Research progress on recycling technologies of lithium-ion batteries from electric vehicles

-

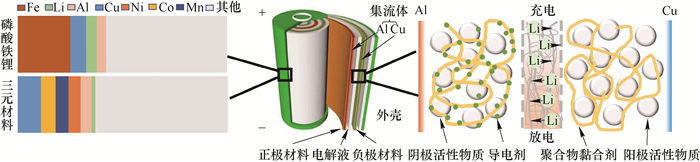

摘要: 新能源汽车行业的迅猛发展,带动了动力锂离子电池需求量的激增,使得天然的钴、锂、镍等成为稀缺资源。为推动新能源汽车产业的持续健康发展,解决锂离子电池带来的环境污染和资源匮乏问题,实现锂离子电池的绿色循环利用迫在眉睫。本文围绕退役动力锂离子电池放电、拆解、剥离、分选、冶金等作业环节,对其循环回收过程进行了系统评述。从技术研发与工业应用多角度分析了不同作业方式对剥离、分选、冶金等效果的影响,讨论了各作业环节的研究进展和存在的主要问题,展望了退役动力锂离子电池循环回收行业未来发展方向,为退役动力锂离子电池绿色高效循环利用提供了重要依据。Abstract: The rapid development of the electric vehicle industry has led to a surge in demand for power lithium-ion batteries, making natural cobalt, lithium, and nickel scarce mineral resources. To promote the sustainable development of the electric vehicle industry and solve the problems of environmental pollution as well as resource scarcity caused by lithium-ion batteries, it is extremely imperative to realize the green recycling of end-of-life electric vehicle lithium-ion batteries. This article systematically reviewed and evaluated the recycling process of lithium-ion batteries from electric vehicles, which focuses on discharging, dismantling, stripping, separation, metallurgy and other operations. The influence of different operation methods on stripping, sorting, metallurgy and other effects is analyzed from the perspectives of technology research and development and industrial application, and the research progress and main problems of each operation link are discussed. The future development of recycling lithium-ion batteries is prospected, which lay the foundation for the green and efficient recycling of spent lithium-ion batteries.

-

Key words:

- spent power lithium-ion batteries /

- recycling /

- striping /

- separation methods /

- metallurgy

-

表 1 不同剥离方法效果比较

Table 1. Comparison of stripping performance of various methods

剥离方式 实验方法 实验条件 电极粉剥离效果/% 物理法 超声剥离[22] 55 ℃水浴,10 min 92.00 机械剥离[27] -38 ℃预处理5 min,研磨0.5 min 87.29 化学法 高温煅烧[29] 甲烷,500 ℃高温煅烧,300 min 98.00 真空热解[28] 450 ℃真空热解,60 min 99.50 碱溶[32] 32 g/L NaOH,10 min 98.00 NMP溶解[21] 70 ℃超声,90 min 98.72 磷酸三乙酯溶解[34] 100 ℃搅拌,60 min 92.00 柑橘类果汁溶解[35] 90 ℃搅拌,20 min 94.00 硫酸溶解[36] 40 ℃超声、搅拌,5 min 99.00 表 2 正、负极粉末分选方法

Table 2. Separation methods of anode and cathode powders

表 3 有价金属的冶金回收方法

Table 3. Metallurgical recovery methods of valuable metals

冶金方法 电池类型 实验条件 回收率/% 火法[52-54] NCM 正极石墨,3 h,600 ℃ Li=99,Ni=99,Co=99,Mn=97 NCM 硫酸钴,2 h,800 ℃ Li=80 NCM 炭黑,0.5 h,550 ℃ Li=99,Ni=99.58,Mn=99.99 湿法[55-67] NCA 盐酸,18 h,25 ℃,50 g/L Ni=99.99,Co=100 NCM 硝酸,盐酸,1 h,80 ℃,50 g/L Li=100,Mn=99 NCM 硫酸,过氧化氢,1 h,40 ℃,40 g/L Li=99.7,Ni=99.7,Co=99.7 NCM 甲酸,过氧化氢,2 h,60 ℃,50 g/L Li=98.22,Ni=99.96,Co=99.96 NCM 乙酸,抗坏血酸,甘蔗渣髓0.6 h,50 ℃,20 g/L Li=91.6,Ni=93.5,Co=93.6 NCM 马来酸,过氧化氢,1 h,70 ℃,40 g/L Li=98.24,Ni=98.41,Co=98.05 NCM 氨水,亚硫酸铵,2 h,25 ℃ Ni=97.7,Co=99.1 NCM 氨水,亚硫酸钠,8 h,80 ℃,50 g/L Li=95.3,Ni=89.8,Co=80.7 NCM 氨水,炭黑,6 h,30 ℃,150 g/L Li=76.19,Ni=96.23,Co=94.57 NCM 氧化亚铁硫杆菌,72 h,30 ℃,100 g/L Li=76.19,Ni=96.23,Co=94.57 NCM 嗜铁钩端螺旋体,216 h,30 ℃,100 g/L Li=97,Co=96 NCM 胞外聚合物,24 h,30 ℃ Ni=55.2,Co=44.9 -

[1] Chen M Y, Ma X T, Chen B, et al. Recycling end-of-life electric vehicle lithium-ion batteries[J]. Joule, 2019, 3(11): 2622-2646. doi: 10.1016/j.joule.2019.09.014 [2] Harper G, Sommerville R, Kendrick E, et al. Recycling lithium-ion batteries from electric vehicles[J]. Nature, 2019, 575(7781): 75-86. doi: 10.1038/s41586-019-1682-5 [3] Haram M H S M, Lee J W, Ramasamy G, et al. Feasibility of utilising second life EV batteries: Applications, lifespan, economics, environmental impact, assessment, and challenges[J]. Alexandria Engineering Journal, 2021, 60(5): 4517-4536. doi: 10.1016/j.aej.2021.03.021 [4] Horesh N, Quinn C, Wang H, et al. Driving to the future of energy storage: Techno-economic analysis of a novel method to recondition second life electric vehicle batteries[J]. Applied Energy, 2021, 295: 117007. doi: 10.1016/j.apenergy.2021.117007 [5] Makuza B, Tian Q H, Guo X Y, et al. Pyrometallurgical options for recycling spent lithium-ion batteries: a comprehensive review[J]. Journal of Power Sources, 2021, 491: 229622. doi: 10.1016/j.jpowsour.2021.229622 [6] Nan J M, Han D M, Yang M J, et al. Recovery of metal values from a mixture of spent lithium-ion batteries and nickel-metal hydride batteries[J]. Hydrometallurgy, 2006, 84(1/2): 75-80. [7] Arshad F, Li L, Amin K, et al. A comprehensive review of the advancement in recycling the anode and electrolyte from spent lithium ion batteries[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(36): 13527-13554. [8] Zhang G W, Yuan X, He Y Q, et al. Recent advances in pretreating technology for recycling valuable metals from spent lithium-ion batteries[J]. Journal of Hazardous Materials, 2021, 406: 124332. doi: 10.1016/j.jhazmat.2020.124332 [9] Xiao J F, Guo J, Zhan L, et al. A cleaner approach to the discharge process of spent lithium ion batteries in different solutions[J]. Journal of Cleaner Production, 2020, 255: 120064. doi: 10.1016/j.jclepro.2020.120064 [10] Ojanen S, Lundström M, Santasalo-Aarnio A, et al. Challenging the concept of electrochemical discharge using salt solutions for lithium-ion batteries recycling[J]. Waste Management, 2018, 76: 242-249. doi: 10.1016/j.wasman.2018.03.045 [11] 杨瑞鑫, 熊瑞, 孙逢春. 锂离子动力电池外部短路测试平台开发与试验分析[J]. 电气工程学报, 2021, 16(1): 103-118. https://www.cnki.com.cn/Article/CJFDTOTAL-DQZH202101014.htmYang Ruixin, Xiong Rui, Sun Fengchun. Experimental platform development and characteristics analysis of external short circuit in lithium-ion batteries[J]. Journal of Electrical Engineering, 2021, 16(1): 103-118. https://www.cnki.com.cn/Article/CJFDTOTAL-DQZH202101014.htm [12] Zhong X H, Liu W, Han J W, et al. Pretreatment for the recovery of spent lithium ion batteries: theoretical and practical aspects[J]. Journal of Cleaner Production, 2020, 263: 121439. doi: 10.1016/j.jclepro.2020.121439 [13] Wegener K, Chen W H, Dietrich F, et al. Robot assisted disassembly for the recycling of electric vehicle batteries[J]. Procedia CIRP, 2015, 29: 716-721. doi: 10.1016/j.procir.2015.02.051 [14] Choux M, Marti Bigorra E, Tyapin I. Task planner for robotic disassembly of electric vehicle battery pack[J]. Metals, 2021, 11(3): 387. doi: 10.3390/met11030387 [15] Li L R, Zheng P N, Yang T R, et al. Disassembly automation for recycling end-of-life lithium-ion pouch cells[J]. JOM, 2019, 71(12): 4457-4464. doi: 10.1007/s11837-019-03778-0 [16] Ku H, Jung Y, Jo M, et al. Recycling of spent lithium-ion battery cathode materials by ammoniacal leaching[J]. Journal of Hazardous Materials, 2016, 313: 138-146. doi: 10.1016/j.jhazmat.2016.03.062 [17] Porvali A, Aaltonen M, Ojanen S, et al. Mechanical and hydrometallurgical processes in HCl media for the recycling of valuable metals from Li-ion battery waste[J]. Resources Conservation and Recycling, 2019, 142: 257-266. doi: 10.1016/j.resconrec.2018.11.023 [18] Zhang T, He Y Q, Ge L H, et al. Characteristics of wet and dry crushing methods in the recycling process of spent lithium-ion batteries[J]. Journal of Power Sources, 2013, 240: 766-771. doi: 10.1016/j.jpowsour.2013.05.009 [19] Muhammad A, Sales W F. Iron-graphene based anode material for rechargeable lithium-ion batteries decorated by gold nanoparticles recovered from gold plated waste surgical tools[J]. Surfaces and Interfaces, 2021, 27: 101575. doi: 10.1016/j.surfin.2021.101575 [20] Kim S, Bang J, Yoo J, et al. A comprehensive review on the pretreatment process in lithium-ion battery recycling[J]. Journal of Cleaner Production, 2021, 294: 126329. doi: 10.1016/j.jclepro.2021.126329 [21] He L P, Sun S Y, Song X F, et al. Recovery of cathode materials and Al from spent lithium-ion batteries by ultrasonic cleaning[J]. Waste Management, 2015, 46: 523-528. doi: 10.1016/j.wasman.2015.08.035 [22] Li J H, Shi P X, Wang Z F, et al. A combined recovery process of metals in spent lithium-ion batteries[J]. Chemosphere, 2009, 77(8): 1132-1136. doi: 10.1016/j.chemosphere.2009.08.040 [23] Zhang T, He Y Q, Wang F F, et al. Chemical and process mineralogical characterizations of spent lithium-ion batteries: an approach by multi-analytical techniques[J]. Waste Management, 2014, 34(6): 1051-1058. doi: 10.1016/j.wasman.2014.01.002 [24] Ebin B, Petranikova M, Ekberg C. Physical separation, mechanical enrichment and recycling-oriented characterization of spent NiMH batteries[J]. Journal of Material Cycles and Waste Management, 2018, 20(4): 2018-2027. doi: 10.1007/s10163-018-0751-4 [25] Shin S M, Kim N H, Sohn J S, et al. Development of a metal recovery process from Li-ion battery wastes[J]. Hydrometallurgy, 2005, 79(3/4): 172-181. [26] Zhang T, He Y Q, Ge L H, et al. Characteristics of wet and dry crushing methods in the recycling process of spent lithium-ion batteries[J]. Journal of Power Sources, 2013, 240: 766-771. doi: 10.1016/j.jpowsour.2013.05.009 [27] Wang H F, Liu J S, Bai X J, et al. Separation of the cathode materials from the Al foil in spent lithium-ion batteries by cryogenic grinding[J]. Waste Management, 2019, 91: 89-98. doi: 10.1016/j.wasman.2019.04.058 [28] Tao R, Xing P, Li H Q, et al. Full-component pyrolysis coupled with reduction of cathode material for recovery of spent LiNixCoyMnzO2 lithium-ion batteries[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(18): 6318-6328. [29] Yang C, Zhang J L, Yu B Y, et al. Recovery of valuable metals from spent LiNixCoyMnzO2 cathode material via phase transformation and stepwise leaching[J]. Separation and Purification Technology, 2021, 267: 118609. doi: 10.1016/j.seppur.2021.118609 [30] Sun L, Qiu K Q. Vacuum pyrolysis and hydrometallurgical process for the recovery of valuable metals from spent lithium-ion batteries[J]. Journal of Hazardous Materials, 2011, 194: 378-384. doi: 10.1016/j.jhazmat.2011.07.114 [31] Lombardo G, Ebin B, Steenari B M, et al. Comparison of the effects of incineration, vacuum pyrolysis and dynamic pyrolysis on the composition of NMC-lithium battery cathode-material production scraps and separation of the current collector[J]. Resources, Conservation and Recycling, 2021, 164: 105142. doi: 10.1016/j.resconrec.2020.105142 [32] Ferreira D A, Prados L M Z, Majuste D, et al. Hydrometallurgical separation of aluminium, cobalt, copper and lithium from spent Li-ion batteries[J]. Journal of Power Sources, 2009, 187(1): 238-246. doi: 10.1016/j.jpowsour.2008.10.077 [33] Larouche F, Tedjar F, Amouzegar K, et al. Progress and status of hydrometallurgical and direct recycling of Li-ion batteries and beyond[J]. Materials: Basel, Switzerland, 2020, 13(3): 801. [34] Bai Y C, Essehli R, Jafta C J, et al. Recovery of cathode materials and aluminum foil using a green solvent[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(17): 6048-6055. [35] Pant D, Dolker T. Green and facile method for the recovery of spent Lithium Nickel Manganese Cobalt Oxide (NMC) based Lithium ion batteries[J]. Waste Management, 2017, 60: 689-695. doi: 10.1016/j.wasman.2016.09.039 [36] Chen X P, Li S Z, Wu X, et al. In-situ recycling of coating materials and Al foils from spent lithium ion batteries by ultrasonic-assisted acid scrubbing[J]. Journal of Cleaner Production, 2020, 258: 120943. doi: 10.1016/j.jclepro.2020.120943 [37] Sommerville R, Shaw-Stewart J, Goodship V, et al. A review of physical processes used in the safe recycling of lithium ion batteries[J]. Sustainable Materials and Technologies, 2020, 25: e00197. doi: 10.1016/j.susmat.2020.e00197 [38] Zhang G W, He Y Q, Wang H F, et al. Removal of organics by pyrolysis for enhancing liberation and flotation behavior of electrode materials derived from spent lithium-ion batteries[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(5): 2205-2214. [39] Silveira A V M, Santana M P, Tanabe E H, et al. Recovery of valuable materials from spent lithium-ion batteries using electrostatic separation[J]. International Journal of Mineral Processing, 2017, 169: 91-98. doi: 10.1016/j.minpro.2017.11.003 [40] Shin S M, Kim N H, Sohn J S, et al. Development of a metal recovery process from Li-ion battery wastes[J]. Hydrometallurgy, 2005, 79(3/4): 172-181. [41] Marinos D, Mishra B. An approach to processing of lithium-ion batteries for the zero-waste recovery of materials[J]. Journal of Sustainable Metallurgy, 2015, 1(4): 263-274. doi: 10.1007/s40831-015-0024-6 [42] Bi H J, Zhu H B, Zu L, et al. Eddy current separation for recovering aluminium and lithium-ion phosphate components of spent lithium-iron phosphate batteries[J]. Waste Management & Research, 2019, 37(12): 1217-1228. [43] Bi H J, Zhu H B, Zu L, et al. A new model of trajectory in eddy current separation for recovering spent lithium-iron phosphate batteries[J]. Waste Management, 2019, 100: 1-9. doi: 10.1016/j.wasman.2019.08.041 [44] Zhu X S, Zhang C Y, Feng P, et al. A novel pulsated pneumatic separation with variable-diameter structure and its application in the recycling spent lithium-ion batteries[J]. Waste Management, 2021, 131: 20-30. doi: 10.1016/j.wasman.2021.05.027 [45] Bi H J, Zhu H B, Zu L, et al. Pneumatic separation and recycling of anode and cathode materials from spent lithium iron phosphate batteries[J]. Waste Management & Research, 2019, 37(4): 374-385. [46] Zhang Y, He Y Q, Zhang T, et al. Application of Falcon centrifuge in the recycling of electrode materials from spent lithium ion batteries[J]. Journal of Cleaner Production, 2018, 202: 736-747. doi: 10.1016/j.jclepro.2018.08.133 [47] Huang Y F, Han G H, Liu J T, et al. A stepwise recovery of metals from hybrid cathodes of spent Li-ion batteries with leaching-flotation-precipitation process[J]. Journal of Power Sources, 2016, 325: 555-564. doi: 10.1016/j.jpowsour.2016.06.072 [48] He Y Q, Zhang T, Wang F F, et al. Recovery of LiCoO2 and graphite from spent lithium-ion batteries by Fenton reagent-assisted flotation[J]. Journal of Cleaner Production, 2017, 143: 319-325. doi: 10.1016/j.jclepro.2016.12.106 [49] Yu J D, He Y Q, Ge Z Z, et al. A promising physical method for recovery of LiCoO2 and graphite from spent lithium-ion batteries: Grinding flotation[J]. Separation and Purification Technology, 2018, 190: 45-52. doi: 10.1016/j.seppur.2017.08.049 [50] Zhao C X, Zhong X H. RETRACTED: Reverse flotation process for the recovery of pyrolytic LiFePO4[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2020, 596: 124741. doi: 10.1016/j.colsurfa.2020.124741 [51] Tang Y Q, Xie H W, Zhang B L, et al. Recovery and regeneration of LiCoO2-based spent lithium-ion batteries by a carbothermic reduction vacuum pyrolysis approach: controlling the recovery of CoO or Co[J]. Waste Management, 2019, 97: 140-148. doi: 10.1016/j.wasman.2019.08.004 [52] Zhang Y C, Wang W Q, Fang Q, et al. Improved recovery of valuable metals from spent lithium-ion batteries by efficient reduction roasting and facile acid leaching[J]. Waste Management, 2020, 102: 847-855. doi: 10.1016/j.wasman.2019.11.045 [53] Lin J, Li L, Fan E S, et al. Conversion mechanisms of selective extraction of lithium from spent lithium-ion batteries by sulfation roasting[J]. ACS Applied Materials & Interfaces, 2020, 12(16): 18482-18489. [54] Liu P C, Xiao L, Chen Y F, et al. Recovering valuable metals from LiNixCoyMn1-x-yO2 cathode materials of spent lithium ion batteries via a combination of reduction roasting and stepwise leaching[J]. Journal of Alloys and Compounds, 2019, 783: 743-752. doi: 10.1016/j.jallcom.2018.12.226 [55] Joulié M, Laucournet R, Billy E. Hydrometallurgical process for the recovery of high value metals from spent lithium nickel cobalt aluminum oxide based lithium-ion batteries[J]. Journal of Power Sources, 2014, 247: 551-555. doi: 10.1016/j.jpowsour.2013.08.128 [56] Castillo S, Ansart F, Laberty-Robert C, et al. Advances in the recovering of spent lithium battery compounds[J]. Journal of Power Sources, 2002, 112(1): 247-254. doi: 10.1016/S0378-7753(02)00361-0 [57] He L P, Sun S Y, Song X F, et al. Leaching process for recovering valuable metals from the LiNi1/3Co1/3 Mn1/3O2 cathode of lithium-ion batteries[J]. Waste Management, 2017, 64: 171-181. doi: 10.1016/j.wasman.2017.02.011 [58] Gao W F, Zhang X H, Zheng X H, et al. Lithium carbonate recovery from cathode scrap of spent lithium-ion battery: a closed-loop process[J]. Environmental Science & Technology, 2017, 51(3): 1662-1669. [59] Yan S X, Sun C H, Zhou T, et al. Ultrasonic-assisted leaching of valuable metals from spent lithium-ion batteries using organic additives[J]. Separation and Purification Technology, 2021, 257: 117930. doi: 10.1016/j.seppur.2020.117930 [60] Golmohammadzadeh R, Rashchi F, Vahidi E. Recovery of lithium and cobalt from spent lithium-ion batteries using organic acids: process optimization and kinetic aspects[J]. Waste Management, 2017, 64: 244-254. doi: 10.1016/j.wasman.2017.03.037 [61] Ma Y Y, Tang J J, Wanaldi R, et al. A promising selective recovery process of valuable metals from spent lithium ion batteries via reduction roasting and ammonia leaching[J]. Journal of Hazardous Materials, 2021, 402: 123491. doi: 10.1016/j.jhazmat.2020.123491 [62] Zheng X H, Gao W F, Zhang X H, et al. Spent lithium-ion battery recycling-Reductive ammonia leaching of metals from cathode scrap by sodium sulphite[J]. Waste Management, 2017, 60: 680-688. doi: 10.1016/j.wasman.2016.12.007 [63] Li D M, Zhang B, Ou X, et al. Ammonia leaching mechanism and kinetics of LiCoO2 material from spent lithium-ion batteries[J]. Chinese Chemical Letters, 2021, 32(7): 2333-2337. doi: 10.1016/j.cclet.2020.11.074 [64] Wang H Y, Huang K, Zhang Y, et al. Recovery of lithium, nickel, and cobalt from spent lithium-ion battery powders by selective ammonia leaching and an adsorption separation system[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(12): 11489-11495. [65] Jegan Roy J, Srinivasan M, Cao B. Bioleaching as an eco-friendly approach for metal recovery from spent NMC-based lithium-ion batteries at a high pulp density[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(8): 3060-3069. [66] Xin Y Y, Guo X M, Chen S, et al. Bioleaching of valuable metals Li, Co, Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery[J]. Journal of Cleaner Production, 2016, 116: 249-258. doi: 10.1016/j.jclepro.2016.01.001 [67] Wang J, Tian B Y, Bao Y H, et al. Functional exploration of extracellular polymeric substances (EPS) in the bioleaching of obsolete electric vehicle LiNix CoyMn1-x-yO2 Li-ion batteries[J]. Journal of Hazardous Materials, 2018, 354: 250-257. doi: 10.1016/j.jhazmat.2018.05.009 -

下载:

下载: