Parameter optimization of alkali injection prevention and field application in coal seam of high hydrogen sulfide roadway

-

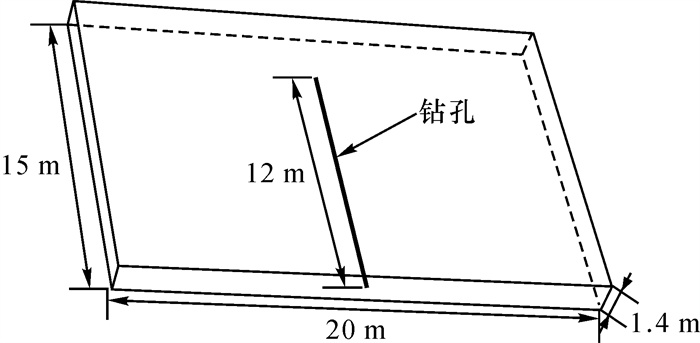

摘要: 煤矿井下硫化氢超限不但伤害作业人员,也会损坏井下设备。山西某煤矿巷道内水中硫化氢浓度为228.19 mg/m3,空气中硫化氢浓度为45.64 mg/m3,属于高硫化氢煤矿,拟采用煤层钻孔注碱的方法治理硫化氢。为确定最佳注碱参数,本文采用COMSOL Multiphysics软件对煤层注碱治理硫化氢的过程及效果开展单孔和双孔注碱数值模拟。结果表明:距离钻孔中心越远,煤层所受到的注碱压力越小;注碱时间越长,碱液的扩散范围越大,碱液的扩散速度随扩散范围的变大而逐渐减小;双孔注碱距离过近时,串流现象导致相同时间下碱液扩散范围变小;得出模拟最优方案为:孔距10 m、压力8 MPa、注碱时间48 h。在13103工作面注碱后,进行了为期28 d的现场数据监测,测得回风流硫化氢浓度最高为9.13 mg/m3,回采中未超限,表明最佳注碱参数可指导煤层注碱工作。Abstract: Exceeding the limit of underground hydrogen sulfide not only harms operators, but also damages underground equipment.The concentration of hydrogen sulfide in water in a coal mine roadway in Shanxi is 228.19 mg/m3, and 45.64 mg/m3in the air, rendering it a high hydrogen sulfide coal mine.The method of coal seam drilling and alkali injection is used to control hydrogen sulfide.In order to determine the optimal parameters of alkali injection, this paper uses COMSOL Multiphysics software to carry out single-hole and double-hole alkali injection numerical simulations on the process and effect of coal seam alkali injection to treat hydrogen sulfide.The simulation results of single-hole and double-hole alkali injection show that: the farther away from the drilling center, the lower the alkali injection pressure on the coal seam.The longer the alkali injection time, the larger the diffusion range of the alkali solution.And the diffusion speed of the alkali solution gradually decreases as the diffusion range becomes larger.When the distance of double-hole alkali injection is too close, the cross-flow will cause the diffusion range of the alkali solution to become smaller at the same time.The optimal simulation scheme is as follows: the hole distance is 10 m, the pressure is 8 MPa, and the alkali injection time is 48 h.After alkali injection at the 13103 working face, a 28 d on-site data monitoring was carried out.The maximum hydrogen sulfide concentration in the return air flow was 9.13 mg/m3, which did not exceed the limit during the mining, indicating that the optimal alkali injection parameters can guide the coal seam alkali injection work.

-

表 1 模型计算参数

Table 1. Model calculation parameters

变量 物理含义 参数值 μ 碱液动力黏度/(Pa·s) 1.005×10-3 εp 煤体孔隙率/% 1.94 ρ 碱溶液密度/(kg·m-3) l.0x103 p 最初注碱压力/MPa 4/5/6/7/8 k 煤体渗透率/mD 4.47×10-13 cH2S 煤层中硫化氢摩尔浓度/(mol·m-3) 5.8 cNa2CO3 碱液摩尔浓度/(mol·m-3) 58.1 Di 反应物扩散系数/(m2·m-1) 1.0×10-13 A 频度因子/(m3·mol·s-1) 1.0×10-6 E 活化能/(J·mol-1) 7.2×104 Rg 气体状态常数/J·(mol·K)-1 8.341 p0 煤层气体压力/MPa 0.26 T 温度/K 298.15 -

[1] Jin S Q, Ding Y M, Yan A H, et al. H2S management in 15# coal seam of Fenghuangshan coal mines[J]. Procedia Engineering, 2011, 26: 1490-1494. doi: 10.1016/j.proeng.2011.11.2329 [2] Mei Kaiyuan, Cheng Xiaowei, Gu Tao, et al. Effects of Fe and Al ions during hydrogen sulphide (H2S)-induced corrosion of tetracalcium aluminoferrite (C4AF) and tricalcium aluminate (C3A)[J]. Journal of Hazardous Materials, 2020: 123928. [3] 刘明举, 李国旗, Hani Mitri, 等. 煤矿硫化氢气体成因类型探讨[J]. 煤炭学报, 2011, 36(6): 978-983. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201106018.htmLiu Mingju, Li Guoqi, Hani Mitri, et al. Genesis modes discussion of H2S gas in coal mines[J]. Journal of China Coal Society, 2011, 36(6): 978-983. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201106018.htm [4] 魏俊杰, 邓奇根, 刘明举. 煤矿硫化氢的危害与防治[J]. 煤炭技术, 2014, 33(10): 269-272. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201410107.htmWei Junjie, Deng Qigen, Liu Mingju. Hazards of hydrogen sulfide and control measures in coal mines[J]. Coal Technology, 2014, 33(10): 269-272. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201410107.htm [5] 崔中杰, 傅雪海, 刘文平, 等. 煤矿瓦斯中H2S的成因危害与防治[J]. 煤矿安全, 2006, 37(9): 45-47. doi: 10.3969/j.issn.1003-496X.2006.09.016Cui Zhongjie, Fu Xuehai, Liu Wenping, et al. hazards and prevention of H2S in coal mine gas[J]. Safety in Coal Mines, 2006, 37(9): 45-47. doi: 10.3969/j.issn.1003-496X.2006.09.016 [6] 郭保国. 井筒过膏层硫化氢气体的防治[J]. 煤炭技术, 2003, 22(12): 57-58. doi: 10.3969/j.issn.1008-8725.2003.12.036Guo Baoguo. Prevention and control of Hydrogen Sulfide Gas in wellbore passing paste layer[J]. Coal Technology, 2003, 22(12): 57-58. doi: 10.3969/j.issn.1008-8725.2003.12.036 [7] 林海, 王亚楠, 韦威, 等. 芬顿试剂处理煤矿矿井水中硫化氢技术[J]. 煤炭学报, 2012, 37(10): 1760-1764. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201210034.htmLin Hai, Wang Yanan, Wei Wei, et al. Treatment of H2S in mine water using Fenton reagent[J]. Journal of China Coal Society, 2012, 37(10): 1760-1764. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201210034.htm [8] 张戈. 喷洒吸收液治理支架放煤涌出硫化氢实验研究[J]. 煤矿安全, 2016, 47(5): 57-60, 65. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201605015.htmZhang Ge. Experimental study on controlling hydrogen sulphide gushing by spraying absorption liquid during coal caving support[J]. Safety in Coal Mines, 2016, 47(5): 57-60, 65. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201605015.htm [9] 汪伟, 贾宝山, 祁云. 风幕封闭的综掘面硫化氢治理技术研究与应用[J]. 中国安全科学学报, 2020, 30(1): 73-80. https://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK202001013.htmWang Wei, Jia Baoshan, Qi Yun. Research and application of hydrogen sulfide control technology with enclosed air curtain in fully-mechanized excavation face[J]. China Safety Science Journal, 2020, 30(1): 73-80. https://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK202001013.htm [10] Daraee Maryam, Ghasemy Ebrahim, Rashidi Alimorad. Effective adsorption of hydrogen sulfide by intercalation of TiO2 and N-doped TiO2 in graphene oxide[J]. Journal of Environmental Chemical Engineering, 2020, 8(4): 1-10. [11] 高鑫浩. 乌东矿煤层硫化氢赋存规律及其防治技术研究[D]. 北京: 煤炭科学研究总院, 2020. [12] 赵义胜, 张崇智. 西曲矿9号煤H2S气体治理[J]. 煤炭科学技术, 2011, 39(S1): 26-29. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ2011S1014.htmZhao Yisheng, Zhang Chongzhi. H2S gas control of Xiqu mine No. 9 coal seam[J]. Coal Science and Technology, 2011, 39(S1): 26-29. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ2011S1014.htm [13] 孙维吉, 袁欣鹏, 梁冰, 等. 煤层注NaHCO3溶液防治H2S方法及效果研究[J]. 中国安全科学学报, 2016, 26(1): 104-108. https://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK201601019.htmSun Weiji, Yuan Xinpeng, Liang Bing, et al. Injecting NaHCO3 solution into coal seam to control hydrogen sulfide: method and effects[J]. China Safety Science Journal, 2016, 26(1): 104-108. https://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK201601019.htm [14] Zhang C, Wang X L, Liu H, et al. Development and application of modified lye for treating hydrogen sulphide in coal mine[J]. Fuel, 2020, 269: 117233. doi: 10.1016/j.fuel.2020.117233 [15] 傅献彩, 沈文霞, 姚天扬. 物理化学[M]. 北京: 高等教育出版社, 2004. [16] 戚斐文. 小庄矿煤层注碱治理硫化氢涌出危害研究[D]. 西安: 西安科技大学, 2019. [17] 梁冰, 袁欣鹏, 孙维吉, 等. 煤层注碱治理硫化氢数值模拟与应用[J]. 中国矿业大学学报, 2017, 46(2): 244-249. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201702003.htmLiang Bing, Yuan Xinpeng, Sun Weiji, et al. Numerical simulation of lye injection into coal seams for governance of H2S and its field applications[J]. Journal of China University of Mining & Technology, 2017, 46(2): 244-249. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201702003.htm [18] 陈国灿. 带有裂缝的多孔介质流动问题的数值模拟[D]. 贵阳: 贵州大学, 2019. [19] Warren J E, Root P J. The behavior of naturally fractured reservoirs[J]. Society of Petroleum Engineers Journal, 1963, 3(3): 245-255. doi: 10.2118/426-PA [20] 刘军文, 施安峰, 王晓宏, 等. 多孔介质结构对渗流惯性效应的影响规律研究[J]. 力学季刊, 2019, 40(3): 447-457. https://www.cnki.com.cn/Article/CJFDTOTAL-SHLX201903003.htmLiu Junwen, Shi Anfeng, Wang Xiaohong, et al. Study on influences of porous medium structure on inertial effect of seepage flow[J]. Chinese Quarterly of Mechanics, 2019, 40(3): 447-457 https://www.cnki.com.cn/Article/CJFDTOTAL-SHLX201903003.htm [21] 邵建立, 周斐, 薛彦超, 等. 岩体孔隙-裂隙双渗流数值模拟研究[J]. 煤矿安全, 2019, 50(9): 1-4. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201909001.htmShao Jianli, Zhou Fei, Xue Yanchao, et al. Study on numerical simulation of pore-fracture double seepage in rock mass[J]. Safety in Coal Mines, 2019, 50(9): 1-4. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201909001.htm -

下载:

下载: