Effects of slag powder/metakaolin on the early performance of natural hydraulic lime

-

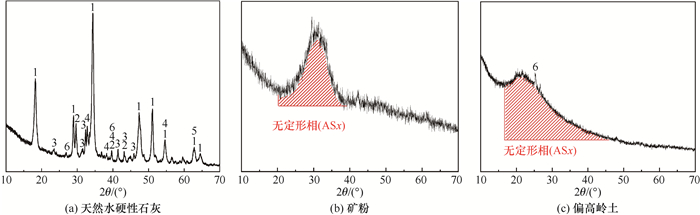

摘要: 天然水硬性石灰(NHL) 在古建筑修缮工程中的应用效果是水泥和传统气硬性石灰所无法比拟的,但早期性能发展偏慢的特性使其应用受限。本文研究了矿粉/偏高岭土改性NHL早期硬化过程中物理力学性能、水化放热特性、物相组成和转变以及微观结构演变过程,系统地评估了矿粉/偏高岭土对NHL基材料早期性能发展的影响。结果表明:矿粉可以改善NHL基砂浆的流动性;矿粉/偏高岭土通过火山灰反应生成水化铝酸钙(C3AH6)、水化碳铝酸钙(C4AĈH11) 以及水化硅酸钙(C—S—H),可促进NHL基材料凝结硬化、显著提高其抗压及抗折强度。本研究为推动火山灰质材料复合NHL在古建筑修复工程中的应用提供参考。Abstract: Natural Hydraulic Lime (NHL) has exceptional application in restoring ancient buildings compared to Portland cement and conventional air-hardening lime, but the characteristic of slow early performance development limits its fields of application. This paper studied the physical and mechanical properties, hydration exothermic properties, phase composition and transformation, and microstructure evolution of slag powder/metakaolin composite NHL during the early hardening process. The influence of slag powder/metakaolin on the hardening process and performance development of NHL are systematically evaluated. Results show that slag powder can improve the fluidity of NHL-based mortar; slag powder/metakaolin generates calcium aluminate hydrate (C3AH6), calcium carboaluminate hydrate (C4AĈH11) and calcium silicate hydrate (C—S—H) through pozzolanic reaction to promote the setting and hardening of NHL-based materials and significantly improve their compressive and flexural strength. This study provides reference for promoting the application of pozzolanic material composite NHL in the restoration of ancient buildings.

-

Key words:

- natural hydraulic lime /

- slag powder /

- metakaolin /

- pozzolanic reaction /

- early performance

-

表 1 原材料的化学组成

Table 1. Chemical composition of raw materials

原材料 化学组成质量分数/% 堆积密度/(g·cm-3) CaO SiO2 Fe2O3 Al2O3 MgO K2O SO3 Na2O 天然水硬性石灰 80.13 7.90 1.52 2.56 6.18 0.71 0.92 0.08 0.56 矿粉 38.45 35.03 0.63 14.95 9.31 0.38 1.13 0.12 0.92 偏高岭土 0.38 58.86 1.12 38.81 0.21 0.54 0.02 0.06 1.28 表 2 天然水硬性NHL基净浆配合比

Table 2. Mix proportions of NHL-based pastes

样品 水灰比 质量组分配合比/% 天然水硬性石灰 矿粉 偏高岭土 NHL 0.55 100 0 0 S10NHL 90 10 0 S20NHL 80 20 0 M10NHL 90 0 10 M20NHL 80 0 20 表 3 各NHL基浆体的水化放热特征值

Table 3. Characteristic values of the hydration heat for NHL-based pastes

样品 NHL S10NHL S20NHL M10NHL M20NHL 水化加速期出现的时间/h 4.74 4.53 3.20 1.96 1.52 第1个放热峰峰值/(mW·g-1) 26.21 24.90 19.36 19.19 20.95 第2个放热峰出现的时间/h 7.47 10.12 12.39 4.43 2.72 第2个放热峰峰值/(mW·g-1) 0.27 0.35 0.39 0.41 0.46 第3个放热峰出现的时间/h — — — 23.68 8.86 第3个放热峰峰值/(mW·g-1) — — — 0.29 0.43 累积放热量/(J·g-1) 0~1 h 13.71 13.63 9.37 10.81 11.36 0~12 h 23.82 24.97 24.45 24.41 28.23 0~72 h 40.85 56.85 67.99 69.73 83.53 0~168 h 45.74 71.52 82.90 87.39 104.67 表 4 NHL基硬化浆体28 d时的孔结构参数

Table 4. Pore structure parameter of NHL-based pastes at 28 d

样品 最可几孔径/nm 孔隙率/% 孔径分布/% 小于20 nm 20~100 nm 100~200 nm 大于200 nm NHL 927.21 48.06 2.07 5.27 3.14 89.52 S10NHL 934.28 47.08 2.74 11.20 2.60 83.46 S20NHL 879.53 46.69 5.18 14.61 3.94 76.27 M10NHL 645.17 46.52 2.86 19.47 4.89 72.78 M20NHL 352.83 46.13 5.89 32.25 6.72 55.14 -

[1] Technical Committee CEN/TC 51 "Cement and building limes". BS EN 459-1—2015 Building lime-Part 1: Definitions, specifications and conformity criteria[S]. Europe: British Standards Institution, 2015. [2] Vavričuk A, Bokan-Bosiljkov V, Kramar S. The influence of metakaolin on the properties of natural hydraulic lime-based grouts for historic masonry repair[J]. Construction and Building Materials, 2018, 172: 706-716. doi: 10.1016/j.conbuildmat.2018.04.007 [3] Grilo J, Silva A S, Faria P, et al. Mechanical and mineralogical properties of natural hydraulic lime-metakaolin mortars in different curing conditions[J]. Construction and Building Materials, 2014, 51: 287-294. doi: 10.1016/j.conbuildmat.2013.10.045 [4] Garijo L, Zhang X X, Ruiz G, et al. Age effect on the mechanical properties of natural hydraulic and aerial lime mortars[J]. Construction and Building Materials, 2020, 236: 117573. doi: 10.1016/j.conbuildmat.2019.117573 [5] Moon K Y, Cho J S, Choi M K, et al. Effect of blast furnace slag on the hydration properties in natural hydraulic lime[J]. Journal of Ceramic Processing Research, 2016, 17(2): 122-128. [6] Luo K, Li J, Lu Z Y, et al. Effect of nano-SiO2 on early hydration of natural hydraulic lime[J]. Construction and Building Materials, 2019, 216: 119-127. doi: 10.1016/j.conbuildmat.2019.04.269 [7] 马炳坚. 谈谈文物古建筑的保护修缮[J]. 古建园林技术, 2002(4): 58-61, 64. https://www.cnki.com.cn/Article/CJFDTOTAL-GJYL200204016.htmMa Bingjian. Talking about the protection and repair of cultural relics and ancient buildings[J]. Traditional Chinese Architecture and Gardens, 2002(4): 58-61, 64. https://www.cnki.com.cn/Article/CJFDTOTAL-GJYL200204016.htm [8] Navrátilová E, Rovnaníková P. Pozzolanic properties of brick powders and their effect on the properties of modified lime mortars[J]. Construction and Building Materials, 2016, 120: 530-539. doi: 10.1016/j.conbuildmat.2016.05.062 [9] Aggelakopoulou E, Bakolas A, Moropoulou A. Properties of lime-metakolin mortars for the restoration of historic masonries[J]. Applied Clay Science, 2011, 53(1): 15-19. doi: 10.1016/j.clay.2011.04.005 [10] Zhang D J, Wang D M, Zhao J H, et al. Assessment of the thermal and microstructural properties of metakaolin-air lime based materials at an early age[J]. Applied Clay Science, 2020, 191: 105619. doi: 10.1016/j.clay.2020.105619 [11] Nunes C, Mácová P, Frankeová D, et al. Influence of linseed oil on the microstructure and composition of lime and lime-metakaolin pastes after a long curing time[J]. Construction and Building Materials, 2018, 189: 787-796. doi: 10.1016/j.conbuildmat.2018.09.054 [12] Pavlík V, Užáková M. Effect of curing conditions on the properties of lime, lime-metakaolin and lime-zeolite mortars[J]. Construction and Building Materials, 2016, 102: 14-25. doi: 10.1016/j.conbuildmat.2015.10.128 [13] Azerêdo A, Azeredo G, Carneiro A. Study of rheological parameters of lime-metakaolin paste made of Kaolin wastes and lime paste[J]. Key Eng Mater, 2015, 668: 419-432. doi: 10.4028/www.scientific.net/KEM.668.419 [14] Zhang D J, Zhao J H, Wang D M, et al. Influence of pozzolanic materials on the properties of natural hydraulic lime based mortars[J]. Construction and Building Materials, 2020, 244: 118360. doi: 10.1016/j.conbuildmat.2020.118360 [15] Xu S Q, Wang J L, Ma Q L, et al. Study on the lightweight hydraulic mortars designed by the use of diatomite as partial replacement of natural hydraulic lime and masonry waste as aggregate[J]. Construction and Building Materials, 2014, 73: 33-40. doi: 10.1016/j.conbuildmat.2014.09.062 [16] Bras A, Henriques F M A, Cidade M T. Effect of environmental temperature and fly ash addition in hydraulic lime grout behaviour[J]. Construction and Building Materials, 2010, 24(8): 1511-1517. doi: 10.1016/j.conbuildmat.2010.02.001 [17] 张芳, 温超凯, 张林, 等. 矿粉对水泥和混凝土性能的影响[J]. 武汉工程大学学报, 2013, 35(11): 43-48. https://www.cnki.com.cn/Article/CJFDTOTAL-WHHG201311010.htmZhang Fang, Wen Chaokai, Zhang Lin, et al. Effect of slag powder on properties of concrete and cement[J]. Journal of Wuhan Institute of Technology, 2013, 35(11): 43-48. https://www.cnki.com.cn/Article/CJFDTOTAL-WHHG201311010.htm [18] 李亚刚, 廖宜顺, 刘艳玲, 等. 超细矿渣粉和偏高岭土对硫铝酸盐水泥水化和强度的影响[J]. 硅酸盐通报, 2021, 40(5): 1586-1593, 1609. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202105021.htmLi Yagang, Liao Yishun, Liu Yanling, et al. Effects of ultrafine ground granulated blast furnace slag and metakaolin on hydration and strength of calcium sulfoaluminate cement[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(5): 1586-1593, 1609. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202105021.htm [19] Chen W, Brouwers H J H. The hydration of slag, part 2: reaction models for blended cement[J]. Journal of Materials Science, 2007, 42(2): 444-464. doi: 10.1007/s10853-006-0874-1 [20] Liu Z Y, Ni W, Li Y, et al. The mechanism of hydration reaction of granulated blast furnace slag-steel slag-refining slag-desulfurization gypsum-based clinker-free cementitious materials[J]. Journal of Building Engineering, 2021, 44: 103289. doi: 10.1016/j.jobe.2021.103289 [21] Moropoulou A, Bakolas A, Bisbikou K. Investigation of the technology of historic mortars[J]. Journal of Cultural Heritage, 2000, 1(1): 45-58. doi: 10.1016/S1296-2074(99)00118-1 [22] 吴中伟, 廉慧珍. 高性能混凝土[M]. 北京: 中国铁道出版社, 1999: 24. -

下载:

下载: