Mechanical anisotropy and interlayer bonding strength of 3D printing geopolymer

-

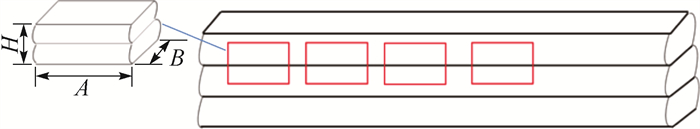

摘要: 3D打印地聚合物是一种兼具资源化利用及智能建造的新型建筑材料,其试件各方向上的力学性能和层间的黏结强度是影响建筑可建造性和耐久性的重要因素。以粉煤灰、石英砂为主要原材料,无水硅酸钠为碱激发剂,矿粉为辅助性胶凝材料,硅酸镁铝为专用外加剂,制备了3D打印粉煤灰基地聚合物砂浆;在最适宜掺量和配比下,3D打印出粉煤灰基地聚合物3D打印试件,研究了其层间黏结强度与抗拉强度,并且通过力学性能及超声波速表征其力学各向异性性能。Abstract: 3D printing geopolymer is a new type of building way and material with both of resource utilization and intelligent building. The mechanical properties in all directions and the bonding strength between layers of components are important factors affecting the constructability and durability of buildings.3D printing geopolymer mortar was prepared with fly ash and quartz sand as main raw materials, anhydrous sodium silicate as alkali activator, slag powder as auxiliary cementitious material, magnesium aluminum silicate as special additive. The 3D printing component of fly ash-based geopolymer was prepared under the condition of the optimum dosage and proportion. The interlayer bonding strength and tensile strength were studied, and the mechanical anisotropy properties were characterized by mechanical properties and ultrasonic pulse velocity.

-

表 1 主要原材料的化学成分

Table 1. Chemical compositions of main raw materials

% 化学组分 Na2O MgO Al2O3 SiO2 SO3 Fe2O3 K2O CaO TiO2 Loss 粉煤灰 0.39 0.85 28.39 53.71 0.87 5.68 2.71 5.10 1.54 0.76 矿粉 0.22 5.59 13.11 32.59 0.64 0.70 0.31 45.64 0.64 0.56 表 2 粉煤灰基3D打印地聚合物配合比设计

Table 2. Mix proportions of fly ash based geopolymer for 3D printing

g 粉煤灰 矿粉 水 碱激发剂 石英砂 硅酸镁铝 450.0 50.0 150.0 50.0 750.0 5.0 -

[1] 张超, 邓智聪, 马蕾, 等. 3D打印混凝土研究进展及其应用[J]. 硅酸盐通报, 2021, 40(6): 1769-1795. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202106002.htmZhang Chao, Deng Zhicong, Ma Lei, et al. Research progress and application of 3D printing concrete[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(6): 1769-1795. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202106002.htm [2] Hager I, Golonka A, Putanowicz R. 3D printing of buildings and building components as the future of sustainable construction?[J]. Procedia Engineering, 2016, 151: 292-299. doi: 10.1016/j.proeng.2016.07.357 [3] 王雨珅, 郝亮, 李正, 等. 3D打印地质聚合物的研究进展和应用探索[J]. 中国建材科技, 2021, 30(3): 36-40. https://www.cnki.com.cn/Article/CJFDTOTAL-JCKJ202103007.htmWang Yushen, Hao Liang, Li Zheng, et al. Research progress and application exploration of 3D printing geopolymer[J]. China Building Materials Science & Technology, 2021, 30(3): 36-40. https://www.cnki.com.cn/Article/CJFDTOTAL-JCKJ202103007.htm [4] 张慧琳, 程磊. 3D打印用地质聚合物配合比的优化试验[J]. 低温建筑技术, 2020, 42(4): 35-37. https://www.cnki.com.cn/Article/CJFDTOTAL-DRAW202004009.htmZhang Huilin, Cheng Lei. Optimization tests of geopolymer mixture ratio for 3D printing[J]. Low Temperature Architecture Technology, 2020, 42(4): 35-37. https://www.cnki.com.cn/Article/CJFDTOTAL-DRAW202004009.htm [5] Tay Y W D, Panda B, Paul S C, et al. 3D printing trends in building and construction industry: a review[J]. Virtual and Physical Prototyping, 2017, 12(3): 261-276. doi: 10.1080/17452759.2017.1326724 [6] Kothman I, Faber N. How 3D printing technology changes the rules of the game[J]. Journal of Manufacturing Technology Management, 2016, 27(7): 932-943. doi: 10.1108/JMTM-01-2016-0010 [7] Bos F, Wolfs R, Ahmed Z, et al. Additive manufacturing of concrete in construction: potentials and challenges of 3D concrete printing[J]. Virtual and Physical Prototyping, 2016, 11(3): 209-225. doi: 10.1080/17452759.2016.1209867 [8] Le T T, Austin S A, Lim S, et al. Mix design and fresh properties for high-performance printing concrete[J]. Materials and Structures, 2012, 45(8): 1221-1232. doi: 10.1617/s11527-012-9828-z [9] 李福平, 邓春林, 万晶. 3D打印建筑技术与商品混凝土行业展望[J]. 混凝土世界, 2013(3): 28-29. https://www.cnki.com.cn/Article/CJFDTOTAL-JZSJ201303007.htmLi Fuping, Deng Chunlin, Wan Jing. Prospect of 3D printing construction technology and commercial concrete industry[J]. China Concrete, 2013(3): 28-29. https://www.cnki.com.cn/Article/CJFDTOTAL-JZSJ201303007.htm [10] Han Y L, Yang Z H, Ding T, et al. Environmental and economic assessment on 3D printed buildings with recycled concrete[J]. Journal of Cleaner Production, 2021, 278: 123884. doi: 10.1016/j.jclepro.2020.123884 [11] Garg A, Vijayaraghavan V, Zhang J, et al. Robust model design for evaluation of power characteristics of the cleaner energy system[J]. Renewable Energy, 2017, 112: 302-313. doi: 10.1016/j.renene.2017.05.041 [12] Kaur M, Singh J, Kaur M. Synthesis of fly ash based geopolymer mortar considering different concentrations and combinations of alkaline activator solution[J]. Ceramics International, 2018, 44(2): 1534-1537. doi: 10.1016/j.ceramint.2017.10.071 [13] Garg A, Li J H, Hou J J, et al. A new computational approach for estimation of wilting point for green infrastructure[J]. Measurement, 2017, 111: 351-358. doi: 10.1016/j.measurement.2017.07.026 [14] Panda B, Paul S C, Hui L J, et al. Additive manufacturing of geopolymer for sustainable built environment[J]. Journal of Cleaner Production, 2017, 167: 281-288. doi: 10.1016/j.jclepro.2017.08.165 [15] Nematollahi B, Xia M, Sanjayan J, et al. Effect of type of fiber on inter-layer bond and flexural strengths of extrusion-based 3D printed geopolymer[J]. Materials Science Forum, 2018, 939: 155-162. doi: 10.4028/www.scientific.net/MSF.939.155 [16] Guo X L, Yang J Y, Xiong G Y. Influence of supplementary cementitious materials on rheological properties of 3D printed fly ash based geopolymer[J]. Cement and Concrete Composites, 2020, 114: 103820. doi: 10.1016/j.cemconcomp.2020.103820 [17] 郭晓潞, 杨君奕, 熊归砚. 硅酸镁铝及静置时间对3D打印地聚合物砂浆流变性能的影响[J]. 建筑材料学报, 2022, 25(1): 89-96. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX202201013.htmGuo Xiaolu, Yang Junyi, Xiong Guiyan. Effect of magnesium aluminum silicate and rest time on rheological property of 3D printing geopolymer mortar[J]. Journal of Building Materials, 2022, 25(1): 89-96. https://www.cnki.com.cn/Article/CJFDTOTAL-JZCX202201013.htm [18] Lencis U, Udris A, Korjakins A. Frost influence on the ultrasonic pulse velocity in concrete at early phases of hydration process[J]. Case Studies in Construction Materials, 2021, 15: 00614. [19] Solís-Carcaño R, Moreno E I. Evaluation of concrete made with crushed limestone aggregate based on ultrasonic pulse velocity[J]. Construction and Building Materials, 2008, 22(6): 1225-1231. doi: 10.1016/j.conbuildmat.2007.01.014 [20] Guo X L, Xiong G Y, Zhang H M. In-situ evaluation of self-healing performance of Engineered Geopolymer Composites (EGC)by ultrasonic method[J]. Materials Letters, 2020, 280: 128546. doi: 10.1016/j.matlet.2020.128546 -

下载:

下载: