Corrosion behavior of the new wear resistant steels Ti60 and ANM450 applied for middle plates of scraper conveyor

-

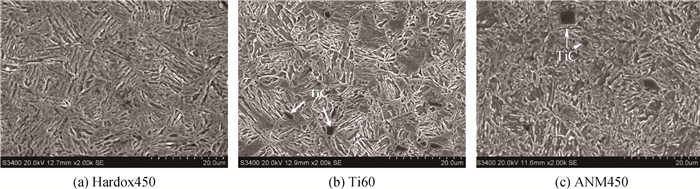

摘要: 以刮板输送机中板用新型耐磨钢Ti60与ANM450为研究对象,分析了微观组织和相结构,采用全浸失重法、电化学测试法及XRD分析研究了2种耐磨钢在去离子水、腐蚀离子溶液、成垢离子溶液、模拟矿井水溶液4种水质中的腐蚀行为。结果表明,腐蚀程度排序均为腐蚀离子溶液>模拟矿井水>成垢离子溶液>去离子水; 耐腐蚀性能Ti60>Hardox450>ANM450;腐蚀产物主要成分为Fe2O3、α -FeO(OH)和Fe (OH)3,说明腐蚀反应主要是铁在溶液中的溶解。Abstract: This paper looks into the microstructure and phase structure of the new wear-resistant steels Ti60 and ANM450 applied for middle plates of scraper conveyer.Their corrosion behaviors in deionized water, corrosion ion solution, scaling ion solution and simulated mine water were studied by weight loss method, electrochemical tests and XRD analysis.The results showed that the corrosion order was corrosion ion solution>simulated mine water>scaling ion solution>deionized water. The order of corrosion resistance was Ti60 > Hardox450 > ANM450.The corrosion products were Fe2O3、α -FeO(OH) and Fe (OH)3, which indicated that iron was dissolved during the corrosion process.

-

Key words:

- new wear resistant steel /

- uniform corrosion /

- electrochemical corrosion

-

表 1 试验钢的化学成分

Table 1. Chemical compositions of three tested steels

% 材料 C Ti Si Mn Ni Mo Cr S P Hardox450 0.23 0 0.50 1.60 0.25 0.25 1.20 0.010 0.025 0 Ti60 0.31 0.61 0.15 0.56 0.61 0.31 0.82 0.006 0.004 0 ANM450 0.30 0.49 1.09 3.02 1.50 0.27 0.14 0.001 0.009 5 表 2 4种腐蚀溶液的化学成分

Table 2. The chemical compositions of four kinds of corrosive solution

成分 NaCl/(mg·L-1) Na2SO4/(mg·L-1) Mg(OH)2/(mg·L-1) CaCO3/(mg·L-1) pH 去离子水 — — — — 7.0 腐蚀离子溶液 137.18 2 993.56 — — 7.0 成垢离子溶液 — — 38.45 422.18 7.8 模拟矿井水 137.18 2 993.56 38.45 422.18 7.8 表 3 试验钢在腐蚀溶液中的腐蚀参数

Table 3. Corrosion parameters of the tested steels in corrosive solutions

腐蚀溶液 耐磨钢 Ecorr/V Rcorr/mmPY 去离子水 Hardox450 -0.299 3 0.054 7 Ti60 -0.274 0 0.042 2 ANM450 -0.376 6 0.062 2 腐蚀离子溶液 Hardox450 -0.440 1 2.684 5 Ti60 -0.417 4 0.709 2 ANM450 -0.497 9 2.889 3 成垢离子溶液 Hardox450 -0.405 7 0.270 8 Ti60 -0.305 4 0.036 4 ANM450 -0.435 3 0.249 8 模拟矿井水 Hardox450 -0.431 7 1.144 3 Ti60 -0.423 9 1.092 5 ANM450 -0.472 2 1.400 3 -

[1] 煤矿安全规程编委会. 煤矿安全规程[M]. 北京: 煤炭工业出版社, 2016. [2] 史志远. 重载刮板输送机中部槽磨损行为研究[D]. 徐州: 中国矿业大学, 2017. [3] 李福固. 矿井运输与提升[M]. 3版. 徐州: 中国矿业大学出版社, 2014: 56-62. [4] 陈维健, 齐秀丽, 肖林京. 矿山运输与提升设备[M]. 徐州: 中国矿业大学出版社, 2007. [5] 张东升, 毛君, 刘占胜. 刮板输送机启动及制动动力学特性仿真与实验研究[J]. 煤炭学报, 2016, 41(2): 513-521. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201602034.htmZhang Dongsheng, Mao Jun, Liu Zhansheng. Dynamics simulation and experiment on the starting and braking of scraper conveyor[J]. Journal of China Coal Society, 2016, 41(2): 513-521. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201602034.htm [6] Shi Z Y, Zhu Z C. Case study: Wear analysis of the middle plate of a heavy-load scraper conveyor chute under a range of operating conditions[J]. Wear, 2017, 380/381: 36-41. doi: 10.1016/j.wear.2017.03.005 [7] 曹庆一, 任文颖, 陈思瑶, 等. 煤矿矿井水处理技术与利用现状[J]. 能源与环保, 2020, 42(3): 100-104. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZMT202003023.htmCao Qingyi, Ren Wenying, Chen Siyao, et al. Coal mine water treatment technology and utilization status[J]. China Energy and Environmental Protection, 2020, 42(3): 100-104. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZMT202003023.htm [8] Waterhouse Carly, Tuff James, Usher Brent. Managed aquifer recharge and mine water management[J]. AusIMM Bulletin, 2017, (10): 76-79. [9] Banks D, Younger P L, Arnesen R T, et al. Mine-water chemistry: the good, the bad and the ugly[J]. Environmental Geology, 1997, 32(3): 157-174. doi: 10.1007/s002540050204 [10] Dong Shuning, Zhang Wenzhong, Zhou Wanfang, et al. Discussion on some topical issues of water prevention and control in coal mines[J]. Mine Water and the Environment, 2021, 40(2): 547-552. doi: 10.1007/s10230-021-00773-3 [11] Bi Y S, Wu J W, Zhai X R, et al. Discriminant analysis of mine water inrush sources with multi-aquifer based on multivariate statistical analysis[J]. Environmental Earth Sciences, 2021, 80(4): 1-17. [12] Gao L, Barrett D, Chen Y, et al. A systems model combining process-based simulation and multi-objective optimisation for strategic management of mine water[J]. Environmental Modelling & Software, 2014, 60: 250-264. [13] 谭娜. 中锰奥氏体钢矿井水工况的摩擦及腐蚀行为研究[D]. 徐州: 中国矿业大学, 2017. [14] 李沐山. 国外钢结硬质合金新进展[J]. 硬质合金, 1994, 11(2): 105-114. https://www.cnki.com.cn/Article/CJFDTOTAL-YZHJ199402010.htmLi Mushan. New development in foreing steel-bonded hard alloys[J]. Cemented Carbide, 1994, 11(2): 105-114. https://www.cnki.com.cn/Article/CJFDTOTAL-YZHJ199402010.htm [15] 李静. 工程机械用高强度NM450耐磨钢的研究[D]. 天津: 河北工业大学, 2012. [16] 田江漫. 河南永煤矿区选煤厂设备防腐蚀研究[D]. 徐州: 中国矿业大学, 2014. [17] 王振龙, 白飞飞. 选煤厂钢结构锈蚀原因分析[J]. 洁净煤技术, 2018, 24(S2): 33-38. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS2018S2008.htmWang Zhenlong, Bai Feifei. Analysis of the cause of steel structure corrosion in coal preparation plant[J]. Clean Coal Technology, 2018, 24(S2): 33-38. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS2018S2008.htm [18] Zuo X B, Sun W, Li H, et al. Modeling of diffusion-reaction behavior of sulfate ion in concrete under sulfate environments[J]. Computers & Concrete, 2012, 10(1): 79-93. [19] Kodama T. The effect of sulfate ion on the passivity of iron in neutral buffer solution[J]. Corrosion Engineering, 1974, 23(1): 5-10. doi: 10.3323/jcorr1974.23.1_5 [20] Haruna T, Domoto K, Shibata T. Effect of sulfate ion on corrosion of carbon steel in carbonate/bicarbonate solutions[J]. Zairyo-to-Kankyo, 2002, 51(8): 350-355. doi: 10.3323/jcorr1991.51.350 [21] Soosaiprakasam I R, Veawab A. Corrosion and polarization behavior of carbon steel in MEA-based CO2 capture process[J]. International Journal of Greenhouse Gas Control, 2008, 2(4): 553-562. doi: 10.1016/j.ijggc.2008.02.009 -

下载:

下载: