The optimization of pervious concrete ratios with spontaneous combustion gangue aggregates based on the RSM-BBD method

-

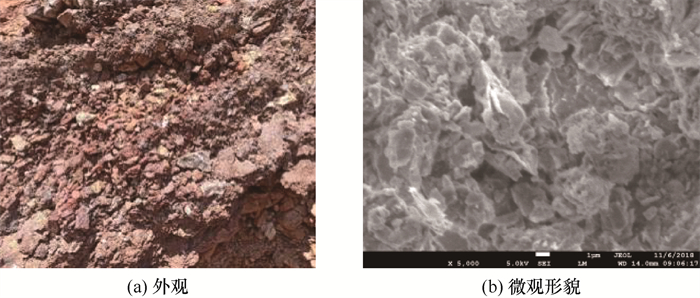

摘要: 为了对自燃煤矸石骨料透水混凝土进行配比优化,采用BBD响应面法设计17组试验,研究骨灰比、水灰比和增强剂掺量对透水混凝土抗压强度、透水系数和孔隙率的影响,构建响应面模型,揭示各因素与响应值的相关关系,获得综合性能最优配比。研究结果表明:各因素与各响应值关系皆呈二次多项式模型,回归系数R2皆大于0.9,说明模型合理性和拟合性较好。水灰比和骨灰比对各响应值影响均非常显著,增强剂掺量只对抗压强度影响非常显著,骨灰比和增强剂掺量交互项对抗压强度影响显著,水灰比与增强剂掺量交互项对孔隙率影响显著。当骨灰比3.2、水灰比0.22、增强剂掺量4.5 % 时,混凝土28 d抗压强度为28.7 MPa、透水系数3.21 mm/s、孔隙率19.7 %,满足C20透水混凝土的工程要求。Abstract: In order to optimize the ratio of pervious concrete with spontaneous combustion coal gangue aggregate, 17 groups of experiments were designed by the BBD response surface method to study the effects of aggregate-cement ratio, water-cement ratio, and reinforcing agent on the compressive strength, permeability coefficient, and porosity of pervious concrete. The response surface model was constructed to reveal the correlation between various factors and response values and obtain the optimal ratio of comprehensive performance. The results show that each factor and each response value are quadratic polynomial models, and the regression coefficient R2 of each model is greater than 0.9, indicating that the model is reasonable and fitting. The influence of water-cement ratio and aggregate-cement ratio on each response value and reinforcing agent on compressive strength is very significant. The influence of the interaction of aggregate-cement ratio and water-cement ratio on compressive strength and the interaction of water-cement ratio and reinforcing agent on porosity is significant. When the ratio of aggregate-cement ratio is 3.2, the ratio of water-cement ratio is 0.22, and the dosage of the reinforcing agent is 4.5 %, the 28 d compressive strength of pervious concrete reaches 28.7 MPa, the permeability coefficient is 3.21 mm/s, and the porosity is 19.7 %, which meets the engineering requirements of C20 pervious concrete.

-

表 1 自燃煤矸石化学组成

Table 1. The chemical composition of spontaneous combustion coal gangue

组成 SiO2 Al2O3 Fe2O3 CaO MgO TiO2 Na2O K2O SO3 质量分数/% 59.34 25.28 4.66 4.50 2.00 1.70 1.15 0.53 0.25 表 2 自燃煤矸石骨料主要技术性质指标

Table 2. Main technical properties of spontaneous combustion coal gangue aggregate

品种 表观密度/(kg·m-3) 松堆密度/(kg·m-3) 压碎指标/% 空隙率/% 吸水率/% 自燃煤矸石 2 382 1 221 18 53.8 9.87 自燃煤矸石细骨料 2 357 1 030 — 56.3 11.70 表 3 设计因素编码及水平

Table 3. Codes and levels of design factors

编码 因素 水平 -1 0 1 x1 mG/mC 2.8 3.1 3.4 x2 mW/mC 0.20 0.22 0.24 x3 wSR/% 3.0 4.5 6.0 表 4 响应面试验设计与结果

Table 4. Design and results of response surface experiment

编号 因素 抗压强度y1/MPa 透水系数y2/(mm·s-1) 孔隙率y3/% mG/mC mW/mC wSR/% 试验值 预测值 试验值 预测值 试验值 预测值 1 2.8 0.24 4.5 41.2 42.0 0.22 0.17 5.8 4.3 2 3.4 0.22 3.0 28.4 29.9 2.31 2.31 18.5 18.3 3 2.8 0.22 3.0 32.4 31.1 0.87 1.00 10.4 11.2 4 3.4 0.22 6.0 32.2 33.5 2.02 1.89 16.3 15.6 5 2.8 0.22 6.0 47.5 46.1 0.58 0.58 8.4 8.6 6 3.4 0.24 4.5 40.5 38.6 0.97 0.72 12.1 11.5 7 2.8 0.20 4.5 26.0 27.9 1.86 2.11 15.4 16.0 8 3.4 0.20 4.5 18.5 17.7 3.45 3.84 21.3 22.8 9 3.1 0.22 4.5 29.8 30.5 1.84 1.72 13.9 14.0 10 3.1 0.22 4.5 29.6 30.5 1.42 1.72 14.2 14.0 11 3.1 0.22 4.5 30.7 30.5 1.62 1.72 12.7 14.0 12 3.1 0.22 4.5 33.0 30.5 1.76 1.72 13.4 14.0 13 3.1 0.22 4.5 29.3 30.5 1.97 1.72 15.7 14.0 14 3.1 0.20 6.0 26.8 26.3 3.87 3.62 21.8 21.0 15 3.1 0.24 6.0 45.2 45.8 1.12 1.50 11.8 13.1 16 3.1 0.24 3.0 34.0 34.5 1.08 1.33 11.4 12.2 17 3.1 0.20 3.0 19.6 19.0 5.00 4.62 28.6 27.3 表 5 抗压强度多种模型综合分析结果

Table 5. Comprehensive analytical results of various models of compressive strength

模型 P值 R2 连续项 失拟项 校正值 预测值 线性模型 < 0.000 1 0.052 7 0.844 7 0.756 2 交互模型 0.180 2 0.065 8 0.873 5 0.678 1 二次模型 0.044 5 0.186 1 0.939 1 0.902 7 表 6 透水系数多种模型综合分析结果

Table 6. Comprehensive analytical results of various models of permeability coefficient

模型 P值 R2 连续项 失拟项 校正值 预测值 线性模型 0.000 3 0.010 6 0.701 1 0.503 8 交互模型 0.808 8 0.006 4 0.645 8 -0.087 1 二次模型 0.007 4 0.050 0 0.909 8 0.905 0 表 7 孔隙率多种模型综合分析结果

Table 7. Comprehensive analysis results of various models of porosity models

模型 P值 R2 连续项 失拟项 校正值 预测值 线性模型 < 0.000 1 0.028 7 0.747 5 0.587 6 交互模型 0.682 5 0.019 3 0.715 5 0.157 3 二次模型 0.006 8 0.158 0 0.922 0 0.905 7 表 8 回归方程的方差分析结果

Table 8. Variance analytical results of regression equation

来源 df 均方差 F值 P值 y1 y2 y3 y1 y2 y3 y1 y2 y3 回归 9 109.03 2.57 51.03 28.39 16.96 22.03 0.000 1 0.000 6 0.000 2 x1 1 94.53 3.41 99.41 24.62 22.49 42.91 0.001 6 0.002 1 0.000 3 x2 1 612.50 14.55 264.50 159.50 96.08 114.16 <0.000 1 <0.000 1 <0.000 1 x3 1 173.91 0.35 14.04 45.29 2.30 6.06 0.000 3 0.173 0 0.053 3 x1 x2 1 11.56 0.18 0.04 3.01 1.16 0.02 0.126 3 0.316 3 0.899 2 x1 x3 1 31.92 0.00 0.00 8.31 0.00 0.00 0.023 5 1.000 0 0.949 5 x2 x3 1 4.00 0.34 12.96 1.04 2.26 5.59 0.341 4 0.176 5 0.048 0 x12 1 24.20 2.12 29.90 6.30 14.00 12.91 0.040 4 0.007 2 0.008 8 x22 1 7.42 1.58 22.96 1.93 10.44 9.91 0.207 1 0.014 4 0.016 2 x32 1 21.27 0.79 18.30 5.54 5.21 7.90 0.020 8 0.056 5 0.026 1 残差 7 3.84 0.15 2.32 — — — — — — 失拟值 3 5.95 0.29 3.74 2.64 6.59 3.00 0.186 1 0.051 0 0.158 0 纯误差 4 2.26 0.05 1.25 — — — — — — 表 9 模型可信度检验分析结果

Table 9. Results of model credibility test and analysis

模型 标准偏差 均值 R2 R2校正值 R2预测值 残差平方和预测值 变异系数/% 信噪比 y1 1.96 32.04 0.973 3 0.939 1 0.902 7 299.75 6.12 18.888 y2 0.39 1.88 0.976 0 0.909 8 0.905 0 14.39 13.7 16.026 y3 1.52 14.81 0.965 9 0.922 0 0.905 7 187.47 10.28 19.702 表 10 参数优化后预测值与实测值对比

Table 10. Comparison of predicted and measured values after parameter optimization

类别 骨灰比 水灰比 增强剂掺量/% 抗压强度 透水系数 孔隙率 预测值/MPa 实测值/MPa 误差/% 预测值/(mm·s-1) 实测值/(mm·s-1) 误差/% 预测值/% 实测值/% 误差/% 实验室试验值 3.2 0.22 4.5 28.7 29.3 2.09 3.21 3.29 2.49 19.7 18.9 4.06 现场试验路段实测值 3.2 0.22 4.5 28.7 30.2 5.23 3.21 3.11 3.12 19.7 19.2 2.54 -

[1] 俞孔坚, 李迪华, 袁弘, 等. "海绵城市"理论与实践[J]. 城市规划, 2015, 39(6): 26-36. https://www.cnki.com.cn/Article/CJFDTOTAL-CSGH201506009.htmYu Kongjian, Li Dihua, Yuan Hong, et al. "Sponge city": theory and practice[J]. City Planning Review, 2015, 39(6): 26-36. https://www.cnki.com.cn/Article/CJFDTOTAL-CSGH201506009.htm [2] 叶强. 工业固废制备透水砖及其孔结构研究进展[J]. 材料导报, 2021, 35(S1): 274-278. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2021S1052.htmYe Qiang. Research progress on the preparation and pore structure characteristics of water-permeable brick by industrial solid waste[J]. Materials Reports, 2021, 35(S1): 274-278. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2021S1052.htm [3] 杨锋. 利用固废材料制备透水混凝土及其性能影响因素研究[D]. 南京: 东南大学, 2020. [4] 王国平. 辽宁阜新煤矸石资源化研究[D]. 成都: 成都理工大学, 2005. [5] Kevern J T, Wang K, Schaefer V R. Effect of coarse aggregate on the freeze-thaw durability of pervious concrete[J]. Journal of Materials in Civil Engineering, 2010, 22(5): 469-475. doi: 10.1061/(ASCE)MT.1943-5533.0000049 [6] Chandrappa A K, Biligiri K P. Pervious concrete as a sustainable pavement material-Research findings and future prospects: a state-of-the-art review[J]. Construction and Building Materials, 2016, 111: 262-274. doi: 10.1016/j.conbuildmat.2016.02.054 [7] 王奕仁, 王栋民. 骨料种类与品质对透水混凝土性能影响的研究进展[J]. 材料导报, 2017, 31(17): 98-105, 121. doi: 10.11896/j.issn.1005-023X.2017.017.014Wang Yiren, Wang Dongmin. Effects of aggregate species and quality on the properties of pervious concrete: a review[J]. Materials Review, 2017, 31(17): 98-105, 121. doi: 10.11896/j.issn.1005-023X.2017.017.014 [8] 李佳彬, 肖建庄, 孙振平. 再生粗骨料特性及其对再生混凝土性能的影响[J]. 建筑材料学报, 2004, 7(4): 390-395. doi: 10.3969/j.issn.1007-9629.2004.04.006Li Jiabin, Xiao Jianzhuang, Sun Zhenping. Properties of recycled coarse aggregate and its influence on recycled concrete[J]. Journal of Building Materials, 2004, 7(4): 390-395. doi: 10.3969/j.issn.1007-9629.2004.04.006 [9] Yang J, Jiang G L. Experimental study on properties of pervious concrete pavement materials[J]. Cement and Concrete Research, 2003, 33(3): 381-386. doi: 10.1016/S0008-8846(02)00966-3 [10] Nguyen D H, Sebaibi N, Boutouil M, et al. A modified method for the design of pervious concrete mix[J]. Construction and Building Materials, 2014, 73: 271-282. doi: 10.1016/j.conbuildmat.2014.09.088 [11] Shu X, Huang B S, Wu H, et al. Performance comparison of laboratory and field produced pervious concrete mixtures[J]. Construction and Building Materials, 2011, 25(8): 3187-3192. doi: 10.1016/j.conbuildmat.2011.03.002 [12] 孙家瑛, 黄科, 蒋华钦. 透水水泥混凝土力学性能和耐久性能研究[J]. 建筑材料学报, 2007, 10(5): 583-587. doi: 10.3969/j.issn.1007-9629.2007.05.016Sun Jiaying, Huang Ke, Jiang Huaqin. Research on physical properties and durability of pervious cement concrete[J]. Journal of Building Materials, 2007, 10(5): 583-587. doi: 10.3969/j.issn.1007-9629.2007.05.016 [13] 高谦, 杨晓炳, 温震江, 等. 基于RSM-BBD的混合骨料充填料浆配比优化[J]. 湖南大学学报: 自然科学版, 2019, 46(6): 47-55. https://www.cnki.com.cn/Article/CJFDTOTAL-HNDX201906007.htmGao Qian, Yang Xiaobing, Wen Zhenjiang, et al. Optimization of proportioning of mixed aggregate filling slurry based on BBD response surface method[J]. Journal of Hunan University: Natural Sciences, 2019, 46(6): 47-55. https://www.cnki.com.cn/Article/CJFDTOTAL-HNDX201906007.htm [14] 李锐, 姜永华, 张燕玲, 等. 基于响应曲面法优化硫酸铵结晶[J]. 硅酸盐学报, 2022, 50(3): 782-790. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB202203022.htmLi Rui, Jiang Yonghua, Zhang Yanling, et al. Optimisation of ammonium sulphate crystallization based on response surface methodology[J]. Journal of the Chinese Ceramic Society, 2022, 50(3): 782-790. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB202203022.htm [15] 刘永鹤, 彭金辉, 孟彬, 等. 莫来石晶须长径比影响因素的响应曲面法优化[J]. 硅酸盐学报, 2011, 39(3): 403-408. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201103006.htmLiu Yonghe, Peng Jinhui, Meng Bin, et al. Parameter optimization for aspect ratio of mullite whiskers by response surface method[J]. Journal of the Chinese Ceramic Society, 2011, 39(3): 403-408. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201103006.htm [16] 李典, 冯国瑞, 郭育霞, 等. 基于响应面法的充填体强度增长规律分析[J]. 煤炭学报, 2016, 41(2): 392-398. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201602016.htmLi Dian, Feng Guorui, Guo Yuxia, et al. Analysis on the strength increase law of filling material based on response surface method[J]. Journal of China Coal Society, 2016, 41(2): 392-398. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201602016.htm [17] 于泽明, 陈艳, 马嵘萍, 等. 动/静荷载作用纤维-矿粉-聚苯乙烯混凝土吸能特征研究[J]. 材料导报, 2021, 35(S2): 669-677. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2021S2124.htmYu Zeming, Chen Yan, Ma Rongping, et al. Study on energy absorption characteristics of BF-SP-EPS concrete under dynamic/static load[J]. Materials Reports, 2021, 35(S2): 669-677. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2021S2124.htm [18] 党星海, 周群, 曹润倬, 等. 采用响应曲面法的补偿收缩混凝土力学性能优化研究[J]. 混凝土, 2019(11): 39-42, 49. doi: 10.3969/j.issn.1002-3550.2019.11.009Dang Xinghai, Zhou Qun, Cao Runzhuo, et al. Study on mechanical properties of shrinkage-compensating concrete by response surface method[J]. Concrete, 2019(11): 39-42, 49. doi: 10.3969/j.issn.1002-3550.2019.11.009 [19] 唐岳松, 张令非, 吕华永. 煤基固废制备充填材料配比优化试验研究[J]. 矿业科学学报, 2019, 4(4): 327-336. http://kykxxb.cumtb.edu.cn/article/id/230Tang Yuesong, Zhang Lingfei, Lü Huayong. Study on proportion optimization of coal-based solid wastes filling materials[J]. Journal of Mining Science and Technology, 2019, 4(4): 327-336. http://kykxxb.cumtb.edu.cn/article/id/230 [20] 周梅, 李高年, 张倩, 等. 自燃煤矸石骨料在预拌混凝土中的应用研究[J]. 建筑材料学报, 2015, 18(5): 830-835. doi: 10.3969/j.issn.1007-9629.2015.05.020Zhou Mei, Li Gaonian, Zhang Qian, et al. Study on application of spontaneous combustion coal gangue aggregate in ready-mixed concrete[J]. Journal of Building Materials, 2015, 18(5): 830-835. doi: 10.3969/j.issn.1007-9629.2015.05.020 [21] Yang Z H, Huang J, Zeng G M, et al. Optimization of flocculation conditions for Kaolin suspension using the composite flocculant of MBFGA1 and PAC by response surface methodology[J]. Bioresource Technology, 2009, 100(18): 4233-4239. doi: 10.1016/j.biortech.2008.12.033 [22] Alenyorege E A, Ma H L, Aheto J H, et al. Response surface methodology centred optimization of mono-frequency ultrasound reduction of bacteria in fresh-cut Chinese cabbage and its effect on quality[J]. LWT, 2020, 122: 108991. doi: 10.1016/j.lwt.2019.108991 [23] 郝成亮, 郭金玉, 初茉, 等. 基于响应面法的长焰煤浮选工艺模型及因子作用分析[J]. 矿业科学学报, 2019, 4(6): 547-557. http://kykxxb.cumtb.edu.cn/article/id/257Hao Chengliang, Guo Jinyu, Chu Mo, et al. Analysis of models and factors of long flame coal flotation process by response surface methodology[J]. Journal of Mining Science and Technology, 2019, 4(6): 547-557. http://kykxxb.cumtb.edu.cn/article/id/257 [24] 袁汉卿, 蒋友宝, 崔玉理, 等. 再生骨料透水混凝土的透水性和抗压强度[J]. 材料导报, 2018, 32(S2): 466-470. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2018S2106.htmYuan Hanqing, Jiang Youbao, Cui Yuli, et al. Permeability and compressive strength of recycled aggregate permeable concrete[J]. Materials Review, 2018, 32(S2): 466-470. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2018S2106.htm [25] 蒋正武, 孙振平, 王培铭. 若干因素对多孔透水混凝土性能的影响[J]. 建筑材料学报, 2005, 8(5): 513-519. doi: 10.3969/j.issn.1007-9629.2005.05.008Jiang Zhengwu, Sun Zhenping, Wang Peiming. Effects of some factors on properties of porous pervious concrete[J]. Journal of Building Materials, 2005, 8(5): 513-519. doi: 10.3969/j.issn.1007-9629.2005.05.008 [26] 李学德, 贾守刚, 杜应吉. 基于正交试验分析影响透水混凝土性能的主要因素[J]. 中国农村水利水电, 2011(11): 66-69. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNSD201111020.htmLi Xuede, Jia Shougang, Du Yingji. An analysis of the main factors of pervious concrete's properties based on orthogonal experiment[J]. China Rural Water and Hydropower, 2011(11): 66-69. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNSD201111020.htm [27] 吴秀峰, 周梅, 崔正龙. 自燃煤矸石粗集料对混凝土强度影响的试验研究[J]. 工业建筑, 2009, 39(3): 81-85. https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ200903027.htmWu Xiufeng, Zhou Mei, Cui Zhenglong. The experiment research on concrete strength influence of self combustion coal gangue coarse aggregate[J]. Industrial Construction, 2009, 39(3): 81-85. https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ200903027.htm [28] 姜骞, 周华新, 谢德擎, 等. 透水混凝土增强剂对透水混凝土性能的影响[J]. 混凝土, 2018(1): 64-67. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201801016.htmJiang Qian, Zhou Huaxin, Xie Deqing, et al. Influence of pervious concrete reinforcing agent on the performance of pervious concrete[J]. Concrete, 2018(1): 64-67. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201801016.htm [29] 付培江, 石云兴, 屈铁军, 等. 透水混凝土强度若干影响因素及收缩性能的试验研究[J]. 混凝土, 2009(8): 18-21. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF200908007.htmFu Peijiang, Shi Yunxing, Qu Tiejun, et al. Experimental study on strength and shrinkage properties of pervious concrete[J]. Concrete, 2009(8): 18-21. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF200908007.htm [30] 张勇, 贾文文, 徐长科, 等. 不同因素对透水混凝土性能影响的研究[J]. 混凝土与水泥制品, 2017(11): 25-28. https://www.cnki.com.cn/Article/CJFDTOTAL-HNTW201711006.htmZhang Yong, Jia Wenwen, Xu Changke, et al. Study on the effect of different factors on the properties of pervious concrete[J]. China Concrete and Cement Products, 2017(11): 25-28. https://www.cnki.com.cn/Article/CJFDTOTAL-HNTW201711006.htm [31] 李政. 不同水灰比对透水混凝土性能影响研究[J]. 湖南交通科技, 2019, 45(1): 56-58, 91. https://www.cnki.com.cn/Article/CJFDTOTAL-FLJT201901014.htmLi Zheng. Study on the effect of different water-cement ratio on the performance of permeable concrete[J]. Hunan Communication Science and Technology, 2019, 45(1): 56-58, 91. https://www.cnki.com.cn/Article/CJFDTOTAL-FLJT201901014.htm [32] 王靖, 刘钦焱, 蔡鹏, 等. 再生骨料透水混凝土的性能及影响因素研究[J]. 新型建筑材料, 2018, 45(9): 42-46. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201809015.htmWang Jing, Liu Qinyan, Cai Peng, et al. Experimental study on properties and influencing factors of recycled aggregate pervious concrete[J]. New Building Materials, 2018, 45(9): 42-46. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201809015.htm -

下载:

下载: