Study on activity characteristics of modified coal gasification coarse slag and its hydration hardening properties of blended cement paste

-

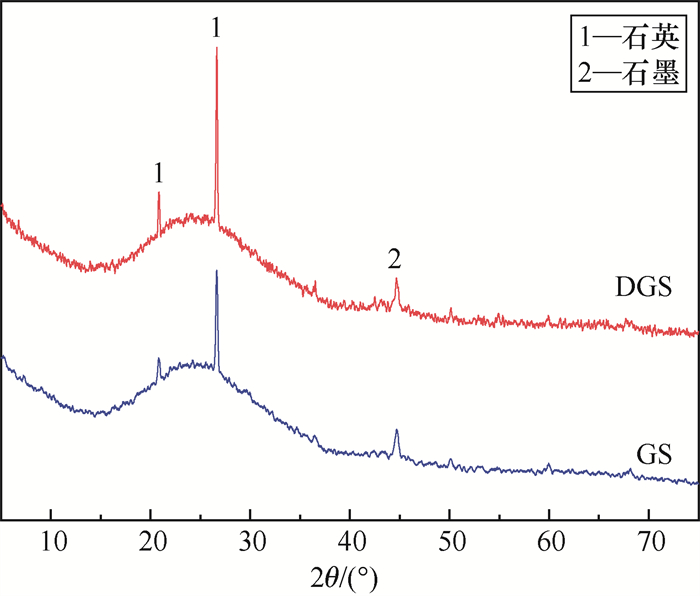

摘要: 煤气化技术的规模化应用产生了大量难处理的煤气化灰渣。作为一种富含硅铝酸盐矿物的煤气化灰渣,具备火山灰活性和较低的碳含量特征,可作为辅助性胶凝材料使用。为探讨不同改性效果下煤气化粗渣的活性特征及其对水泥水化硬化性能的影响机制,本文从宏观和微观上对掺有改性气化粗渣的复合水泥浆体的水化放热、抗压强度、水化产物组成与结构进行分析比较。结果表明:添加二乙醇单异丙醇胺(DEIPA)改性,可明显地提升气化粗渣的粉磨效率和潜在水化活性,有效减少水化诱导期的延长,降低气化粗渣掺加对水泥水化的缓凝效果;添加DEIPA的顺序对复合水泥的水化硬化特性影响不大。经化学和物理协同改性后的煤气化粗渣可以用于硅酸盐水泥的混合材和混凝土的掺合料,在适当掺量(10 %)下可提升复合水泥的力学性能。Abstract: The large-scale application of coal gasification technology produces a large amount of coal gasification slag that is difficult to handle. As a kind of coal gasification ash rich in aluminosilicate minerals, coal gasification coarse slag has the characteristics of pozzolanic activity and low carbon content, and can be used as supplementary cementitious material. In order to explore the activity characteristics of coal gasification coarse slag under different modification effects and its influence mechanism on the hydration and hardening performance of cement, this paper analyzed the hydration exotherm, compressive strength, composition and structure of hydration products of the blended cement paste mixed with modified gasification slag, which were compared from macroscopic and microscopic perspectives. The results show that the addition and modification of diethanol monoisopropanolamine (DEIPA) can significantly improve the grinding efficiency and potential hydration activity of gasification coarse slag, effectively reduce the extension of hydration induction period and reduce the retarding effect of gasification coarse slag on cement hydration. The addition order of DEIPA has little effect on the hydration hardening properties of blended cement. The coal gasification coarse slag modified by chemical and physical coordination can be used as the admixture of Portland cement and concrete, and the mechanical properties of blended cement can be improved under the appropriate dosage (10 %).

-

表 1 水泥与气化粗渣化学成分

Table 1. Chemical composition of cement and GS

% 材料 SiO2 Al2O3 Fe2O3 CaO MgO SO3 Loss 水泥 20.78 5.01 3.50 63.93 2.01 2.21 1.80 气化粗渣 52.52 16.70 11.58 8.67 2.00 3.12 3.6 表 2 两种改性气化粗渣和水泥的筛余量及比表面积

Table 2. Sieve residue and specific surface area of different modified gasification slag and cement

参数 水泥 GS DGS 筛余量(0.045 μm)/% 3.6 3.4 3.1 比表面积/(m2·kg-1) 377 412 445 -

[1] 朱菊芬, 李健, 闫龙, 等. 煤气化渣资源化利用研究进展及应用展望[J]. 洁净煤技术, 2021, 27(6): 11-21. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS202106002.htmZhu Jufen, Li Jian, Yan Long, et al. Research progress and application prospect of coal gasification slag resource utilization[J]. Clean Coal Technology, 2021, 27(6): 11-21. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS202106002.htm [2] 汪寿建. 现代煤气化技术发展趋势及应用综述[J]. 化工进展, 2016, 35(3): 653-664. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201603001.htmWang Shoujian. Development and application of modern coal gasification technology[J]. Chemical Industry and Engineering Progress, 2016, 35(3): 653-664. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201603001.htm [3] Andersson A, Deng J J, Du K, et al. Regionally-varying combustion sources of the January 2013 severe haze events over Eastern China[J]. Environmental Science & Technology, 2015, 49(4): 2038-2043. [4] You C F, Xu X C. Coal combustion and its pollution control in China[J]. Energy, 2010, 35(11): 4467-4472. doi: 10.1016/j.energy.2009.04.019 [5] 宁永安, 段一航, 高宁博, 等. 煤气化渣组分回收与利用技术研究进展[J]. 洁净煤技术, 2020, 26(S1): 14-19. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS2020S1003.htmNing Yongan, Duan Yihang, Gao Ningbo, et al. Progress of component recycling and utilization technology of coal gasification slag[J]. Clean Coal Technology, 2020, 26(S1): 14-19. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS2020S1003.htm [6] 赵社库. 我国煤化工产业现状及发展建议[J]. 化工管理, 2019(21): 14-15. doi: 10.3969/j.issn.1008-4800.2019.21.010Zhao Sheku. Present situation and development suggestions of coal chemical industry in China[J]. Chemical Enterprise Management, 2019(21): 14-15. doi: 10.3969/j.issn.1008-4800.2019.21.010 [7] Li S H, Whitty K J. Physical phenomena of char-slag transition in pulverized coal gasification[J]. Fuel Processing Technology, 2012, 95: 127-136. doi: 10.1016/j.fuproc.2011.12.006 [8] Wu S Y, Huang S, Ji L Y, et al. Structure characteristics and gasification activity of residual carbon from entrained-flow coal gasification slag[J]. Fuel, 2014, 122: 67-75. doi: 10.1016/j.fuel.2014.01.011 [9] 张明, 房奎圳, 王栋民, 等. 掺改性煤气化渣水泥新拌浆体与减水剂相容性研究[J]. 矿业科学学报, 2021, 6(6): 737-745. doi: 10.19606/j.cnki.jmst.2021.06.013Zhang Ming, Fang Kuizhen, Wang Dongmin, et al. Study on compatibility of fresh cement paste mixed with modified coal gasification slag and superplasticizer[J]. Journal of Mining Science and Technology, 2021, 6(6): 737-745. doi: 10.19606/j.cnki.jmst.2021.06.013 [10] 郭照恒, 杨文, 祝小靓, 等. 不同比表面积煤气化渣掺合料活性及力学性能研究[J]. 硅酸盐通报, 2020, 39(11): 3567-3573, 3588. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202011025.htmGuo Zhaoheng, Yang Wen, Zhu Xiaoliang, et al. Activity and mechanical properties of coal gasification slag admixture with different specific surface area[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(11): 3567-3573, 3588. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202011025.htm [11] 焦玉荣, 张栩瑞, 张亚, 等. 煤气化渣负载Ni@SiO2/TiO2材料的制备及其催化性能研究[J]. 功能材料, 2022, 53(2): 2156-2161. doi: 10.3969/j.issn.1001-9731.2022.02.023Jiao Yurong, Zhang Xurui, Zhang Ya, et al. Preparation and characterization of Ni@SiO2/TiO2 composite supported on coal gasification slag[J]. Journal of Functional Materials, 2022, 53(2): 2156-2161. doi: 10.3969/j.issn.1001-9731.2022.02.023 [12] 牛国峰, 刘芳, 贾晓林. 煤气化渣烧结制品的烧成制度研究[J]. 耐火材料, 2022, 56(1): 61-64. https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL202201014.htmNiu Guofeng, Liu Fang, Jia Xiaolin. Research on firing system of coal gasification slag sintered products[J]. Refractories, 2022, 56(1): 61-64. https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL202201014.htm [13] 牛国峰. 煤气化渣制备烧结墙体材料工艺及烧结机理研究[D]. 包头: 内蒙古科技大学, 2021. [14] 武立波, 宋牧原, 谢鑫, 等. 中国煤气化渣建筑材料资源化利用现状综述[J]. 科学技术与工程, 2021, 21(16): 6565-6574. doi: 10.3969/j.issn.1671-1815.2021.16.004Wu Libo, Song Muyuan, Xie Xin, et al. A review on resource utilization of coal gasification slag as building materials in China[J]. Science Technology and Engineering, 2021, 21(16): 6565-6574. doi: 10.3969/j.issn.1671-1815.2021.16.004 [15] 高春新, 井云环, 陈慧君, 等. 煤气化渣脱除燃煤烟气中汞的性能研究[J]. 燃料化学学报, 2021, 49(4): 455-464. https://www.cnki.com.cn/Article/CJFDTOTAL-RLHX202104008.htmGao Chunxin, Jing Yunhuan, Chen Huijun, et al. Performance of Hg0 removal from coal-fired flue gas over coal gasification slag[J]. Journal of Fuel Chemistry and Technology, 2021, 49(4): 455-464. https://www.cnki.com.cn/Article/CJFDTOTAL-RLHX202104008.htm [16] 席雅允, 沈玉, 刘娟红, 等. 化学激发对煤气化渣-水泥体系抗压强度影响机理研究[J]. 材料导报, 2021, 35(S2): 262-267, 274. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2021S2051.htmXi Yayun, Shen Yu, Liu Juanhong, et al. Influence mechanism of chemical excitation on compressive strength of slag cement system in coal gasification[J]. Materials Reports, 2021, 35(S2): 262-267, 274. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2021S2051.htm [17] 古悦, 王栋民, 房奎圳, 等. 煤气化渣溶出特性及对水泥基材料的影响[J]. 硅酸盐通报, 2021, 40(5): 1579-1585. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202105020.htmGu Yue, Wang Dongmin, Fang Kuizhen, et al. Dissolution characteristics of coal gasification slag and its effect on cement-based materials[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(5): 1579-1585. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202105020.htm [18] 康健. 煤气化渣掺量对其复合胶凝材料的性能影响分析[J]. 西部交通科技, 2020(8): 61-64. https://www.cnki.com.cn/Article/CJFDTOTAL-XBJT202008019.htmKang Jian. Influence of coal gasification slag content on the properties of its composite cementitious material[J]. Western China Communications Science & Technology, 2020(8): 61-64. https://www.cnki.com.cn/Article/CJFDTOTAL-XBJT202008019.htm [19] 吕学涛. 激发剂对煤气化渣微粉胶凝体系性能的影响研究[D]. 包头: 内蒙古科技大学, 2019. [20] 刘晨. 硅铝质内养护材料在蒸养混凝土中的应用研究[D]. 武汉: 武汉理工大学, 2019. [21] 秦玉珠, 汪宁, 魏丽丹, 等. 对改性粉煤灰中硅铝铁溶出率的研究[J]. 长春师范大学学报, 2014, 33(4): 90-93. doi: 10.3969/j.issn.1008-178X.2014.04.031Qin Yuzhu, Wang Ning, Wei Lidan, et al. A study of the dissolution rates of silicon, aluminum and iron from modified fly ash[J]. Journal of Changchun Normal University, 2014, 33(4): 90-93. doi: 10.3969/j.issn.1008-178X.2014.04.031 [22] 张志平. 重金属离子在水泥基材料中的电化学溶出行为研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. [23] 王奕仁, 王栋民, 翟梦怡, 等. 聚合铝对锂渣-水泥复合胶凝材料水化硬化特性的影响[J]. 矿业科学学报, 2019, 4(1): 86-94. http://kykxxb.cumtb.edu.cn/article/id/201Wang Yiren, Wang Dongmin, Zhai Mengyi, et al. Effect of polymeric aluminum on hydration hardening characteristics of lithium slag-cement composite cementitious materials[J]. Journal of Mining Science and Technology, 2019, 4(1): 86-94. http://kykxxb.cumtb.edu.cn/article/id/201 [24] 宋普涛, 王晶, 关青锋, 等. 混凝土用珊瑚砂氯离子溶出规律研究[J]. 材料导报, 2020, 34(S2): 1250-1254, 1260. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2020S2051.htmSong Putao, Wang Jing, Guan Qingfeng, et al. Study on chloride ion dissolution of coral sand for concrete[J]. Materials Reports, 2020, 34(S2): 1250-1254, 1260. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2020S2051.htm [25] 刘泽, 李丽, 邵宁宁, 等. 钢渣-粉煤灰水热合成方沸石及其性能表征[J]. 矿业科学学报, 2018, 3(5): 508-514. http://kykxxb.cumtb.edu.cn/article/id/178Liu Ze, Li Li, Shao Ningning, et al. Hydrothermal synthesis of analcime from steel slag-fly ash and its performance characterization[J]. Journal of Mining Science and Technology, 2018, 3(5): 508-514. http://kykxxb.cumtb.edu.cn/article/id/178 [26] 王炳文, 高利晶, 赵文华, 等. 玲珑金矿胶结剂固结尾砂的微观实验[J]. 矿业科学学报, 2019, 4(6): 524-530. http://kykxxb.cumtb.edu.cn/article/id/254Wang Bingwen, Gao Lijing, Zhao Wenhua, et al. Microscopic experiment of consolidating tailings by Linglong cementitious material[J]. Journal of Mining Science and Technology, 2019, 4(6): 524-530. http://kykxxb.cumtb.edu.cn/article/id/254 [27] 余鑫, 于诚, 姜骞, 等. 采用原位XRD研究早强剂对水泥早期水化的影响[J]. 材料导报, 2020, 34(2): 2058-2062. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202002011.htmYu Xin, Yu Cheng, Jiang Qian, et al. In-situ X-ray diffraction analysis on the role of hardening accelerator in early hydration of cement[J]. Materials Reports, 2020, 34(2): 2058-2062. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202002011.htm -

下载:

下载: