Characteristic of the water-conducting fracture zone development in thick overburden working face with extra-large mining height in western mining area

-

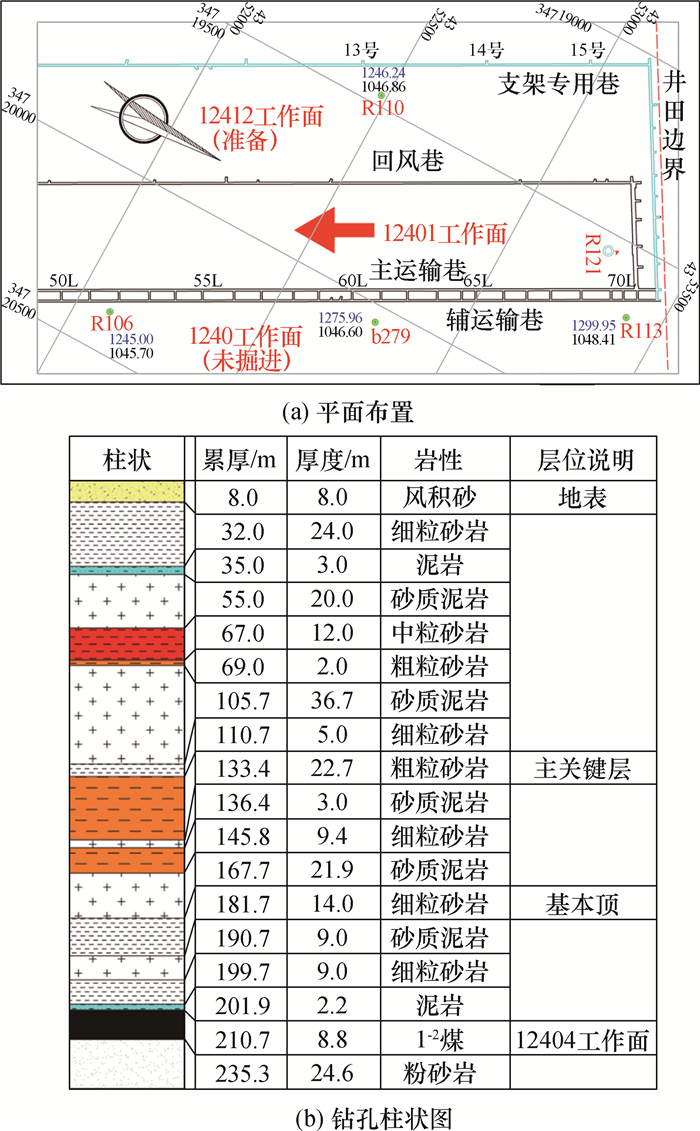

摘要: 为了获得西部矿区部分厚基岩、中等埋深赋存条件下特大采高工作面裂隙发育特征,以上湾矿12401工作面为例,采用经验公式、数值模拟与现场实测相结合的方法进行了对比研究。结果表明:现阶段针对我国东西部矿区典型地质条件获得的经验公式很难适用于本文特大采高、厚基岩、中等埋深地质条件下的工作面。基于西部矿区地质条件的经验公式预测结果明显偏大,而基于东部矿区地质条件的经验公式预测结果则明显偏小。基于损伤本构模型的数值模拟结果与实测结果误差小于5 %,工作面推进过程中导水裂隙带的发育特征为:由于覆岩软硬岩层的存在,导水裂隙带向上呈台阶形发育;裂隙带形态随着采动程度的变化从“拱形”(三维“壳形”)转变为“马鞍形”(三维“盆状形”)的发育过程。Abstract: In order to obtain the fracture development characteristics of the working face with extra-large mining height under the condition of thick overburden and medium mining depth in mining areas in China's western regions, this paper adopted a comparative study by combining empirical equations, numerical simulation and field measurement in the panel 12401 of the Shangwan coal mine.The results show that the empirical equations drawn from data from the typical geological conditions of mining areas in eastern and western China are difficult to apply to this panel with extra-large mining height, thick overburden and medium buried depth.The prediction values of the empirical equations based on data from the geological condition in the western mining regions are generally higher, which are significantly smaller in the eastern mining regions.The value predicted by the numerical simulation based on the damage constitutive model is closer to the measured value than those derived from using empirical equations, with a relative error of less than 5 %.The paper obtained the characteristics of the water-conducting fracture zone development: due to the existence of soft and hard rock in the overburden, the water-conducting fracture zone develops upward as a step, and the shape changes from "arch"(three-dimensional "shell") to "saddle"(three-dimensional "basin shape") with the variation of mining degree.

-

表 1 典型经验公式统计

Table 1. Typical empirical equations statistic

序号 经验公式 研究背景 预测结果/m 文献 1 $H_{\mathrm{d}}=\frac{100 \sum M}{1.6 \sum M+3.6} \pm 5.6 $ 东部矿井中硬覆岩 44.17~55.37 [9] 2 $ H_{\mathrm{d}}=\frac{100 M}{0.095 M+7.28} \pm 8.62$ 神东矿区中硬覆岩 99.81~117.05 [15] 3 $ H_{\mathrm{d}}=0.9 H_{\mathrm{j}}+\frac{10 \sum M}{5.2 M+1.9} \pm 20.0 $ 神东矿区 156.44~196.44 [32] 4 $ H_{\mathrm{d}}=\frac{100 M}{0.71 M+4.82}$ 东部矿井中硬覆岩 79.51 [14] 5 $ H_{\mathrm{d}}=\frac{100 M}{0.23 M+6.1} \pm 10.42$ 厚煤层中硬覆岩 97.9~118.74 [10] 6 Hd=13.96+5.164M+15.496b+0.022H 改进模型 75.60 [33] 7 Hd=22.080+3.741M+14.648b+0.018H 东部矿井 69.77 [7] 8 $ H_{\mathrm{d}}=3.41 M+27.12 b+1.85 \ln l+0.11 \mathrm{e}^{5.346-\frac{426.243}{H}}+0.64 v+6.11$ 东部矿井 76.5 [5-6] 9 Hd=-10.27+61.30ln M+11.82Mb-0.23Mv 神东矿区 182.89 [12] 10 $H_{\mathrm{d}}=25.12 M-3.22 M^{2}+0.14 M^{3}+17.93 b^{0.44}+0.05 L-0.0003 L^{2}+0.079 \mathrm{e}^{4.397-\frac{70}{H}}-\frac{4.37}{\alpha}-14.91 $ 东部矿井 59.01 [13] 11 Hd=36.67+[5.4+0.18ln(L-89.99)+5.22b-1.22ln v+1.02ln(H+30.18)]M 神东矿区 152.11 [11] 注:Hd为导水裂隙带高度,m; M为采高,m; L为工作面宽度,m; l为工作面斜长,m; b为硬岩比例系数; v为推进速度,m/d; H为开深度,m; Hj为基岩厚度,m; α为煤层倾角,(°)。 表 2 模型中岩层的物理力学参数

Table 2. Physico-mechanical parameters of strata in the model

岩性 体积模量/GPa 剪切模量/GPa 内摩擦角/(°) 抗拉强度/MPa 内聚力/MPa 密度/(kg·m-3) 风积沙 0.08 0.02 36.5 0 0.08 1 580 粗粒砂岩 6.30 5.50 30.0 1.78 4.0 2 372 中粒砂岩 8.10 6.37 28.1 1.73 4.6 2 484 细粒砂岩 8.40 6.70 22.4 3.57 4.9 2 615 砂质泥岩 3.18 2.40 18.0 3.77 3.8 2 330 粉砂岩 3 2.47 24.7 2.56 6.2 2 295 泥岩 2.13 0.93 36.6 4.18 3.1 2 311 1-2煤 1.51 5.70 23.6 1.69 2.5 1 280 表 3 采空区单元双屈服模型力学参数

Table 3. Mechanical parameters of the double yield gob elements

应变 0.00 0.02 0.05 0.07 0.10 0.12 0.15 0.17 0.20 应力/MPa 0.00 0.10 0.30 0.60 1.25 2.25 5.00 10.0 20.0 表 4 模拟数据与实测数据分析模型汇总

Table 4. Numerical simulation data and measured data analysis model

校正测定系数R2 自由度 平方和 均方差 F值 F显著性统计量 F临界值 0.94 1 0.03 0.03 0.01 0.001 027 4.96 表 5 不同方法结果对比

Table 5. The comparison of different method results

方法 导水裂隙带高度/m 相对误差/% 裂采比 钻孔实测 120.47~134.46 — 14.19~15.84 公式1 44.17~55.37 -63.33~-58.82 6.29~5.02 公式2 99.81~117.05 -17.09~-12.95 11.34~13.3 公式3 156.44~196.44 29.86~46.10 17.78~22.32 公式4 79.51 -40.87 9.04 公式5 97.9~118.74 -18.73~-11.69 11.13~13.49 公式6 75.60 -43.78 8.59 公式7 69.77 -48.11 7.93 公式8 76.5 -43.11 8.69 公式9 182.89 36.02 20.78 公式10 59.01 -56.11 6.71 公式11 152.11 13.13 17.29 数值模拟 114.84~133.32 -4.67~-0.85 13.05~15.15 -

[1] 胡振琪, 陈超. 风沙区井工煤炭开采对土地生态的影响及修复[J]. 矿业科学学报, 2016, 1(2): 120-130. http://kykxxb.cumtb.edu.cn/article/id/18Hu Zhenqi, Chen Chao. Impact of underground coal mining on land ecology and its restoration in windy and sandy region[J]. Journal of Mining Science and Technology, 2016, 1(2): 120-130. http://kykxxb.cumtb.edu.cn/article/id/18 [2] 王强民, 董书宁, 王皓, 等. 西部风沙区采煤塌陷地裂缝影响下的土壤水分运移规律及调控方法[J]. 煤炭学报, 2021, 46(5): 1532-1540. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202105017.htmWang Qiangmin, Dong Shuning, Wang Hao, et al. Influence of mining subsidence on soil water movement law and its regulation in blown-sand area of Western China[J]. Journal of China Coal Society, 2021, 46(5): 1532-1540. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202105017.htm [3] 郭小铭, 董书宁, 刘英锋, 等. 深埋煤层开采顶板泥砂溃涌灾害形成机理[J]. 采矿与安全工程学报, 2019, 36(5): 889-897. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201905005.htmGuo Xiaoming, Dong Shuning, Liu Yingfeng, et al. Formation mechanism of mud and sand inrush disaster during the mining of deep-buried coal seam[J]. Journal of Mining & Safety Engineering, 2019, 36(5): 889-897. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201905005.htm [4] 郭文兵, 白二虎, 杨达明. 煤矿厚煤层高强度开采技术特征及指标研究[J]. 煤炭学报, 2018, 43(8): 2117-2125. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201808004.htmGuo Wenbing, Bai Erhu, Yang Daming. Study on the technical characteristics and index of thick coal seam high-intensity mining in coalmine[J]. Journal of China Coal Society, 2018, 43(8): 2117-2125. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201808004.htm [5] 胡小娟, 李文平, 曹丁涛, 等. 综采导水裂隙带多因素影响指标研究与高度预计[J]. 煤炭学报, 2012, 37(4): 613-620. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201204016.htmHu Xiaojuan, Li Wenping, Cao Dingtao, et al. Index of multiple factors and expected height of fully mechanized water flowing fractured zone[J]. Journal of China Coal Society, 2012, 37(4): 613-620. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201204016.htm [6] 曹丁涛, 李文平. 煤矿导水裂隙带高度计算方法研究[J]. 中国地质灾害与防治学报, 2014, 25(1): 63-69. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGDH201401017.htmCao Dingtao, Li Wenping. Estimation method for height of fratured zone with water flow in coal mining area[J]. The Chinese Journal of Geological Hazard and Control, 2014, 25(1): 63-69. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGDH201401017.htm [7] 题正义, 秦洪岩, 曹艺钟. 基于敏感度分析的导水裂隙带高度DM-L优化模型[J]. 华中师范大学学报: 自然科学版, 2014, 48(5): 673-676. https://www.cnki.com.cn/Article/CJFDTOTAL-HZSZ201405011.htmTi Zhengyi, Qin Hongyan, Cao Yizhong. DM-L optimization model of height of water flowing fractured zone based on sensitivity analysis[J]. Journal of HuaZhong Normal University: Natural Sciences, 2014, 48(5): 673-676. https://www.cnki.com.cn/Article/CJFDTOTAL-HZSZ201405011.htm [8] 施龙青, 辛恒奇, 翟培合, 等. 大采深条件下导水裂隙带高度计算研究[J]. 中国矿业大学学报, 2012, 41(1): 37-41. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201201008.htmShi Longqing, Xin Henqi, Zhai Peihe, et al. Calculating the height of water flowing fracture zone in deep mining[J]. Journal of China University of Mining & Technology, 2012, 41(1): 37-41. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201201008.htm [9] 胡炳南, 张华兴, 申宝宏. 建筑物、水体、铁路及主要井巷煤柱留设与压煤开采指南[M]. 北京: 煤炭工业出版社, 2017. [10] 刘世奇, 许延春, 郭文砚, 等. 近距离多煤层重复采动"两带"高度预计方法改进[J]. 煤炭科学技术, 2018, 46(5): 74-80. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201805012.htmLiu Shiqi, Xu Yanchun, Guo Wenyan, et al. Improvement of prediction method for heights of caving zone and fractured zone induced by repeated mining of contiguous coal seams[J]. Coal Science and Technology, 2018, 46(5): 74-80. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201805012.htm [11] He X, Zhao Y X, Zhang C, et al. A model to estimate the height of the water-conducting fracture zone for longwall panels in Western China[J]. Mine Water and the Environment, 2020, 39(4): 823-838. doi: 10.1007/s10230-020-00726-2 [12] Liu Yu, Liu Qimeng, Li Wenping, et al. Height of water-conducting fractured zone in coal mining in the soil-rock composite structure overburdens[J]. Environmental Earth Sciences, 2019, 78(7): 1-13. [13] Liu Y, Yuan S C, Yang B B, et al. Predicting the height of the water-conducting fractured zone using multiple regression analysis and GIS[J]. Environmental Earth Sciences, 2019, 78(14): 1-15. [14] 白利民, 尹尚先, 李文. 综采一次采全高顶板导水裂缝带发育高度的计算公式及适用性分析[J]. 煤田地质与勘探, 2013, 41(5): 36-39. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201305010.htmBai Limin, Yin Shangxian, Li Wen. Calculation formula of water conducting zone height in roof for fully mechanized mining & its adaptability analysis[J]. Coal Geology & Exploration, 2013, 41(5): 36-39. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201305010.htm [15] 王云广, 郭文兵, 白二虎, 等. 高强度开采覆岩运移特征与机理研究[J]. 煤炭学报, 2018, 43(S1): 28-35. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2018S1004.htmWang Yunguang, Guo Wenbing, Bai Erhu, et al. Characteristics and mechanism of overlying strata movement due to high-intensity mining[J]. Journal of China Coal Society, 2018, 43(S1): 28-35. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2018S1004.htm [16] 黄万朋, 高延法, 王波, 等. 覆岩组合结构下导水裂隙带演化规律与发育高度分析[J]. 采矿与安全工程学报, 2017, 34(2): 330-335. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201702019.htmHuang Wanpeng, Gao Yanfa, Wang Bo, et al. Evolution rule and development height of permeable fractured zone under combined-strata structure[J]. Journal of Mining & Safety Engineering, 2017, 34(2): 330-335. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201702019.htm [17] 许家林, 朱卫兵, 王晓振. 基于关键层位置的导水裂隙带高度预计方法[J]. 煤炭学报, 2012, 37(5): 762-769. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201205011.htmXu Jialin, Zhu Weibing, Wang Xiaozhen. New method to predict the height of fractured water-conducting zone by location of key strata[J]. Journal of China Coal Society, 2012, 37(5): 762-769. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201205011.htm [18] 王连国, 王占盛, 黄继辉, 等. 薄基岩厚风积沙浅埋煤层导水裂隙带高度预计[J]. 采矿与安全工程学报, 2012, 29(5): 607-612. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201205003.htmWang Lianguo, Wang Zhansheng, Huang Jihui, et al. Prediction on the height of water-flowing fractured zone for shallow seam covered with thin bedrock and thick windblown sands[J]. Journal of Mining & Safety Engineering, 2012, 29(5): 607-612. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201205003.htm [19] 王志强, 李鹏飞, 王磊, 等. 再论采场"三带"的划分方法及工程应用[J]. 煤炭学报, 2013, 38(S2): 287-293. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2013S2006.htmWang Zhiqiang, Li Pengfei, Wang Lei, et al. Method of division and engineering use of "three band"in the stope again[J]. Journal of China Coal Society, 2013, 38(S2): 287-293. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2013S2006.htm [20] 王晓振, 许家林, 韩红凯, 等. 顶板导水裂隙高度随采厚的台阶式发育特征[J]. 煤炭学报, 2019, 44(12): 3740-3749. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201912015.htmWang Xiaozhen, Xu Jialin, Han Hongkai, et al. Stepped development characteristic of water flowing fracture height with variation of mining thickness[J]. Journal of China Coal Society, 2019, 44(12): 3740-3749. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201912015.htm [21] 吴锋锋, 杨敬轩, 于斌, 等. 厚及特厚煤层工作面顶板垮落高度的确定[J]. 中国矿业大学学报, 2014, 43(5): 765-772. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201405002.htmWu Fengfeng, Yang Jingxuan, Yu Bin, et al. Determination of the roof caving heights of thick and extra thick coal seams[J]. Journal of China University of Mining & Technology, 2014, 43(5): 765-772. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201405002.htm [22] 何祥, 张村, 赵毅鑫, 等. 基于覆岩损伤本构模型的高强度开采参数确定及减损效果评价[J]. 采矿与安全工程学报, 2021, 38(3): 439-448. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL202103002.htmHe Xiang, Zhang Cun, Zhao Yixin, et al. Parameters determination of high-intensity mining and reduction effect evaluation based on damage constitutive model of overburden rock[J]. Journal of Mining & Safety Engineering, 2021, 38(3): 439-448. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL202103002.htm [23] 郝宪杰, 孙卓文, 赵毅鑫, 等. 神东保德浅埋煤层覆岩裂隙带高度数值指标判别阈值及采高效应[J]. 矿业科学学报, 2021, 6(4): 472-479. doi: 10.19606/j.cnki.jmst.2021.04.012Hao Xianjie, Sun Zhuowen, Zhao Yixin, et al. Threshold value of numerical index and mining height effect of overburden fracture zone height in Shendong Baode shallow coal seam[J]. Journal of Mining Science and Technology, 2021, 6(4): 472-479. doi: 10.19606/j.cnki.jmst.2021.04.012 [24] 李全生, 徐祝贺, 张勇, 等. 基于Hoek-Brown准则的薄基岩厚松散层覆岩变形破坏特征研究[J]. 矿业科学学报, 2019, 4(5): 417-424. http://kykxxb.cumtb.edu.cn/article/id/241Li Quansheng, Xu Zhuhe, Zhang Yong, et al. Study on deformation and failure characteristics of overlying strata with thick loose layers and thin bedrock based on Hoek-Brown criterion[J]. Journal of Mining Science and Technology, 2019, 4(5): 417-424. http://kykxxb.cumtb.edu.cn/article/id/241 [25] 朱广安, 刘博文, 窦林名, 等. 基于采空区压实效应的工作面开采全过程模拟[J]. 中国矿业大学学报, 2019, 48(4): 775-783. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201904011.htmZhu Guangan, Liu Bowen, Dou Linming, et al. Numerical simulation for whole process of longwall mining on the basis of goaf compaction effect[J]. Journal of China University of Mining & Technology, 2019, 48(4): 775-783. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201904011.htm [26] 杨俊哲, 胡博文, 王振荣. 8.8 m大采高工作面覆岩三带分布特征及分层沉降研究[J]. 煤炭科学技术, 2020, 48(6): 42-48. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202006004.htmYang Junzhe, Hu Bowen, Wang Zhenrong. Study on distribution characteristics of collapse zone, fissure zone and curved subsidence zone and layered settlement of overburden on 8.8 m super-large mining height coal mining face[J]. Coal Science and Technology, 2020, 48(6): 42-48. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202006004.htm [27] 陈超, 高升. 综放开采覆岩导水裂隙带高度综合探测技术[J]. 煤炭工程, 2019, 51(S1): 56-59. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ2019S1014.htmChen Chao, Gao Sheng. Comprehensive detection of overburden water-conducting fracture zone height in fully mechanized top-coal caving[J]. Coal Engineering, 2019, 51(S1): 56-59. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ2019S1014.htm [28] 高保彬, 王晓蕾, 朱明礼, 等. 复合顶板高瓦斯厚煤层综放工作面覆岩"两带"动态发育特征[J]. 岩石力学与工程学报, 2012, 31(S1): 3444-3451. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2012S1113.htmGao Baobin, Wang Xiaolei, Zhu Mingli, et al. Dynamic development characteristics of two zones of overburden strata under conditions of compound roof, highly gassy and thick coal seam in full-mechanized top coal caving faces[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(S1): 3444-3451. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2012S1113.htm [29] 孙亚军, 徐智敏, 董青红. 小浪底水库下采煤导水裂隙发育监测与模拟研究[J]. 岩石力学与工程学报, 2009, 28(2): 238-245. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200902005.htmSun Yajun, Xu Zhimin, Dong Qinghong. Monitoring and simulation research on development of water flowing fractures for coal mining under xiaolangdi reservoir[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(2): 238-245. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200902005.htm [30] 张安斌, 赵健, 张鹏, 等. 巨厚松散层下导水裂隙带高度预测试验探究[J]. 中国煤炭, 2016, 42(3): 28-33. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGME201603008.htmZhang Anbin, Zhao Jian, Zhang Peng, et al. Experimental study on height prediction of water conducted zone under extremely thick unconsolidated layer[J]. China Coal, 2016, 42(3): 28-33. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGME201603008.htm [31] 张通, 袁亮, 赵毅鑫, 等. 薄基岩厚松散层深部采场裂隙带几何特征及矿压分布的工作面效应[J]. 煤炭学报, 2015, 40(10): 2260-2268. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201510005.htmZhang Tong, Yuan Liang, Zhao Yixin, et al. Distribution law of working face pressure under the fracture zone distribution characteristic of deep mining[J]. Journal of China Coal Society, 2015, 40(10): 2260-2268. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201510005.htm [32] 陈俊杰. 风积沙区高强度开采覆岩与地表变形机理及特征研究[D]. 焦作: 河南理工大学, 2015. [33] 张宏伟, 朱志洁, 霍丙杰, 等. 基于改进的FOA-SVM导水裂隙带高度预测研究[J]. 中国安全科学学报, 2013, 23(10): 9-14. https://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK201310002.htmZhang Hongwei, Zhu Zhijie, Huo Bingjie, et al. Water Flowing Fractured Zone Height Prediction Based on Improved FOA-SVM[J]. China Safety Science Journal, 2013, 23(10): 9-14. https://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK201310002.htm [34] 余学义, 王昭舜, 杨云, 等. 大采深综放开采覆岩移动规律离散元数值模拟研究[J]. 采矿与岩层控制工程学报, 2021, 3(1): 28-38. https://www.cnki.com.cn/Article/CJFDTOTAL-MKKC202101002.htmYu Xueyi, Wang Zhaoshun, Yang Yun, et al. Numerical study on the movement rule of overburden in fully mechanized caving mining with thick depth and high mining height[J]. Journal of Mining and Strata Control Engineering, 2021, 3(1): 28-38. https://www.cnki.com.cn/Article/CJFDTOTAL-MKKC202101002.htm [35] Zhao X D, Jiang J, Lan B C. An integrated method to calculate the spatial distribution of overburden strata failure in longwall mines by coupling GIS and FLAC3D[J]. International Journal of Mining Science and Technology, 2015, 25(3): 369-373. -

下载:

下载: