Study of the nonlinear mechanical behavior of rock materials using the FFT numerical method based on the actual mesostructure

-

摘要: 岩石的非均质性(矿物夹杂、微裂隙、微孔洞等细观结构)对其非线性力学行为和破坏过程有着显著影响。本文采用无需对复杂细观结构划分网格的快速傅立叶变换(FFT)数值方法,直接获取图像中的像素点作为材料点,准确得到非均质材料的细观结构特征和力学性质的特点,与数字图像处理(DIP)技术有机结合,建立了基于真实细观结构的FFT数值计算方法,模拟了非均质岩石在外荷载作用下的弹塑性变形过程,探究了岩石内部细观结构对非线性力学行为的影响规律与宏观力学性质的内在联系。研究结果表明:基于真实细观结构的FFT模型,能很好地预测不同埋深和不同围压条件下黏土岩的峰前非线性行为和峰值强度,细观结构的形状、大小和分布直接决定了黏土岩内部应力场的分布。研究结论为研究岩石细观结构特征及其非线性力学行为提供了一个重要手段。Abstract: Rock heterogeneity (such as mineral inclusions, micro-cracks, micro-voids and other microstructures) significantly affects its nonlinear mechanical behavior and failure process. This paper utilizes the Fast Fourier transform-based(FFT) numerical method which does not require meshing of complex microstructure but directly obtains the microstructure of heterogeneous materials through the pixels of the image. In addition, the method can be naturally combined with digital image processing (DIP). An actual-microstructure-based FFT method is thereby developed to simulate the elastoplastic behavior of the heterogeneous rocks under external load. The influence of microstructure on the nonlinear behavior is discussed as well as the internal relationship between the microstructure and the macroscopic mechanical properties. The results show that the real-microstructure-based FFT method can well predict the nonlinear behavior before and after the peak strength of the rocks under different depths and confining pressures. The shape, size and distribution of microstructure directly determine the distribution of stress field in clay rock. The actual-microstructure-based FFT method proposed in this paper can reasonably consider the rock heterogeneity, and provides an important tool for studying the influence of the rock microstructure characteristics on the nonlinear mechanical behavior.

-

Key words:

- Fast Fourier Transforms (FFT) method /

- digital image process /

- rocks /

- micromechanics /

- heterogeneity

-

图 6 材料点生成过程[18]

Figure 6. Material point generation process

图 8 像素对边界的影响[31]

Figure 8. The effect of the pixel on the boundary

图 9 细观结构和局部本构模型的关系[12]

Figure 9. Relationship between microstructure and local constitutive model

表 1 COx黏土岩细观介质的弹性参数[32]

Table 1. Elastic parameters of meso-medium of COx clay rock

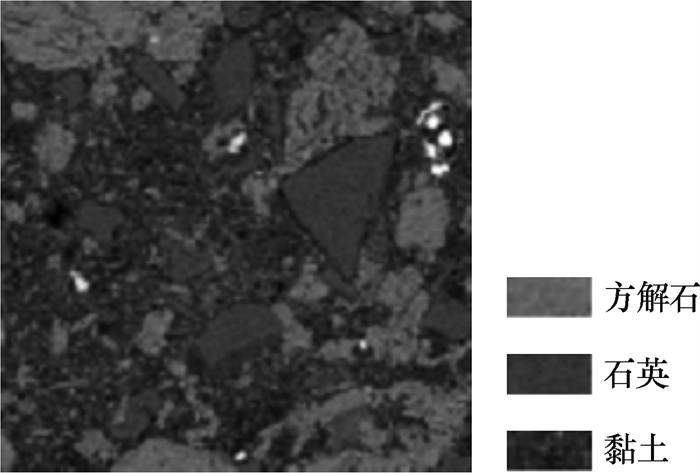

材料 弹性模量/GPa 泊松比 石英 101 0.06 方解石 95 0.27 黏土 3 0.3 表 2 不同深度各种矿物的含量[32]

Table 2. The content of various minerals at different depths

深度/m 石英含量/% 方解石含量/% 黏土含量/% 实测 模拟 实测 模拟 实测 模拟 451.5 32 29 19 18 49 53 451.4 22 21 31 27 47 52 469.0 23 20 33 31 44 49 469.1 22 21 23 24 55 55 482.2 14 13 26 26 60 61 -

[1] 陈沙, 岳中琦, 谭国焕. 基于真实细观结构的岩土工程材料三维数值分析方法[J]. 岩石力学与工程学报, 2006, 25(10): 1951-1959. doi: 10.3321/j.issn:1000-6915.2006.10.002Chen Sha, Yue Zhongqi, Tan Guohuan. Actual mesostructure based three-dimensional numerical modeling method for heterogeneous geomaterials[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(10): 1951-1959. doi: 10.3321/j.issn:1000-6915.2006.10.002 [2] 程虹铭, 杨小彬, 刘隽嘉, 等. 基于损伤演化的砂岩能量参数围压效应研究[J]. 矿业科学学报, 2020, 5(3): 249-256. http://kykxxb.cumtb.edu.cn/article/id/286Cheng Hongming, Yang Xiaobin, Liu Junjia, et al. Confining pressure effect on energy parameters of sandstones based on damage evolution[J]. Journal of Mining Science and Technology, 2020, 5(3): 249-256. http://kykxxb.cumtb.edu.cn/article/id/286 [3] 滕腾, 杜玉冰, 陈朋飞, 等. 砂岩变形率与水理效应的力学特性研究[J]. 矿业科学学报, 2020, 5(3): 342-352. http://kykxxb.cumtb.edu.cn/article/id/298Teng Teng, Du Yubing, Chen Pengfei, et al. Effects of deformation rate and hydrated condition on the mechanical property of sandstone[J]. Journal of Mining Science and Technology, 2020, 5(3): 342-352. http://kykxxb.cumtb.edu.cn/article/id/298 [4] Mahabadi O K, Randall N X, Zong Z, et al. A novel approach for micro-scale characterization and modeling of geomaterials incorporating actual material heterogeneity[J]. Geophysical Research Letters, 2012, 39(1): 1303. [5] Mahabadi O K, Tatone B S A, Grasselli G. Influence of microscale heterogeneity and microstructure on the tensile behavior of crystalline rocks[J]. Journal of Geophysical Research: Solid Earth, 2014, 119(7): 5324-5341. doi: 10.1002/2014JB011064 [6] Jing L. A review of techniques, advances and outstanding issues in numerical modelling for rock mechanics and rock engineering[J]. International Journal of Rock Mechanics and Mining Sciences, 2003, 40(3): 283-353. doi: 10.1016/S1365-1609(03)00013-3 [7] 李德建, 祁浩, 李春晓, 等. 含层理面煤试样的巴西圆盘劈裂实验及数值模拟研究[J]. 矿业科学学报, 2020, 5(2): 150-159. http://kykxxb.cumtb.edu.cn/article/id/275Li Dejian, Qi Hao, Li Chunxiao, et al. Brazilian disc splitting tests and numerical simulations on coal samples containing bedding planes[J]. Journal of Mining Science and Technology, 2020, 5(2): 150-159. http://kykxxb.cumtb.edu.cn/article/id/275 [8] 于庆磊, 杨天鸿, 郑超, 等. 岩石细观结构对其变形强度影响的数值分析[J]. 岩土力学, 2011, 32(11): 3468-3472. doi: 10.3969/j.issn.1000-7598.2011.11.044Yu Qinglei, Yang Tianhong, Zheng Chao, et al. Numerical analysis of influence of rock mesostructure on its deformation and strength[J]. Rock and Soil Mechanics, 2011, 32(11): 3468-3472. doi: 10.3969/j.issn.1000-7598.2011.11.044 [9] 朱泽奇, 肖培伟, 盛谦, 等. 基于数字图像处理的非均质岩石材料破坏过程模拟[J]. 岩土力学, 2011, 32(12): 3780-3786. doi: 10.3969/j.issn.1000-7598.2011.12.040Zhu Zeqi, Xiao Peiwei, Sheng Qian, et al. Numerical simulation of fracture propagation of heterogeneous rock material based on digital image processing[J]. Rock and Soil Mechanics, 2011, 32(12): 3780-3786. doi: 10.3969/j.issn.1000-7598.2011.12.040 [10] Hu X J, Xie N, Zhu Q Z, et al. Modeling damage evolution in heterogeneous granite using digital image-based Grain-Based Model[J]. Rock Mechanics and Rock Engineering, 2020: 4925-4945. [11] 韩振华, 张路青, 周剑, 等. 矿物粒径对花岗岩单轴压缩特性影响的试验与模拟研究[J]. 工程地质学报, 2019, 27(3): 497-504. https://www.cnki.com.cn/Article/CJFDTOTAL-GCDZ201903005.htmHan Zhenhua, Zhang Luqing, Zhou Jian, et al. Uniaxial compression test and numerical studies of grain size effect on mechanical properties of granite[J]. Journal of Engineering Geology, 2019, 27(3): 497-504. https://www.cnki.com.cn/Article/CJFDTOTAL-GCDZ201903005.htm [12] Li M Y, Zuo J P, Hu D W, et al. Experimental and numerical investigation of microstructure effect on the mechanical behavior and failure process of brittle rocks[J]. Computers and Geotechnics, 2020, 125: 103639. doi: 10.1016/j.compgeo.2020.103639 [13] Escoda J, Willot F, Jeulin D, et al. Estimation of local stresses and elastic properties of a mortar sample by FFT computation of fields on a 3D image[J]. Cement and Concrete Research, 2011, 41(5): 542-556. doi: 10.1016/j.cemconres.2011.02.003 [14] Li M Y, Cao Y J, Shen W Q, et al. A damage model of mechanical behavior of porous materials: application to sandstone[J]. International Journal of Damage Mechanics, 2018, 27(9): 1325-1351. doi: 10.1177/1056789516685379 [15] Manouchehrian A, Cai M. Influence of material heterogeneity on failure intensity in unstable rock failure[J]. Computers and Geotechnics, 2016, 71: 237-246. doi: 10.1016/j.compgeo.2015.10.004 [16] Li M Y, Shen W Q, Shao J F. A numerical study of effective mechanical behaviors of rock like materials based on Fast Fourier Transform[J]. Mechanics of Materials, 2016, 92: 275-288. doi: 10.1016/j.mechmat.2015.10.004 [17] Yue Z Q, Chen S, Tham L G. Finite element modeling of geomaterials using digital image processing[J]. Computers and Geotechnics, 2003, 30(5): 375-397. doi: 10.1016/S0266-352X(03)00015-6 [18] Wu Z J, Ji X K, Liu Q S, et al. Study of microstructure effect on the nonlinear mechanical behavior and failure process of rock using an image-based-FDEM model[J]. Computers and Geotechnics, 2020, 121: 103480. doi: 10.1016/j.compgeo.2020.103480 [19] Tan X, Konietzky H, Chen W. Numerical simulation of heterogeneous rock using discrete element model based on digital image processing[J]. Rock Mechanics and Rock Engineering, 2016, 49(12): 4957-4964. doi: 10.1007/s00603-016-1030-0 [20] Yang Y T, Xu D D, Zheng H. Explicit discontinuous deformation analysis method with lumped mass matrix for highly discrete block system[J]. International Journal of Geomechanics, 2018, 18(9): 1-10. [21] Ghossein E, Levesque M. A comprehensive validation of analytical homogenization models: The case of ellipsoidal particles reinforced composites[J]. Mechanics of Materials, 2014, 75: 135-150. doi: 10.1016/j.mechmat.2014.03.014 [22] Liu H Y, Kou S Q, Lindqvist P A, et al. Numerical modelling of the heterogeneous rock fracture process using various test techniques[J]. Rock Mechanics and Rock Engineering, 2007, 40(2): 107-144. doi: 10.1007/s00603-006-0091-x [23] 岳中琦, 陈沙, 郑宏, 等. 岩土工程材料的数字图像有限元分析[J]. 岩石力学与工程学报, 2004, 23(6): 889-897. doi: 10.3321/j.issn:1000-6915.2004.06.002Yue Zhongqi, Chen Sha, Zheng Hong, et al. Digital image proceeding based on finite element method for geomaterials[J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(6): 889-897. doi: 10.3321/j.issn:1000-6915.2004.06.002 [24] Ghossein E, Levesque M. A fully automated numerical tool for a comprehensive validation of homogenization models and its application to spherical particles reinforced composites[J]. International Journal of Solids and Structures, 2012, 49(11-12): 1387-1398. doi: 10.1016/j.ijsolstr.2012.02.021 [25] Robinet J C. Minéralogie, porosité et diffusion des solutés dans l'argilite du Callovo-Oxfordien de Bure (Meuse, Haute-Marne, France) de l'échelle centimétrique à micrométrique[D]. France: Universit de poitiers, 2008. [26] 于庆磊. 基于数字图像的岩石类材料破裂过程分析方法研究[D]. 沈阳: 东北大学, 2008. [27] Moulinec H, Suquet P. A fast numerical method for computing the linear and nonlinear mechanical properties of composites[J]. Cmes-Computer Modeling in Engineering and Sciences, 1994, 318(11): 1417-1423. [28] Moulinec H, Suquet P. A numerical method for computing the overall response of nonlinear composites with complex microstructure[J]. Computer Methods in Applied Mechanics and Engineering, 1998, 157(1/2): 69-94. [29] Mahabadi O K, Lisjak A, Munjiza A, et al. Y-geo: New combined finite-discrete element numerical code for geomechanical applications[J]. International Journal of Geomechanics, 2012, 12(6): 676-688. doi: 10.1061/(ASCE)GM.1943-5622.0000216 [30] 凌天龙, 刘殿书, 梁书锋, 等. 花岗岩损伤型黏弹性动态本构模型研究[J]. 矿业科学学报, 2019, 4(5): 403-409. http://kykxxb.cumtb.edu.cn/article/id/239Ling Tianlong, Liu Dianshu, Liang Shufeng, et al. Research on damage viscoelastic dynamic constitutive model of granite[J]. Journal of Mining Science and Technology, 2019, 4(5): 403-409. http://kykxxb.cumtb.edu.cn/article/id/239 [31] Li Mingyao. Contribution à la modélisation multi-échelle du comportement mécanique des matériaux rocheux[D]. France: Université de Lille 1 Sciences et Technologies, 2015. [32] Guery A A C, Cormery F, Shao J F, et al. A micromechanical model of elastoplastic and damage behavior of a cohesive geomaterial[J]. International Journal of Solids and Structures, 2008, 45(5): 1406-1429. doi: 10.1016/j.ijsolstr.2007.09.025 -

下载:

下载: