Effects of dip angle and length of open joints on dynamic properties of materials like rock

-

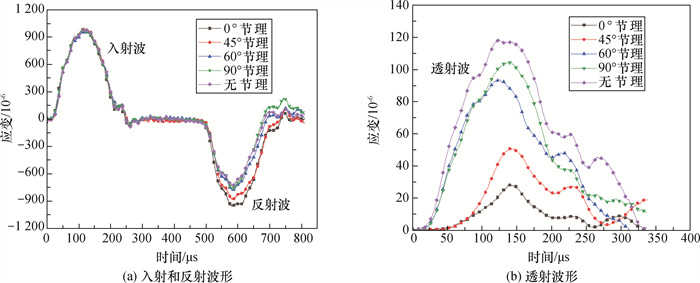

摘要: 为探究冲击荷载作用下张开型节理对类岩石材料动态力学特性的影响,基于分离式霍普金森压杆实验装置(SHPB),研究完整试件和含不同角度和长度节理的水泥砂浆试件在动荷载下的应力波传播特征、峰值承载力、破坏形态,分析讨论了基于能量理论的损伤规律。结果表明:试件会形成一组沿轴向与节理面贯通的张拉裂纹面和一组几乎平行于试件端面的裂纹面;节理长度由5 mm增大到30 mm时,应力波的反射作用越明显,试件的峰值承载力越小,破坏产生的裂纹面越小,因而损伤也越小。当节理角度从0°增至90°时,应力波的反射作用越小,损伤越小;峰值承载力随节理角度增大先减小后增大,当节理角度为60°时,峰值承载力最小,当节理角度为90°时,峰值承载力最大。Abstract: In order to investigate the influence of tensioned joints on the dynamic mechanical properties of rock-like materials under impact loading, investigated the stress wave propagation characteristics, peak bearing capacity, damage pattern and damage law based on energy theory under dynamic loading for intact specimens and cement mortar specimens containing joints of different angles and lengths with the help of a split Hopkinson compression bar device.The results show that the specimens will be damaged by forming a set of tensile cracking surfaces along the axial direction through the joint surface and a set of cracking surfaces almost parallel to the end face of the specimen.Under the experimental loading rate, when the joint length increases from 5 mm to 30 mm, the more obvious the reflection effect on the wave, the smaller the peak bearing capacity of the specimen, and the smaller the damage.When the joint angle increases from 0° to 90°, the smaller the reflection effect on the stress wave, and the smaller the damage value of the specimen.The peak bearing capacity of the specimen decreases with the increase of the joint angle and then increases.When the joint angle is 60°, the peak bearing capacity of the specimen reaches the minimum, and when the joint angle is 90°, the peak bearing capacity of the specimen reaches the maximum.

-

Key words:

- joints /

- impact loading /

- stress waves /

- energy dissipation /

- damage factor /

- rock dynamics

-

表 1 试件的物理力学参数

Table 1. Physical and mechanical parameters of test piece

密度ρ/ (g·cm-3) 弹性模量E/MPa 单轴抗压强度σ0/MPa 泊松比μ 黏聚力c/MPa 1.97 27.2 32.6 0.23 1.97 表 2 含不同长度、角度节理试件的各能量比

Table 2. The energy ratios of joint specimens with different lengths and angles

节理长度/mm 节理角度/ (°) 入射能EI/J 反射能量比ER/EI 透射能量比ET/EI 能量耗散比ED/EI 试验值/% 平均值/% 试验值/% 平均值/% 试验值/% 平均值/% 无 无 416.26 47.25 44.82 33.44 37.74 19.31 17.44 407.11 42.20 41.87 15.93 321.48 44.43 39.02 16.55 374.18 45.42 36.61 17.97 5 45 163.82 62.48 59.97 14.91 17.20 22.61 22.83 244.27 55.08 20.91 24.01 309.11 65.02 16.93 18.05 445.44 57.31 16.05 26.64 10 0 163.82 50.21 48.79 32.91 33.20 16.88 18.01 244.27 46.16 33.92 19.92 309.11 47.04 33.93 19.03 445.44 51.74 32.05 16.21 10 45 195.04 58.91 64.41 12.47 11.47 28.62 24.12 302.58 65.09 9.46 25.45 441.00 69.23 3.1 27.67 208.38 64.42 8.84 26.74 10 60 184.36 70.44 72.73 6.7 6.47 22.86 20.83 131.93 71.25 8.3 20.45 333.85 71.99 6.12 21.89 401.85 77.25 4.63 18.12 10 90 163.96 57.78 60.97 25.11 21.70 17.11 17.33 174.35 64.08 18.56 17.36 239.64 63.90 18.39 17.71 92.22 58.13 24.73 17.14 20 45 184.36 73.73 72.94 9.7 8.44 16.57 18.63 131.93 76.26 8.3 15.44 333.85 74.18 6.12 19.70 401.85 67.57 9.63 22.8 30 45 163.96 78.59 76.78 3.11 4.25 18.30 18.97 174.35 75.35 4.56 20.09 239.64 73.69 6.39 19.92 92.22 79.50 2.93 17.57 -

[1] Pyrak-Nolte L J. The seismic response of fractures and the interrelations among fracture properties[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1996, 33(8): 787-802. [2] Cai J G, Zhao J. Effects of multiple parallel fractures on apparent attenuation of stress waves in rock masses[J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37(4): 661-682. doi: 10.1016/S1365-1609(00)00013-7 [3] 刘丹, 黄曼, 洪陈杰, 等. 基于代表性取样的节理岩体抗压强度尺寸效应试验研究[J]. 岩石力学与工程学报, 2021, 40(4): 766-776. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202104010.htmLiu Dan, Huang Man, Hong Chenjie, et al. Experimental study on size effect of compressive strength of jointed rock mass based on representative sampling[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(4): 766-776. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202104010.htm [4] 武宇, 刘殿书, 吴帅峰, 等. 砂岩冲击损伤与应力波参数关系试验研究[J]. 矿业科学学报, 2018, 3(3): 229-237. http://kykxxb.cumtb.edu.cn/article/id/142Wu Yu, Liu Dianshu, Wu Shuaifeng, et al. Experimental study on relationship between impact damage of sandstone and stress wave parameters[J]. Journal of Mining Science and Technology, 2018, 3(3): 229-237. http://kykxxb.cumtb.edu.cn/article/id/142 [5] 周喆, 张亮, 侯恒军. 填充对节理岩体力学特性及能量演化的影响研究[J]. 水利水电技术, 2020, 51(7): 117-123. https://www.cnki.com.cn/Article/CJFDTOTAL-SJWJ202007015.htmZhou Zhe, Zhang Liang, Hou Hengjun. Study on impact from filling on mechanical properties and energy evolution of jointed rock mass[J]. Water Resources and Hydropower Engineering, 2020, 51(7): 117-123. https://www.cnki.com.cn/Article/CJFDTOTAL-SJWJ202007015.htm [6] 钟助. 裂隙岩体边坡岩桥破坏机制及稳定性研究[D]. 重庆: 重庆大学, 2019. [7] 王培涛, 黄正均, 任奋华, 等. 基于3D打印的含复杂节理岩石直剪特性及破坏机制研究[J]. 岩土力学, 2020, 41(1): 46-56. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202001007.htmWang Peitao, Huang Zhengjun, Ren Fenhua, et al. Study on direct shear characteristics and failure mechanism of rock with complex joints based on 3D printing[J]. Rock and Soil Mechanics, 2020, 41(1): 46-56. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202001007.htm [8] 陈淼. 断续节理岩体破坏力学特性及锚固控制机理研究[D]. 徐州: 中国矿业大学, 2019. [9] 凌天龙, 刘殿书, 梁书锋, 等. 花岗岩损伤型黏弹性动态本构模型研究[J]. 矿业科学学报, 2019, 4(5): 403-409. http://kykxxb.cumtb.edu.cn/article/id/239Ling Tianlong, Liu Dianshu, Liang Shufeng, et al. Research on damage viscoelastic dynamic constitutive model of granite[J]. Journal of Mining Science and Technology, 2019, 4(5): 403-409. http://kykxxb.cumtb.edu.cn/article/id/239 [10] 李胜林, 凌天龙, 张会歌, 等. 早龄期混凝土动态力学性能实验研究[J]. 矿业科学学报, 2020, 5(5): 502-510. doi: 10.19606/j.cnki.jmst.2020.05.004Li Shenglin, Ling Tianlong, Zhang Huige, et al. Experimental research on dynamic mechanics of early age concrete[J]. Journal of Mining Science and Technology, 2020, 5(5): 502-510. doi: 10.19606/j.cnki.jmst.2020.05.004 [11] 李成孝, 张渊通, 安晨. 单侧开半圆孔PMMA试件Ⅰ型和Ⅰ-Ⅱ混合型裂纹动态扩展及数值模拟研究[J]. 矿业科学学报, 2020, 5(5): 490-501. doi: 10.19606/j.cnki.jmst.2020.05.003Li Chengxiao, Zhang Yuantong, An Chen. Study on the dynamic propagation and numerical simulation of mode Ⅰ and mixed mode Ⅰ-Ⅱ cracks in PMMA specimens with unilateral semicircular holes[J]. Journal of Mining Science and Technology, 2020, 5(5): 490-501. doi: 10.19606/j.cnki.jmst.2020.05.003 [12] Li J C, Ma G W. Experimental study of stress wave propagation across a filled rock joint[J]. International Journal of Rock Mechanics and Mining Sciences, 2009, 46(3): 471-478. doi: 10.1016/j.ijrmms.2008.11.006 [13] 刘红岩, 邓正定, 王新生, 等. 节理岩体动态破坏的SHPB相似材料试验研究[J]. 岩土力学, 2014, 35(3): 659-665. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201403009.htmLiu Hongyan, Deng Zhengding, Wang Xinsheng, et al. Similar material test study of dynamic failure of jointed rock mass with SHPB[J]. Rock and Soil Mechanics, 2014, 35(3): 659-665. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201403009.htm [14] 杨仁树, 王茂源, 杨阳, 等. 充填材料对节理岩石动力学性能影响的模拟试验[J]. 振动与冲击, 2016, 35(12): 125-131. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201612019.htmYang Renshu, Wang Maoyuan, Yang Yang, et al. Simulation material experiment on the dynamic mechanical properties of jointed rock affected by joint-filling material[J]. Journal of Vibration and Shock, 2016, 35(12): 125-131. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201612019.htm [15] 鞠杨, 李业学, 谢和平, 等. 节理岩石的应力波动与能量耗散[J]. 岩石力学与工程学报, 2006, 25(12): 2426-2434. doi: 10.3321/j.issn:1000-6915.2006.12.007Ju Yang, Li Yexue, Xie Heping, et al. Stress wave propagation and energy dissipation in jointed rocks[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(12): 2426-2434. doi: 10.3321/j.issn:1000-6915.2006.12.007 [16] 李祥龙, 王建国, 张智宇, 等. 应变率及节理倾角对岩石模拟材料动力特性的影响[J]. 爆炸与冲击, 2016, 36(4): 483-490. https://www.cnki.com.cn/Article/CJFDTOTAL-BZCJ201604007.htmLi Xianglong, Wang Jianguo, Zhang Zhiyu, et al. Experimental study for effects of strain rates and joint angles on dynamic responses of simulated rock materials[J]. Explosion and Shock Waves, 2016, 36(4): 483-490. https://www.cnki.com.cn/Article/CJFDTOTAL-BZCJ201604007.htm [17] 杨阳, 杨仁树, 王建国. 节理厚度对岩石动力特性影响的模拟试验[J]. 中国矿业大学学报, 2016, 45(2): 211-216, 309. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201602003.htmYang Yang, Yang Renshu, Wang Jianguo. Simulation material experiment on dynamic mechanical properties of jointed rock affected by joint thickness[J]. Journal of China University of Mining & Technology, 2016, 45(2): 211-216, 309. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201602003.htm [18] 张伟, 周国庆, 张海波, 等. 倾角对裂隙岩体力学特性影响试验模拟研究[J]. 中国矿业大学学报, 2009, 38(1): 30-33. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD200901008.htmZhang Wei, Zhou Guoqing, Zhang Haibo, et al. Experimental research on the influence of obliquity on the mechanical characteristics of a fractured rock mass[J]. Journal of China University of Mining & Technology, 2009, 38(1): 30-33. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD200901008.htm [19] 王建国, 高全臣, 陆华, 等. 分层介质冲击响应的SHPB实验研究[J]. 振动与冲击, 2015, 34(19): 192-197, 212. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201519031.htmWang Jianguo, Gao Quanchen, Lu Hua, et al. Impact response tests of layered medium with SHPB[J]. Journal of Vibration and Shock, 2015, 34(19): 192-197, 212. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201519031.htm [20] 王建国, 梁书锋, 高全臣, 等. 节理倾角对类岩石冲击能量传递影响的试验研究[J]. 中南大学学报: 自然科学版, 2018, 49(5): 1237-1243. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201805027.htmWang Jianguo, Liang Shufeng, Gao Quanchen, et al. Experimental study of jointed angles impact on energy transfer characteristics of simulated rock material[J]. Journal of Central South University: Science and Technology, 2018, 49(5): 1237-1243. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201805027.htm [21] 杨国梁, 毕京九, 张志飞, 等. 被动围压下层理角度对页岩动态强度及耗能的影响[J]. 矿业科学学报, 2021, 6(2): 188-195. doi: 10.19606/j.cnki.jmst.2021.02.006Yang Guoliang, Bi Jingjiu, Zhang Zhifei, et al. The influence of the bedding angle under passive confining pressure on the dynamic strength and energy consumption of shale[J]. Journal of Mining Science and Technology, 2021, 6(2): 188-195. doi: 10.19606/j.cnki.jmst.2021.02.006 [22] 王卫华, 李夕兵, 周子龙, 等. 不同应力波在张开节理处的能量传递规律[J]. 中南大学学报: 自然科学版, 2006, 37(2): 376-380. doi: 10.3969/j.issn.1672-7207.2006.02.032Wang Weihua, Li Xibing, Zhou Zilong, et al. Energy-transmitted rule of various stress waves across open joint[J]. Journal of Central South University: Science and Technology, 2006, 37(2): 376-380. doi: 10.3969/j.issn.1672-7207.2006.02.032 [23] Fourney W L, Dick R D, Fordyce D F, et al. Effects of open gaps on particle velocity measurements[J]. Rock Mechanics and Rock Engineering, 1997, 30(2): 95-111. doi: 10.1007/BF01020127 [24] Wu Y K, Hao H, Zhou Y X, et al. Propagation characteristics of blast-induced shock waves in a jointed rock mass[J]. Soil Dynamics and Earthquake Engineering, 1998, 17(6): 407-412. doi: 10.1016/S0267-7261(98)00030-X [25] Shan R L, Jiang Y S, Li B Q. Obtaining dynamic complete stress-strain curves for rock using the Split Hopkinson Pressure Bar technique[J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37(6): 983-992. [26] Frew D J, Forrestal M J, Chen W. A split Hopkinson pressure bar technique to determine compressive stress-strain data for rock materials[J]. Experimental Mechanics, 2001, 41(1): 40-46. -

下载:

下载: