111/1755-6724.13708 [8] Shi Z J, Zhao Y Z, Qi H J, et al. Research and application of drilling technology of extended-reach horizontally-intersected well used to extract coalbed methane[J]. Procedia Earth and Planetary Science, 2011, 3: 446-454. doi: 10.1016/j.proeps.2011.09.119 [9] 孙延明, 张遂安, 杨红军, 等. 影响煤层气钻井工程的工程地质因素分析[J]. 中国煤炭地质, 2016, 28(12): 62-66. doi: 10.3969/j.issn.1674-1803.2016.12.11Sun Yanming, Zhang Suian, Yang Hongjun, et al. Analysis of engineering geological factors impacting CBM well drilling engineering[J]. Coal Geology of China, 2016, 28(12): 62-66. doi: 10.3969/j.issn.1674-1803.2016.12.11 [10] Ju W, Shen J, Qin Y, et al. In-situ stress state in the Linxing region, eastern Ordos Basin, China: implications for unconventional gas exploration and production[J]. Marine and Petroleum Geology, 2017, 86: 66-78. doi: 10.1016/j.marpetgeo.2017.05.026 [11] Florkowska L. The application of numerical analysis in determining the state of the rock mass around directional wells[J]. Procedia Engineering, 2017, 191: 785-794. doi: 10.1016/j.proeng.2017.05.245 [12] Aslannezhad M, Keshavarz A, Kalantariasl A. Evaluation of mechanical, chemical, and thermal effects on wellbore stability using different rock failure criteria[J]. Journal of Natural Gas Science and Engineering, 2020, 78: 103276. doi: 10.1016/j.jngse.2020.103276 [13] Zhang X B, Wang W Y, Yang M. Study on deformation and destabilization characteristics and modes of drainage borehole[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020, 42(19): 2448-2459. doi: 10.1080/15567036.2019.1607944 [14] 曹代勇, 宁树正, 郭爱军, 等. 中国煤田构造格局及其基本特征[J]. 矿业科学学报, 2016, 1(1): 1-8. http://kykxxb.cumtb.edu.cn/article/id/4Cao Daiyong, Ning Shuzheng, Guo Aijun, et al. Basic characteristics of coalfield tectonic framework in China[J]. Journal of Mining Science and Technology, 2016, 1(1): 1-8. http://kykxxb.cumtb.edu.cn/article/id/4 [15] 冯立杰, 江涛, 岳俊举, 等. 煤层气开采钻井工程关键影响因素识别研究[J]. 煤矿安全, 2018, 49(12): 177-180. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201812045.htmFeng Lijie, Jiang Tao, Yue Junju, et al. Identification of key influencing factors of CBM drilling engineering[J]. Safety in Coal Mines, 2018, 49(12): 177-180. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201812045.htm [16] 王庆伟, 曹代勇, 王佟. 煤层气裸眼洞穴完井造成的应力集中带与煤粉产出的关系[J]. 煤田地质与勘探, 2013, 41(6): 35-37. doi: 10.3969/j.issn.1001-1986.2013.06.009Wang Qingwei, Cao Daiyong, Wang Tong. Relationship between the stress-concentrated zone caused by cavity-completed wells and the coal powder output[J]. Coal Geology & Exploration, 2013, 41(6): 35-37. doi: 10.3969/j.issn.1001-1986.2013.06.009 [17] Lin H, Kang W H, Oh J, et al. Numerical simulation on borehole breakout and borehole size effect using discrete element method[J]. International Journal of Mining Science and Technology, 2020, 30(5): 623-633. doi: 10.1016/j.ijmst.2020.05.019 [18] 李宁, 郑何光, 卢俊安, 等. 库车北部构造侏罗系煤层井壁稳定对策研究[J]. 西南石油大学学报: 自然科学版, 2021, 43(4): 26-34. https://www.cnki.com.cn/Article/CJFDTOTAL-XNSY202104005.htmLi Ning, Zheng Heguang, Lu Junan, et al. A study on stabilization strategy of Jurassic coal strata in northern Kuche structural belt[J]. Journal of Southwest Petroleum University: Science & Technology Edition, 2021, 43(4): 26-34 https://www.cnki.com.cn/Article/CJFDTOTAL-XNSY202104005.htm [19] 李恒, 何世明, 汤明, 等. 塔里木盆地深部煤层失稳机理及防塌钻井液技术[J]. 煤田地质与勘探, 2019, 47(4): 212-218. doi: 10.3969/j.issn.1001-1986.2019.04.032Li Heng, He Shiming, Tang Ming, et al. Instability mechanism and anti-sloughing drilling fluid technique for deep coal seam of Tarim Basin[J]. Coal Geology & Exploration, 2019, 47(4): 212-218. doi: 10.3969/j.issn.1001-1986.2019.04.032 [20] 季长江, 郝春生, 信凯, 等. 煤层气井固井泥浆储层伤害机理研究[J]. 煤炭工程, 2017, 49(11): 116-118, 122.Ji Changjiang, Hao Chunsheng, Xin Kai, et al. Study on cementing damage mechanism for reservoir of CBM well[J]. Coal Engineering, 2017, 49(11): 116-118, 122. [21] 王之东, 黎立云, 刘一, 等. 型煤模型冲击失稳破坏中能量释放分析[J]. 矿业科学学报, 2018, 3(6): 527-535. http://kykxxb.cumtb.edu.cn/article/id/181Wang Zhidong, Li Liyun, Liu Yi, et al. Analysis of energy release in impact instability damage of briquette model[J]. Journal of Mining Science and Technology, 2018, 3(6): 527-535. http://kykxxb.cumtb.edu.cn/article/id/181 [22] 蔡永博, 王凯, 徐超. 煤岩单体及原生组合体变形损伤特性对比试验研究[J]. 矿业科学学报, 2020, 5(3): 278-283. http://kykxxb.cumtb.edu.cn/article/id/290Cai Yongbo, Wang Kai, Xu Chao. Comparative experimental study on deformation and damage characteristics of single coal rock and primary coal-rock combination[J]. Journal of Mining Science and Technology, 2020, 5(3): 278-283. http://kykxxb.cumtb.edu.cn/article/id/290 [23] 王茂盛, 朱晔, 李永亮, 等. 基于模糊聚类方法的煤巷围岩稳定性分类研究[J]. 矿业科学学报, 2018, 3(3): 238-245. http://kykxxb.cumtb.edu.cn/article/id/143Wang Maosheng, Zhu Ye, Li Yongliang, et al. Study on stability classification of surrounding rock of coal gateway based on fuzzy clustering method[J]. Journal of Mining Science and Technology, 2018, 3(3): 238-245. http://kykxxb.cumtb.edu.cn/article/id/143 [24] Akbarpour M, Abdideh M. Wellbore stability analysis based on geomechanical modeling using finite element method[J]. Modeling Earth Systems and Environment, 2020, 6(2): 617-626. [25] Ran X F, Zhang B, Wei W, et al. Reservoir protection and well completion technology for multi-branch horizontal wells in coalbed methane[J]. Arabian Journal of Geosciences, 2021, 14(9): 1-8. [26] Lyu S F, Wang S W, Chen X J, et al. Experimental study of a degradable polymer drilling fluid system for coalbed methane well[J]. Journal of Petroleum Science and Engineering, 2019, 178: 678-690. [27] Mahmoud H, Hamza A, Nasser M S, et al. Hole cleaning and drilling fluid sweeps in horizontal and deviated wells: comprehensive review[J]. Journal of Petroleum Science and Engineering, 2020, 186: 106748. [28] 杜坤, 李秀灵, 王本利, 等. 无黏土水基钻井液在长庆油田米38区块水平井的应用[J]. 钻井液与完井液, 2021, 38(3): 331-336. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJYW202103011.htmDu Kun, Li Xiuling, Wang Benli, et al. Application of a clay-free low solids water based drilling fluid in block mi-38 in Changqing oilfield[J]. Drilling Fluid & Completion Fluid, 2021, 38(3): 331-336. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJYW202103011.htm [29] 刘升贵, 彭智高, 李仲力, 等. 煤层气水平分支井稳定性的数值分析[J]. 辽宁工程技术大学学报: 自然科学版, 2015, 34(7): 769-773.Liu Shenggui, Peng Zhigao, Li Zhongli, et al. Numerical analysis of coalbed methane horizontal branch well stability[J]. Journal of Liaoning Technical University: Natural Science, 2015, 34(7): 769-773. [30] 陈颖杰, 邓传光, 马天寿. 井壁失稳风险的可靠度理论评价方法[J]. 天然气工业, 2019, 39(11): 97-104. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG201911021.htmChen Yingjie, Deng Chuanguang, Ma Tianshou. A risk assessment method of wellbore instability based on the reliability theory[J]. Natural Gas Industry, 2019, 39(11): 97-104. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG201911021.htm [31] 李玉梅, 苏中, 张涛, 等. 欠平衡钻井煤层井壁稳定有限元数值计算研究[J]. 系统仿真学报, 2018, 30(11): 4249-4255. https://www.cnki.com.cn/Article/CJFDTOTAL-XTFZ201811026.htmLi Yumei, Su Zhong, Zhang Tao, et al. Numerical simulation of borehole stability in underbalanced drilling coal seam[J]. Journal of System Simulation, 2018, 30(11): 4249-4255. https://www.cnki.com.cn/Article/CJFDTOTAL-XTFZ201811026.htm [32] 孙正财, 刘向君, 梁利喜, 等. 煤层气井割理煤岩井壁稳定性影响因素分析[J]. 煤炭科学技术, 2018, 46(4): 117-122. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201804020.htmSun Zhengcai, Liu Xiangjun, Liang Lixi, et al. Analysis on impact factors of borehole wall stability of coalbed methane well[J]. Coal Science and Technology, 2018, 46(4): 117-122. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201804020.htm [33] 张光福, 何世明, 汤明, 等. 基于3DEC离散元的煤层井壁稳定性[J]. 科学技术与工程, 2020, 20(4): 1367-1373. https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS202004011.htmZhang Guangfu, He Shiming, Tang Ming, et al. Borehole stability of coal seam based on 3DEC[J]. Science Technology and Engineering, 2020, 20(4): 1367-1373. https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS202004011.htm [34] 张丹丹, 冯雨实, 李永臣, 等. 基于有限元软件的煤层气水平井井壁稳定数值模拟[J]. 煤矿安全, 2018, 49(3): 144-147. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201803039.htmZhang Dandan, Feng Yushi, Li Yongchen, et al. Numerical simulation of wellbore stability for CBM horizontal well by finite element software[J]. Safety in Coal Mines, 2018, 49(3): 144-147. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201803039.htm [35] 张劲, 林亮, 魏迎春, 等. 柳林区块煤层气水平井煤粉产出特征及影响因素研究[J]. 中国煤炭地质, 2021, 33(10): 11-16, 70. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMT202110002.htmZhang Jin, Lin Liang, Wei Yingchun, et al. Study on CBM horizontal well coal fines generation features and impacting factors in Liulin block[J]. Coal Geology of China, 2021, 33(10): 11-16, 70. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMT202110002.htm [36] 孟召平, 蓝强, 刘翠丽, 等. 鄂尔多斯盆地东南缘地应力、储层压力及其耦合关系[J]. 煤炭学报, 2013, 38(1): 122-128. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201301019.htmMeng Zhaoping, Lan Qiang, Liu Cuili, et al. In-situ stress and coal reservoir pressure in Southeast margin of Ordos Basin and their coupling relations[J]. Journal of China Coal Society, 2013, 38(1): 122-128. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201301019.htm [37] 李勇, 汤达祯, 许浩, 等. 鄂尔多斯盆地柳林地区煤储层地应力场特征及其对裂隙的控制作用[J]. 煤炭学报, 2014, 39(S1): 164-168.Li Yong, Tang Dazhen, Xu Hao, et al. Characteristic of in situ stress field in Liulin area, Ordos Basin and its control on coal fractures[J]. Journal of China Coal Society, 2014, 39(S1): 164-168. [38] 刘帅帅. 柳林矿区南部煤储层特征及煤层气开发单元划分[D]. 徐州: 中国矿业大学, 2019. [39] Guo Y L, Cao L W, Sang S X, et al. CBM drilling technical parameter optimization methodology and software development: a case study of LUAN mining area[J]. Anais Da Academia Brasileira De Ciências, 2021, 93(1): e20190346. -

下载:

下载: