Preparation of admixture by lightly calcinated electronic fluorine-containing sludge mixed with coal gangue and its effect on cement properties

-

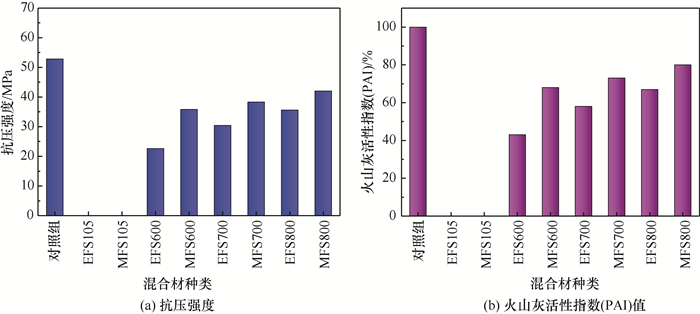

摘要: 直接轻烧电子含氟污泥用作水泥混合材存在火山灰活性不高、标准稠度需水量大等问题,本文利用煤矸石作为电子含氟污泥的硅铝质补充来源,将电子含氟污泥和煤矸石混合后轻烧制备水泥混合材,通过强度活性指数、水泥力学强度、水泥标准稠度需水量、凝结时间、粒度分布等指标以及X射线衍射和扫描电镜等试验,探究了轻烧煤矸石混合电子含氟污泥制备水泥混合材对水泥性能的影响。结果表明:与直接轻烧电子含氟污泥制备的水泥混合材相比,煤矸石混合电子含氟污泥后轻烧制备的水泥混合材,可改善水泥的颗粒级配,降低水泥的标准稠度需水量,提高水泥混合材的活性和所配制普通硅酸盐水泥强度,但会使水泥的初凝时间延长、终凝时间缩短。Abstract: In view of the problems posed by low pozzolanic activity and large water requirement of normal consistency in the direct light calcinating of electronic fluorine-containing sludge as cement admixture, this paper uses coal gangue as a supplementary silicon and aluminum source of electronic fluorine-containing sludge to mix electronic fluorine-containing sludge and coal gangue and then to prepare cement admixture by light calcinating. This paper studied the effect of cement admixture prepared by light calcinating electronic fluorine-containing mixed with sludge coal gangue on cement properties through strength activity index, mechanical properties of cement, water requirement of normal consistency, setting time, particle size, X-ray diffraction and scanning electron microscopy. The results show that compared with direct light calcinating of electronic fluorine-containing sludge to prepare cement admixture, light calcinating of electronic fluorine-containing sludge mixed with coal gangue can improve the particle gradation of cement and reduce the water requirement of normal consistency of cement. It can significantly improve the activity of cement admixture and the strength of ordinary portland cement. Significantly extending the initial setting time and shorten the final setting time of cement.

-

表 1 EFS、CC、CG和GP的化学组成

Table 1. Chemical compositions of EFS, CC, CG and GP

% Oxide SiO2 Al2O3 CaO Fe2O3 MgO SO3 K2O P2O5 F L. O. I Others CC 22.81 5.49 63.79 3.36 1.52 0.30 1.12 0.09 0.02 0.80 0.70 EFS 8.99 6.52 34.76 3.21 2.43 1.82 0.09 9.64 15.63 15.72 1.19 CG 50.29 19.75 3.81 3.98 0.74 2.91 1.94 0.08 — 15.60 0.90 GP 1.48 0.51 50.12 0.30 0.36 43.67 0.08 0.02 — — 3.46 表 2 掺加不同水泥混合材的水泥配方

Table 2. Proportion of cement with different cement admixtures

水泥种类 轻烧温度/℃ wEFS/% wCG/% wCC/% wGP/% 对照组 — 0 0 95 5 S0-1 105 20 0 75 5 S0-2 14 6 75 5 S6-1 600 20 0 75 5 S6-2 14 6 75 5 S7-1 700 20 0 75 5 S7-2 14 6 75 5 S8-1 800 20 0 75 5 S8-2 14 6 75 5 表 3 掺加不同混合材水泥的标准稠度需水量

Table 3. Water requirement of normal consistency of the cement with different admixtures addition

水泥种类 轻烧温度/℃ 标准稠度需水量/% 对照组 — 28.6 S0-1 105 46.2 S0-2 45.4 S6-1 600 33.9 S6-2 32.5 S7-1 700 32.5 S7-2 31.9 S8-1 800 32.3 S8-2 30.5 表 4 掺加不同混合材水泥的凝结时间

Table 4. Setting time of the cement with different admixtures addition

水泥种类 轻烧温度/℃ 凝结时间/min 初凝 终凝 对照组 — 100 190 S0-1 105 7 10 S0-2 8 12 S6-1 600 80 270 S6-2 100 240 S7-1 700 75 238 S7-2 85 215 S8-1 800 55 208 S8-2 83 195 表 5 掺加不同混合材水泥的等效粒径

Table 5. Equivalent particle size of cement added with different admixtures

水泥种类 D10/μm D50/μm D90/μm 离散度 对照组 2.400 13.913 43.355 2.94 S8-1 1.727 9.868 45.417 4.43 S8-2 1.965 11.234 44.562 3.79 -

[1] Zeng G S, Ling B, Li Z J, et al. Fluorine removal and calcium fluoride recovery from rare-earth smelting wastewater using fluidized bed crystallization process[J]. Journal of Hazardous Materials, 2019, 373: 313-320. doi: 10.1016/j.jhazmat.2019.03.050 [2] Drouiche N, Ghaffour N, Lounici H, et al. Electrochemical treatment of chemical mechanical polishing wastewater: removal of fluoride-sludge characteristics-operating cost[J]. Desalination, 2008, 223(1/2/3): 134-142. [3] 雷绍民, 郭振华. 氟污染的危害及含氟废水处理技术研究进展[J]. 金属矿山, 2012, 41(4): 152-155, 159. doi: 10.3969/j.issn.1001-1250.2012.04.039Lei Shaomin, Guo Zhenhua. Hazards of fluoride pollution and technical research progress of treating fluoride-containing wastewater[J]. Metal Mine, 2012, 41(4): 152-155, 159. doi: 10.3969/j.issn.1001-1250.2012.04.039 [4] Tantawy M A. Characterization and pozzolanic properties of calcined alum sludge[J]. Materials Research Bulletin, 2015, 61: 415-421. doi: 10.1016/j.materresbull.2014.10.042 [5] 何廷树, 王敏豪, 达永琪, 等. 含氟污泥的理化性质及其对水泥性能和环境安全性的影响[J]. 硅酸盐学报, 2020, 48(8): 1295-1301. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB202008017.htmHe Tingshu, Wang Minhao, Da Yongqi, et al. Physicochemical performance of fluorine-containing sludge and its effect on cement properties and environmental safety[J]. Journal of the Chinese Ceramic Society, 2020, 48(8): 1295-1301. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB202008017.htm [6] 王俊杰, 赵娇娇, 孟旭超, 等. 光伏光电行业含氟废水及污泥利用处置研究现状及展望[J]. 环境工程技术学报, 2018, 8(3): 333-342. doi: 10.3969/j.issn.1674-991X.2018.03.044Wang Junjie, Zhao Jiaojiao, Meng Xuchao, et al. Research status and prospect of fluorinated wastewater and sludge utilization in photovoltaic industry[J]. Journal of Environmental Engineering Technology, 2018, 8(3): 333-342. doi: 10.3969/j.issn.1674-991X.2018.03.044 [7] Krishnan N. Design for environment in semiconductor manufacturing[J]. Dissertation Abstracts International, 2003, 64-09: 4581. [8] Da Y Q, He T S, Shi C, et al. Potential of preparing cement clinker by adding the fluorine-containing sludge into raw meal[J]. Journal of Hazardous Materials, 2021, 403: 123692. doi: 10.1016/j.jhazmat.2020.123692 [9] Lin W T. Characterization and permeability of cement-based materials containing calcium fluoride sludge[J]. Construction and Building Materials, 2019, 196: 564-573. doi: 10.1016/j.conbuildmat.2018.11.126 [10] He T S, Da Y Q, Shi C, et al. Recovery of thermally treated fluorine-containing sludge as the substitutions of Portland cement[J]. Journal of Cleaner Production, 2020, 260: 121030. doi: 10.1016/j.jclepro.2020.121030 [11] 宋旭艳, 宫晨琛, 李东旭. 煤矸石活化过程中结构特性和力学性能的研究[J]. 硅酸盐学报, 2004, 32(3): 358-363. doi: 10.3321/j.issn:0454-5648.2004.03.028Song Xuyan, Gong Chenchen, Li Dongxu. Study on structural characteristic and mechanical property of coal gangue in activation process[J]. Journal of the Chinese Ceramic Society, 2004, 32(3): 358-363. doi: 10.3321/j.issn:0454-5648.2004.03.028 [12] 张海鸿. 煤矸石的复合活化技术研究[D]. 西安: 长安大学, 2009. [13] 郭伟, 李东旭, 陈建华, 等. 热活化与机械力活化对煤矸石胶凝性的影响[J]. 建筑材料学报, 2011, 14(3): 371-375. doi: 10.3969/j.issn.1007-9629.2011.03.016Guo Wei, Li Dongxu, Chen Jianhua, et al. Effect of heat activated and mechanical force activated method on coal gangue cementing performance[J]. Journal of Building Materials, 2011, 14(3): 371-375. doi: 10.3969/j.issn.1007-9629.2011.03.016 [14] Mojumdar S C, Kozánková J, Chocholoušek J, et al. Fluoroapatite-material for medicine, growth, morphology and thermoanalytical properties[J]. Journal of Thermal Analysis and Calorimetry, 2004, 78(1): 73-82. doi: 10.1023/B:JTAN.0000042155.26913.79 [15] García R, de la Villa R V, Vegas I, et al. The pozzolanic properties of paper sludge waste[J]. Construction and Building Materials, 2008, 22(7): 1484-1490. doi: 10.1016/j.conbuildmat.2007.03.033 [16] Cheng H F, Liu Q F, Yang J, et al. Thermogravimetric analysis of selected coal-bearing strata kaolinite[J]. Thermochimica Acta, 2010, 507/508: 84-90. doi: 10.1016/j.tca.2010.05.004 [17] Cao Z, Cao Y D, Dong H J, et al. Effect of calcination condition on the microstructure and pozzolanic activity of calcined coal gangue[J]. International Journal of Mineral Processing, 2016, 146: 23-28. doi: 10.1016/j.minpro.2015.11.008 [18] 周尚永, 李月霞, 张意, 等. 煤矸石热活化技术及其活性评价探讨[J]. 建筑技术开发, 2012, 39(8): 57-60. https://www.cnki.com.cn/Article/CJFDTOTAL-JZKF201208018.htmZhou Shangyong, Li Yuexia, Zhang Yi, et al. Discussion on thermal activation technology and activity evaluation of coal gangue[J]. Building Technique Development, 2012, 39(8): 57-60. https://www.cnki.com.cn/Article/CJFDTOTAL-JZKF201208018.htm [19] 杨慧芬, 张金龙, 王亚运, 等. 古交东曲矿区煤矸石活性混合材的制备与应用[J]. 煤炭工程, 2015, 47(3): 115-118. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ201503039.htmYang Huifen, Zhang Jinlong, Wang Yayun, et al. Preparation and utilization of active mixed materials from coal gangue of Gujiao dongqu mining area[J]. Coal Engineering, 2015, 47(3): 115-118. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ201503039.htm [20] 刘可高, 朱慧, 蒋元海. 煤矸石作水泥混合材的活化方法研究[J]. 粉煤灰综合利用, 2004, 17(6): 3-6. doi: 10.3969/j.issn.1005-8249.2004.06.001Liu Kegao, Zhu Hui, Jiang Yuanhai. Study on the activation method of CG (coal gangue)used as cement admixture[J]. Fly Ash Comprehensive Utilization, 2004, 17(6): 3-6. doi: 10.3969/j.issn.1005-8249.2004.06.001 [21] Ferreiro S, Frías M, de la Villa R V, et al. The influence of thermal activation of art paper sludge on the technical properties of blended Portland cements[J]. Cement and Concrete Composites, 2013, 37: 136-142. doi: 10.1016/j.cemconcomp.2012.11.005 [22] Naamane S, Rais Z, Taleb M. The effectiveness of the incineration of sewage sludge on the evolution of physicochemical and mechanical properties of Portland cement[J]. Construction and Building Materials, 2016, 112: 783-789. doi: 10.1016/j.conbuildmat.2016.02.121 [23] Tang P, Florea M V A, Spiesz P, et al. Application of thermally activated municipal solid waste incineration (MSWI)bottom ash fines as binder substitute[J]. Cement and Concrete Composites, 2016, 70: 194-205. doi: 10.1016/j.cemconcomp.2016.03.015 [24] 张振. 活化铜尾矿及其碱激发胶凝材料制备研究[D]. 重庆: 重庆大学, 2017. [25] 郭伟, 李东旭, 陈建华, 等. 添加不同温度煅烧煤矸石水泥的早期水化及浆体的显微结构[J]. 硅酸盐学报, 2005, 33(7): 897-901, 906. doi: 10.3321/j.issn:0454-5648.2005.07.020Guo Wei, Li Dongxu, Chen Jianhua, et al. Early hydration and paste microstructure of cement with coal gangue calcined at different temperatures[J]. Journal of the Chinese Ceramic Society, 2005, 33(7): 897-901, 906. doi: 10.3321/j.issn:0454-5648.2005.07.020 [26] 曹永丹, 曹钊, 张金山. 煅烧煤矸石对硅酸盐水泥胶砂力学性能及微观结构的影响[J]. 硅酸盐通报, 2019, 38(2): 356-362. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201902009.htmCao Yongdan, Cao Zhao, Zhang Jinshan. Effect of calcined coal gangue on the mechanical property and microstructure of hydrated Portland cement[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(2): 356-362. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201902009.htm [27] Kang S M, Seo J T, Park S H, et al. Qualitative analysis on crystal growth of synthetic hydroxyapatite influenced by fluoride concentration[J]. Archives of Oral Biology, 2019, 104: 52-59. doi: 10.1016/j.archoralbio.2019.05.022 -

下载:

下载: