A performance study of hydrophobically modified coal gangue mortar

-

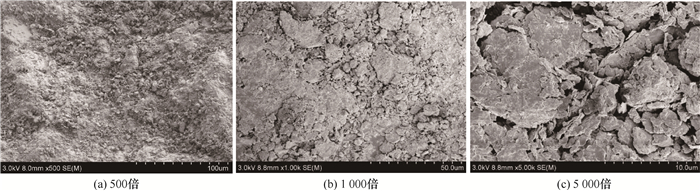

摘要: 煤矸石物理化学特性复杂、强度低、疏松多孔的特点,限制了其在建筑材料中的大量使用。本文采用疏水溶液浸泡的方式,在非煅烧、非预湿的条件下对煤矸石进行了改性。在系统研究改性前后煤矸石基本性质的基础上,设置0%、30%、50%、70%和100%共5种疏水改性后煤矸石质量替代率,以接触角、抗折强度、抗压强度、氯离子电通量为表征参数,分析了不同疏水改性煤矸石替代率对砂浆性能的影响。研究结果表明:采用本文的制备方法,当改性煤矸石替代率低于50%时,可实现煤矸石砂浆表面的疏水状态;抗压强度随改性煤矸石替代率的增大呈现降低的趋势,最大降低率为不掺加改性煤矸石时的15.7%;替代率为30%时,28 d抗压强度为58.5 MPa。不同改性煤矸石替代率下砂浆电通量均小于250 C,表现出优秀的抗氯离子渗透性。替代率为30%时电通量最小,为130 C。采用本研究提出的疏水改性的方法,可以使煤矸石在非煅烧、非预湿的条件下,保证砂浆良好的力学强度和抗氯离子渗透性能,实现煤矸石的充分利用。Abstract: Coal gangue has the characteristics of complex physical and chemical properties, low strength, loose and porous, which limit its extensive use in building materials. In this paper, coal gangue was modified by soaking in hydrophobic solution under uncalcining and non-prewetting conditions. The basic characteristics of coal gangue before and after modification was systematically studied, and hydrophobically modified coal gangue mass substitution rates of 0%, 30%, 50%, 70% and 100% were set. Contact angel, flexural strength, compressive strength, electric flux were used as characteristic parameters to evaluate the influence of modified coal gangue replacement rate on the basic properties of mortar under different substitution rates.Results showed that, by using the binary cooperative complementary method, when the replacement rate of modified coal gangue was lss than 50%, the hydrophobic state of the surface of coal gangue mortar could be achieved. As the replacement rate of modified coal gangue increases, the compressive strength showed a decreasing trend, the maximum decrease was 15.7% compared with none modified coal gangue added. The 28 d compressive strength was 58.5 MPa with 30% replacement rate of modified coal gangue. The electric flux was less than 250 C under different modified coal gangue replacement rate, which indicated excellent resistance to chloride permeability. When the modified coal gangue replacement rate is 30%, the electric flux was the smallest (130 C). The hydrophobic modification method could ensure good mechanical strength and resistance to chloride penetration under the condition of uncalcined and non-prewetted coal gangue, which fully utilizes coal gangue.

-

Key words:

- coal gangue /

- hydrophobic modification /

- contact angle /

- chloride permeability /

- mortar

-

表 1 煤矸石细骨料的压碎指标

Table 1. The crush index of coal gangue fine aggregates

编号 粒级/mm 压碎指标实测值/% 平均值/% CCG 0.60~1.18 20 20 20 20 FCG 0.30~0.60 21 23 25 21 表 2 骨料的堆积密度和表观密度

Table 2. The bulk density and apparent density of aggregates

编号 疏水处理 堆积密度/(kg·m-3) 表观密度/(kg·m-3) CQS 未处理 1 328 2 628 FQS 1 337 2 629 CCG 1 234 2 307 FCG 1 246 2 442 HTCCG 处理后 1 054 2 093 HTFCG 1 086 1 866 表 3 砂浆配合比

Table 3. Mix proportion of mortar

试样名称 水泥/g 硅灰/g 疏水溶液/g 煤矸石/g 替代率/% 石英砂/g PCA/g 粗 细 粗 细 CGM0 650 32.5 136.5 0 0 0 364.0 182.0 17.2 CGM30 650 32.5 136.5 109.2 54.6 30 254.8 127.4 19.6 CGM50 650 32.5 136.5 182.0 91.0 50 182.0 91.0 22.2 CGM70 650 32.5 136.5 254.8 127.4 70 109.2 54.6 23.8 CGM100 650 32.5 136.5 364.0 182.0 100 0 0 25.4 -

[1] Li J Y, Wang J M. Comprehensive utilization and environmental risks of coal gangue: a review[J]. Journal of Cleaner Production, 2019, 239: 117946. doi: 10.1016/j.jclepro.2019.117946 [2] Liu H B, Liu Z L. Recycling utilization patterns of coal mining in China[J]. Resources, Conservation and Recycling, 2010, 54: 1331-1340. doi: 10.1016/j.resconrec.2010.05.005 [3] Mohammed A, Mudavath H, Arif A B M. Characte-rization studies on coal gangue for sustainable geotechnics[J]. Innovative Infrastructure Solutions, 2020, 5: 15. doi: 10.1007/s41062-020-0267-3 [4] 葛林瀚, 杜慧, 周春侠. 煤矸石的危害性及其资源化利用进展[J]. 煤炭技术, 2010, 29(7): 9-11. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201007005.htmGe Linhan, Du Hui, Zhou Chunxia. Harmfulness of coal gangue and it's recycling utilization and development trend[J]. Coal Technology, 2010, 29(7): 9-11. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201007005.htm [5] Gao Y J, Huang H J, Tang W J, et al. Preparation and characterization of a novel porous silicate material from coal gangue[J]. Microporous and Mesoporous Materials, 2015, 217: 210-218. doi: 10.1016/j.micromeso.2015.06.033 [6] 国家发展和改革委员会. 中国资源综合利用年度报告[J]. 再生资源与循环经济, 2014, 7(10): 3-8. doi: 10.3969/j.issn.1674-0912.2014.10.003National Development and Reform Commission. Annual report on comprehensive utilization of resources in China[J]. Renewable Resources and Circular Economy, 2014, 7(10): 3-8. doi: 10.3969/j.issn.1674-0912.2014.10.003 [7] 李少伟, 周梅, 张莉敏. 自燃煤矸石粗骨料特性及其对混凝土性能的影响[J]. 建筑材料学报, 2020, 23(2): 334-340. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX202002016.htmLi Shaowei, Zhou Mei, Zhang Limin. Properties of spontaneous combustion coal gangue coarse aggregate and its influence on concrete[J]. Journal of Building Materials, 2020, 23(2): 334-340. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX202002016.htm [8] 崔正龙, 郝敬力, 陈龙, 等. 自燃煤矸石混凝土强度及干燥收缩裂缝试验研究[J]. 非金属矿, 2015, 38(6): 76-78. doi: 10.3969/j.issn.1000-8098.2015.06.023Cui Zhenglong, Hao Jingli, Chen Long, et al. Experimental study on strength and drying shrinkage crack of spontaneous combustion gangue concrete[J]. Non-Metallic Mines, 2015, 38(6): 76-78. doi: 10.3969/j.issn.1000-8098.2015.06.023 [9] 李永靖, 曹爽, 邢洋, 等. 煤矸石骨料混凝土的干燥收缩性能试验研究[J]. 混凝土, 2016, 11: 95-97. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201611025.htmLi Yongjing, Cao Shuang, Xing Yang, et al. Experimental study on the drying shrinkage performance of the concrete w ith coal gangue aggregate[J]. Concrete, 2016, 11: 95-97. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201611025.htm [10] 王爱国, 朱愿愿, 徐海燕, 等. 混凝土用煤矸石骨料的研究进展[J]. 硅酸盐通报, 2019, 38(7): 2076-2086. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201907017.htmWang Aiguo, Zhu Yuanyuan, Xu Haiyan, et al. Research progress on coal gangue aggregate for concrete[J]. Bulletin of thr Chinese Ceramic Society, 2019, 38(7): 2076-2086. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201907017.htm [11] 田雷, 邱流潮. (超)疏水水泥基材料的研究进展[J]. 材料导报, 2021, 35(19): 19070-19080. doi: 10.11896/cldb.20070002Tian Lei, Qiu Liuchao. Progress of (super) hydrophobic cement-based materials[J]. Materials Report, 2021, 35(19): 19070-19080. doi: 10.11896/cldb.20070002 [12] 冯新军, 陈旺, 李旺. 硅烷偶联剂改性煤矸石粉沥青胶浆路用性能及改性机理[J]. 2020, 23(5): 1121-1129.Feng Xinjun, Chen Wang, Li Wang. Road performance and modification mechanism of coal gangue powder asphalt mortar modified with silane coupling agent[J]. Journal of Building Materials, 2020, 23(5): 1121-1129. [13] Song J L, Zhao D Y, Han Z J, et al. Super-robust superhydrophobic concrete[J]. Journal of Materials Chemistry A, 2017, 5, 14542. doi: 10.1039/C7TA03526H [14] Song J L, Li Y X, Xu W, et al. Inexpensive and non-fluorinated superhydrophobic concrete coating for anti-icing and anti-corrosion[J]. Journal of Colloid and Interface Science, 2019, 541: 86-92. doi: 10.1016/j.jcis.2019.01.014 [15] 程温卿, 王少杰, 刘福胜, 等. 煤矸石用作植被混凝土粗骨料的简化分级方法研究[J]. 新型建筑材料, 2017, 11: 48-50. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201711017.htmCheng Wenqing, Wang Shaojie, Liu Fusheng, et al. Study on simplified classification method of coal gangue used as vegetation concrete coarse aggregate[J]. New Building Materials, 2017, 11: 48-50. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201711017.htm [16] 江雷. 从自然到仿生的超疏水纳米界面材料[J]. 科技导报, 2005, 23(2): 4-8. doi: 10.3321/j.issn:1000-7857.2005.02.002Jiang Lei. Super-hydrophobic nanoscale interface materials: from natural to artificial[J]. Science & Technology Review, 2005, 23(2): 4-8. doi: 10.3321/j.issn:1000-7857.2005.02.002 [17] 邱继生, 侯博雯, 关虓, 等. 煤矸石理化性质对混凝土抗压强度的影响[J]. 非金属矿, 2019, 42(2): 29-32. doi: 10.3969/j.issn.1000-8098.2019.02.008Qiu Jisheng, Hou Bowen, Guan Xiao, et al. Effect of physical and chemical properties of coal gangue under different stratas on compressive strength of concrete[J]. Non-Metallic Mines, 2019, 42(2): 29-32. doi: 10.3969/j.issn.1000-8098.2019.02.008 [18] 施惠生, 施韬, 陈宝春, 等. 掺矿渣活性粉末混凝土的抗氯离子渗透性研究[J]. 同济大学学报(自然科学版), 2006, 34(1): 93-96. doi: 10.3321/j.issn:0253-374X.2006.01.019Shi Huisheng, Shi Tao, Chen Baochun, et al. Research of chloride ion diffusivity in reactive powder concrete with blast-furnace slag[J]. Journal of Tongji Universit: Natural Science, 2006, 34(1): 93-96. doi: 10.3321/j.issn:0253-374X.2006.01.019 [19] 马宏强, 易成, 朱红光, 等. 煤矸石集料混凝土抗压强度及耐久性能[J]. 材料导报B: 研究篇, 2018, 32(7): 2390-2395. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201814013.htmMa Hongqiang, Yi Cheng, Zhou Honguang, et al. Compressive strength and durability of coal gangue aggregate concrete[J]. Materials Reports B, 2018, 32(7): 2390-2395. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201814013.htm [20] 李永靖, 岳玮琦, 潘铖, 等. 表面活化煤矸石集料水泥砂浆性能试验研究[J]. 非金属矿, 2017, 40(6): 36-38. https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK201706011.htmLi Yongjing, Yue Weiqi, Pan Cheng, et al. Performance study of surface activated coal gangue aggregate cement mortar[J]. Non-Metallic Mines, 2017, 40(6): 36-38. https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK201706011.htm [21] Wang A G, Liu P, Mo L W, et al. Mechanism of thermal activation on granular coal gangue and its impact on the performance of cement mortars[J]. Journal of Building Engineering, 2022, 45: 103616. doi: 10.1016/j.jobe.2021.103616 [22] 周梅, 田博宇, 王强, 等. 自燃煤矸石粗集料对砂轻混凝土性能影响的试验研究[J]. 硅酸盐通报2013, 32(11): 2231-2237. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201311014.htmZhou Mei, Tian Boyu, Wang Qiang, et al. Experimental study on the influence of spontaneous combustion gangue coarse aggregate on sand lightweight concrete performance[J]. Bulletin of thr Chinese Ceramic Society, 2013, 32(11): 2231-2237. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201311014.htm [23] Yu P, Kirkpatrick R J, Poe B, et al. Structure of calcium silicate hydrate (C-S-H): Near-, Mid-, and Far- infrared spectroscopy[J]. Journal of the American Ceramic Society, 1999, 82(3): 742-748. -

下载:

下载: