The influence of functional groups in frothers on foaming performance and foam stability

-

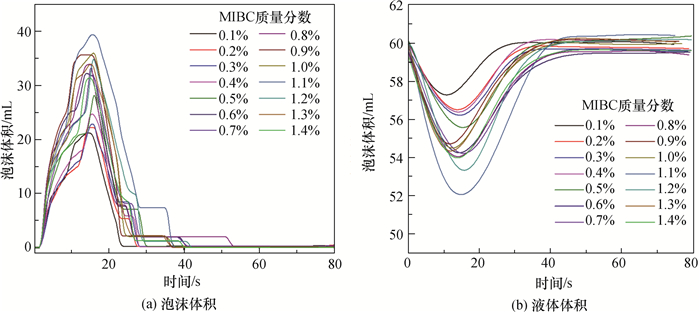

摘要: 浮选是分离微细物料的重要方法,起泡剂类型和泡沫稳定性显著影响浮选效果。本文选取醇类(MIBC)、酯类(DEP)和醚醇类(DGBE)三种起泡剂,通过实验研究官能团对起泡性能和泡沫稳定性的影响。实验用Foamscan测定起泡剂溶液的起泡性能和泡沫稳定性,用Tracker流变仪测定表面张力和气液界面黏弹模量。研究结果表明:起泡速率随表面张力的减小呈线性增大,当气液界面吸附起泡剂达到饱和时起泡速率最大,其中MIBC的起泡速率最高,DGBE最小; 起泡剂浓度为临界质量分数时,起泡能力最大,MIBC、DEP和DGBE的临界质量分数分别为1.1 %、0.4 % 和0.8 %; 气泡的大小随溶液表面张力减小而减小,气泡平均尺寸由大至小顺序为:DGBE>DEP>MIBC; 在泡沫稳定性方面,醚醇类起泡剂最强,醇类起泡剂最差,同时MIBC、DEP和DGBE质量分数分别为0.4 %、0.5 % 和0.8 % 时,起泡剂生成的泡沫最稳定。Abstract: Flotation is an important method for the separation of fine materials.The type of frothers and the stability of the foam significantly affect flotation performance.In this paper, three foaming agents of alcohols (MIBC), esters (DEP) and ether alcohols (DGBE) are selected to investigate the effect of functional groups in frothers on foaming performance and foam stability.Foamscan was used in the experiment to determine the foaming performance and foam stability of the frothers, and the Tracker rheometer was used to determine surface tension and the viscoelastic modulus of the air-liquid interface.Results show that the foaming rate increases linearly with the decrease of surface tension.It reaches its peak/the maximum when the gas-liquid interface adsorbs the foaming agent to saturation, and when the adsorption of the foaming agent on the gas-liquid interface reaches saturation.The foaming rate of MIBC reaches its peak/the maximum and that of DGBE its trough/the minumum.When the concentration of the frother reaches the critical mass fraction, the foaming ability reaches its peak/the maximum, and the critical mass fractions of MIBC, DEP and DGBE are 1.1 %, 0.4 % and 0.8 %.The size of the bubbles decreases with the decrease of the surface tension of the solution, and the order of the average bubble size from large to small is: DGBE>DEP>MIBC.The ether alcohol frothers have the strongest foam stability, while the alcohol frothers have the worst foam stability.The foam is the most stable.when the mass fractions of MIBC, DEP and DGBE are 0.4 %, 0.5 % and 0.8 %.

-

Key words:

- functional group /

- foaming ability /

- foam stability /

- surface tension /

- viscoelastic modulus

-

表 1 实验药剂

Table 1. Experimental reagent

名称 结构简式 官能团 来源 甲基异丁基甲醇(MIBC) (CH3)2CHCH2(OH) CH3 —OH 上海麦克林生化 邻苯二甲酸二乙酯(DEP) CH3CH2OOCC6H4COOCH2CH3 —COO— 阿拉丁 二乙二醇丁醚(DGBE) HO(CH2)2O(CH2)2O(CH2)3CH3 —OH+—O— 北京华威锐科化工 表 2 官能团对泡沫的生成速率、气泡破裂速率、起泡速率的影响

Table 2. Effects of functional groups on foam formation rate, bubble rupture rate and foaming rate

质量分数/% 泡沫生成速率/(mL·s-1) 气泡破裂速率/(mL·s-1) 起泡速率/(mL·s-1) —OH —COO— —OH+—O— —OH —COO— —OH+—O— —OH —COO— —OH+—O— 0.1 1.101 0.542 1.547 2.653 3.257 1.750 3.755 3.799 3.298 0.2 1.248 0.611 1.717 2.745 3.526 1.778 3.992 4.137 3.496 0.3 1.388 0.757 2.198 2.797 3.418 1.410 4.184 4.174 3.608 0.4 1.576 1.035 2.262 2.727 3.221 1.542 4.302 4.256 3.804 0.5 1.761 0.859 2.405 2.616 3.407 1.593 4.377 4.266 3.998 0.6 2.233 0.691 2.476 2.207 3.577 1.643 4.440 4.268 4.119 0.7 2.262 0.587 2.601 2.293 3.679 1.574 4.556 4.266 4.175 0.8 2.310 0.468 2.724 2.361 3.793 1.465 4.671 4.261 4.189 0.9 2.407 0.401 2.674 2.377 3.867 1.531 4.784 4.268 4.206 1.0 2.449 0.350 2.567 2.461 3.914 1.651 4.910 4.264 4.218 1.1 2.669 — 2.462 2.524 — 1.750 5.192 — 4.212 1.2 2.417 — 2.441 2.776 — 1.775 5.192 — 4.216 1.3 2.335 — — 2.857 — — 5.192 — — 1.4 1.874 — — 3.319 — — 5.192 — — -

[1] Zhu H Z, Song S X, López Valdivieso A, et al. Effects of rectifying bundles on desliming ponds[J]. International Journal of Coal Preparation and Utilization, 2021, 41(1): 30-39. doi: 10.1080/19392699.2018.1433170 [2] 李国胜, 韩加展, 邓丽君, 等. 气泡在煤炭表面的碰撞和黏附过程[J]. 煤炭学报, 2016, 41(11): 2841-2846. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201611025.htmLi Guosheng, Han Jiazhan, Deng Lijun, et al. Collision and adhesion process of air bubbles on coal surface[J]. Journal of China Coal Society, 2016, 41(11): 2841-2846. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201611025.htm [3] 朱宏政, 王海艳, 王海楠, 等. 机械搅拌式浮选装置中气泡粒径分布规律[J]. 煤炭学报, 2018, 43(4): 1140-1145. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201804043.htmZhu Hongzheng, Wang Haiyan, Wang Hainan, et al. Bubble size distribution in a mechanical flotation device[J]. Journal of China Coal Society, 2018, 43(4): 1140-1145. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201804043.htm [4] Grau R A, Laskowski J S, Heiskanen K. Effect of frothers on bubble size[J]. International Journal of Mineral Processing, 2005, 76(4): 225-233. doi: 10.1016/j.minpro.2005.01.004 [5] 解维伟. 煤乳化浮选药剂的制备与应用机理研究[D]. 北京: 中国矿业大学(北京), 2009. [6] 邱宁. 复配起泡剂及性能研究[D]. 淮南: 安徽理工大学, 2016. [7] 黄秋霞, 郭东红, 刘亚文, 等. 起泡剂的起泡性能及使用浓度优选研究[J]. 精细与专用化学品, 2014, 22(6): 33-35. doi: 10.3969/j.issn.1008-1100.2014.06.009Huang Qiuxia, Guo Donghong, Liu Yawen, et al. Study on foam performance and concentration optimization of foaming agents[J]. Fine and Specialty Chemicals, 2014, 22(6): 33-35. doi: 10.3969/j.issn.1008-1100.2014.06.009 [8] 侯晓博, 徐初阳. 起泡剂组分对浮选效果的影响研究[J]. 选煤技术, 2010(6): 8-11, 2. doi: 10.3969/j.issn.1001-3571.2010.06.003Hou Xiaobo, Xu Chuyang. Study on the effect of different component of foaming agents on result of coal flotation[J]. Coal Preparation Technology, 2010(6): 8-11, 2. doi: 10.3969/j.issn.1001-3571.2010.06.003 [9] 黎冰, 杜杰, 高玉峰, 等. 发泡剂性能评价指标[J]. 东南大学学报: 自然科学版, 2020, 50(4): 651-657. https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX202004008.htmLi Bing, Du Jie, Gao Yufeng, et al. Performance evaluation indexes of foaming agent[J]. Journal of Southeast University: Natural Science Edition, 2020, 50(4): 651-657. https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX202004008.htm [10] 黄建平, 卢毅屏, 赵刚, 等. 浮选起泡剂及其研究新进展[J]. 金属矿山, 2012(12): 66-74. doi: 10.3969/j.issn.1001-1250.2012.12.018Huang Jianping, Lu Yiping, Zhao Gang, et al. Review on flotation frothers and its research progress[J]. Metal Mine, 2012(12): 66-74. doi: 10.3969/j.issn.1001-1250.2012.12.018 [11] 徐振洪, 朱建华, 张荣曾. 浮选起泡剂泡沫稳定性的评价方法研究[J]. 化工学报, 1999, 50(3): 399-403. doi: 10.3321/j.issn:0438-1157.1999.03.017Xu Zhenhong, Zhu Jianhua, Zhang Rongzeng. Study on evaluation method of flotation frother's froth stability[J]. Journal of Chemical Industry and Engineering: China, 1999, 50(3): 399-403. doi: 10.3321/j.issn:0438-1157.1999.03.017 [12] Y·S·楚, 周高云, 雨田. 浮选起泡剂对气泡大小和泡沫稳定性的影响[J]. 国外金属矿选矿, 2002, 39(9): 17-21. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200209002.htmY·S· Chu, Zhou Gaoyun, Yu Tian. Effect of flotation froth on bubble size and foam stability[J]. Metallic Ore Dressing Abroad, 2002, 50(9): 17-21. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200209002.htm [13] Tan Y H, Finch J A. Frother structure-property relationship: Aliphatic alcohols and bubble rise velocity[J]. Minerals Engineering, 2016, 96/97: 33-38. doi: 10.1016/j.mineng.2016.05.014 [14] Tan Y H, Finch J A. Frother structure-property relationship: Effect of alkyl chain length in alcohols and polyglycol ethers on bubble rise velocity[J]. Minerals Engineering, 2016, 95: 14-20. doi: 10.1016/j.mineng.2016.05.012 [15] Tan Y H, Finch J A. Frother structure-property relationship: Effect of hydroxyl position in alcohols on bubble rise velocity[J]. Minerals Engineering, 2016, 92: 1-8. doi: 10.1016/j.mineng.2016.02.003 [16] 曾培, 欧乐明, 冯其明, 等. 起泡剂MIBC和BK-201的浮选泡沫特性[J]. 中国有色金属学报, 2015, 25(8): 2276-2283. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201508031.htmZeng Pei, Ou Leming, Feng Qiming, et al. Froth characteristic of MIBC and BK-201 frothers[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2276-2283. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201508031.htm [17] 周永锋, 罗溪梅, 林起镪, 等. 四种阳离子捕收剂的起泡性能与表面张力研究[J]. 昆明理工大学学报: 自然科学版, 2020, 45(3): 39-44. https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG202003007.htmZhou Yongfeng, Luo Ximei, Lin Qiqiang, et al. A research on foaming properties and surface tension of four cationic collectors[J]. Journal of Kunming University of Science and Technology: Natural Science, 2020, 45(3): 39-44. https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG202003007.htm [18] 胡晓莹, 李英, 张辉, 等. 泡沫液膜的分子动力学模拟及泡沫析液机制的研究[J]. 化学学报, 2010, 68(2): 131-135. https://www.cnki.com.cn/Article/CJFDTOTAL-HXXB201002005.htmHu Xiaoying, Li Ying, Zhang Hui, et al. Molecular dynamics simulation of foam films and analysis of foam drainage mechanism[J]. Acta Chimica Sinica, 2010, 68(2): 131-135. https://www.cnki.com.cn/Article/CJFDTOTAL-HXXB201002005.htm [19] 黄波, 赵丽霞, 李霞, 等. 起泡剂性能及其对煤泥浮选的影响研究[J]. 洁净煤技术, 2015, 21(1): 11-14, 5. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201501005.htmHuang Bo, Zhao Lixia, Lixia, et al. Properties of frother and its influence on coal slime flotation[J]. Clean Coal Technology, 2015, 21(1): 11-14, 5. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201501005.htm [20] 黄波, 刘国伟, 封萍, 等. 阳离子对十二烷基硫酸钠起泡性能及界面性质的影响[J]. 矿业科学学报, 2018, 3(1): 76-83. http://kykxxb.cumtb.edu.cn/article/id/124Huang Bo, Liu Guowei, Feng Ping, et al. Influence of cations on foaming characteristics and interfacial properties of sodium dodecyl sulfate[J]. Journal of Mining Science and Technology, 2018, 3(1): 76-83. http://kykxxb.cumtb.edu.cn/article/id/124 -

下载:

下载: