Evolution characteristics of elastic energy storage of marble under creep loading

-

摘要: 为研究蠕变过程中大理岩对能量的吸收转化特征和应变能的释放与耗散机理,测试分析了大理岩在单轴循环加载和多级蠕变循环加载条件下的应力-应变关系,计算得到各自的弹性能密度曲线,采用幂函数拟合了大理岩弹性能密度与应力之间的关系。对比两种加载方式的测试数据,结果表明:单轴循环加载和多级蠕变循环加载试验的弹性能密度曲线基本重合,即加载模式不影响大理岩的弹性能密度变化特征;两种加载模式下大理岩材料都经历压密、稳定和劣化三个阶段。经历蠕变循环加载之后的大理岩试样,弹性储能能力会降低,约为单轴循环加载的43 %;强度也有明显下降,约为单轴循环加载的62 %。如果考虑长期承载问题,大理岩的最大应力值应控制在材料的压密阶段结束点对应的应力以下较为有利。Abstract: In order to study the energy absorption and transformation characteristics of marble, the release of strain energy and dissipation mechanism during creep process, this paper tested the stress-strain relationship of marble under uniaxial cyclic loading and multi-level creep cyclic loading respectively, and calculated their elastic energy density curves.The power function is used to fit the relationship between elastic energy density and stress of marble.By comparing the test data of the two loading modes, the results showed that the elastic energy density curves of uniaxial cyclic loading and multi-level creep cyclic loading were basically coincident, and they have the same elastic energy density curves, which means neither the creep loading mode nor the uniaxial cyclic loading mode will affect the elastic energy density curve of the marble.Comparing the ratio of elastic energy to external power in two loading modes, the results showed that the marble materials all went through three stages: compaction, stabilization and deterioration.After creep cyclic loading, the elastic energy storage capacity of marble would decrease to 43 % of uniaxial cyclic loading.Correspondingly, its strength also decreased obviously, which was 62 % of uniaxial cyclic loading.If the long-term bearing issue of this kind of marble is taken into account, the maximum stress value should be controlled below the stress that corresponds to the end point of the compaction stage of material.

-

Key words:

- marble /

- creep loading /

- elastic energy density /

- elastic energy ratio

-

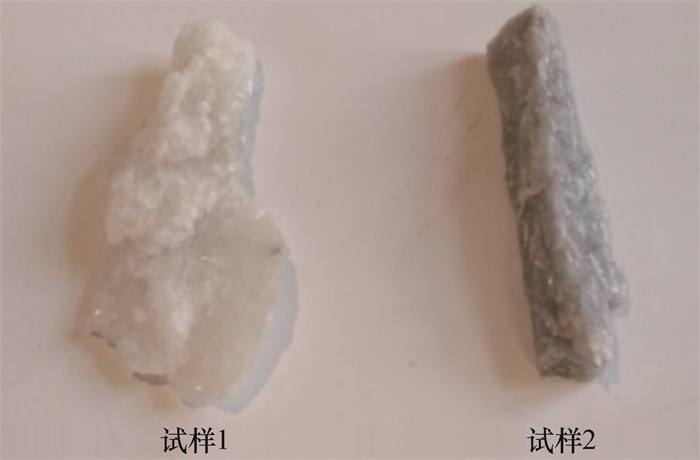

表 1 大理岩岩样X-射线衍射分析

Table 1. X-ray diffraction analysis of marble samples

岩样 颜色 矿物种类和含量/% 方解石 白云石 1 白色 100.0 — 2 灰色 93.0 7.0 表 2 单轴循环加卸载试验结果

Table 2. Test results of uniaxial loading and unloading cycles

试样编号 应力/ MPa 总外力功密度U/ (kJ·m-3) 弹性能密度Ue/ (kJ·m-3) 耗散能密度Ud/ (kJ·m-3) 弹性能比例K/% 试样编号 应力/ MPa 总外力功密度U/ (kJ·m-3) 弹性能密度Ue/ (kJ·m-3) 耗散能密度Ud/ (kJ·m-3) 弹性能比例K/% A1 2.53 0.34 0.17 0.17 50.26 A3 2.53 0.25 0.14 0.11 55.07 5.08 0.72 0.52 0.20 72.24 5.07 0.57 0.46 0.11 79.98 7.62 1.31 1.04 0.27 79.07 7.62 1.09 0.94 0.15 85.63 10.17 2.03 1.68 0.35 83.04 10.17 1.78 1.57 0.21 87.96 12.71 2.88 2.45 0.43 85.30 12.71 2.58 2.29 0.29 88.90 15.26 3.83 3.32 0.51 86.73 15.26 3.52 3.14 0.38 89.42 17.80 4.85 4.26 0.59 87.76 17.81 4.49 4.05 0.44 90.08 20.36 6.04 5.32 0.72 88.16 20.36 5.58 5.05 0.53 90.55 22.90 7.29 6.44 0.85 88.38 22.90 6.75 6.12 0.63 90.75 25.45 8.67 7.68 0.99 88.63 25.44 8.07 7.32 0.75 90.73 28.00 10.13 9.01 1.12 88.88 28.00 9.50 8.59 0.91 90.37 30.53 11.66 10.39 1.27 89.07 30.54 11.03 9.92 1.11 89.97 33.09 13.33 11.91 1.42 89.33 32.98 12.65 11.28 1.37 89.21 35.63 15.06 13.48 1.58 89.53 35.38 14.41 12.79 1.62 88.81 37.91 15.99 14.41 1.58 90.11 48.37 25.28 22.75 2.53 90.01 40.42 18.00 16.01 1.99 88.92 50.91 27.77 24.98 2.79 89.96 43.26 21.09 17.94 3.15 85.06 A2 2.52 0.22 0.16 0.06 72.23 A4 2.52 0.36 0.18 0.18 49.28 5.08 0.64 0.49 0.15 76.50 5.08 0.80 0.52 0.28 65.33 7.60 1.20 0.98 0.22 81.22 10.17 1.92 1.59 0.33 83.07 7.62 1.42 1.02 0.38 71.98 12.72 2.76 2.32 0.44 83.95 15.25 3.71 3.14 0.57 84.83 10.17 2.11 1.65 0.46 78.32 17.81 4.74 4.08 0.66 86.08 20.35 5.83 5.08 0.75 87.15 12.71 2.89 2.41 0.48 83.22 22.90 7.07 6.23 0.84 88.05 25.45 8.37 7.41 0.96 88.59 15.26 3.82 3.28 0.54 85.97 30.53 9.81 8.73 1.08 89.51 33.09 11.34 10.15 1.19 89.79 17.81 4.85 4.23 0.62 87.30 35.64 12.99 11.66 1.33 89.87 38.18 14.79 13.29 1.50 90.11 20.36 5.99 5.29 0.70 88.17 40.71 16.58 14.94 1.64 90.25 43.27 18.58 16.77 1.81 90.37 22.90 7.24 6.41 0.83 88.53 45.82 20.63 18.64 1.99 90.41 25.45 8.62 7.64 0.98 88.67 48.36 22.76 20.58 2.18 90.45 28.00 10.09 8.95 1.14 88.63 50.91 25.09 22.69 2.40 90.46 32.94 13.98 11.34 2.64 81.08 53.46 27.45 24.83 2.62 90.14 35.33 16.58 12.28 4.30 74.07 表 3 多级蠕变循环加卸载试验结果

Table 3. Test results of multi-level creep cyclic loading and unloading

试样编号 单次循环第一阶段 单次循环第二阶段 应力/ MPa 总外力功密度U/(kJ·m-3) 弹性能密度Ue1 /(kJ·m-3) 耗散能密度Ud/(kJ·m-3) 弹性能比例K/% 弹性能密度Ue2/(kJ·m-3) B1 3.39 0.45 0.23 0.22 51.33 0.21 6.67 0.85 0.72 0.13 84.56 0.74 10.09 1.66 1.49 0.17 90.19 1.50 13.49 2.67 2.43 0.24 91.07 2.47 17.30 4.07 3.75 0.32 91.98 3.77 20.20 5.26 4.86 0.40 92.39 4.93 23.57 6.78 6.25 0.53 92.09 6.40 26.93 8.81 8.00 0.81 90.81 8.17 B2 3.39 0.41 0.26 0.15 64.69 0.28 6.69 1.01 0.84 0.17 83.24 0.86 10.08 1.88 1.66 0.22 88.49 1.70 13.49 2.96 2.65 0.31 89.54 2.71 16.97 4.25 3.85 0.39 90.72 4.04 20.19 5.56 5.10 0.46 91.72 5.12 23.57 7.15 6.59 0.56 92.17 6.72 26.93 8.86 8.13 0.73 91.72 8.39 30.30 10.97 10.05 0.92 91.59 10.23 B3 3.39 0.51 0.26 0.25 50.48 0.25 6.69 1.01 0.81 0.20 80.40 0.82 10.08 1.83 1.58 0.25 86.55 1.60 13.49 2.88 2.56 0.32 88.79 2.59 16.79 4.04 3.64 0.40 90.00 3.62 19.79 5.22 4.73 0.49 90.61 4.76 23.18 6.73 6.14 0.59 91.20 6.17 26.99 8.71 7.88 0.83 90.53 7.99 29.99 10.44 9.48 0.96 90.72 9.60 B4 3.39 0.43 0.24 0.19 56.05 0.25 6.69 0.93 0.77 0.16 83.48 0.81 10.08 1.81 1.58 0.23 87.46 1.62 13.49 2.91 2.59 0.32 89.02 2.65 16.79 4.14 3.72 0.42 89.81 3.77 19.78 5.36 4.84 0.52 90.25 4.93 23.18 7.01 6.24 0.77 89.06 6.36 26.99 9.11 8.08 1.03 88.69 8.12 表 4 单轴循环加载拟合的参数a与b

Table 4. Fitting parameters a and b by uniaxial cyclic loading

试件编号 a b A1 0.032 1.69 A2 0.035 1.66 A3 0.027 1.74 A4 0.046 1.57 均值 0.035 1.70 标准差 0.007 0.03 表 5 蠕变循环加载拟合的参数a与b

Table 5. Fitting parameters a and b by creep cyclic loading

试件编号 a b B1 0.028 1.72 B2 0.036 1.65 B3 0.035 1.65 B4 0.035 1.65 均值 0.034 1.67 标准差 0.003 0.03 表 6 弹性能储能极限值

Table 6. Limit value of stored elastic energy

加载方式 编号 极限荷载/ kN 极限应力/ MPa 总外力功密度U/(kJ·m-3) 极限弹性能密度Ue/(kJ·m-3) 弹性能比例K/% 单轴循环加载 A1 99.96 50.91 27.77 24.98 89.96 A2 104.97 53.46 30.03 27.06 90.14 A3 84.94 43.26 21.09 17.94 85.06 A4 69.37 35.33 16.58 12.28 74.07 平均值 89.81 45.74 23.87 20.57 84.81 标准差 13.91 7.09 5.34 5.86 6.53 多级蠕变循环加载 B1 52.88 26.93 8.81 8.00 90.81 B2 59.49 30.30 10.97 10.05 91.59 B3 58.89 29.99 10.44 9.48 90.72 B4 52.99 26.99 9.11 8.08 88.69 均值 56.06 28.55 9.83 8.90 90.45 标准差 3.13 1.60 0.90 0.89 1.07 -

[1] 李慎奎. 武汉地区沙漏型岩溶塌陷数值分析与模型试验研究[J]. 隧道建设: 中英文, 2020, 40(7): 981-987. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD202007006.htmLi Shenkui. Numerical analysis and model test of hourglass-shaped Karst collapse in Wuhan area[J]. Tunnel Construction, 2020, 40(7): 981-987. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD202007006.htm [2] 刘之葵, 梁金城, 朱寿增, 等. 岩溶区含溶洞岩石地基稳定性分析[J]. 岩土工程学报, 2003, 25(5): 629-633. doi: 10.3321/j.issn:1000-4548.2003.05.024Liu Zhikui, Liang Jincheng, Zhu Shouzeng, et al. Stability analysis of rock foundation with cave in Karst area[J]. Chinese Journal of Geotechnical Engineering, 2003, 25(5): 629-633. doi: 10.3321/j.issn:1000-4548.2003.05.024 [3] 邓艺聪. 浅析岩溶地区高层建筑局部桩基缺陷对桩底岩石应力的影响[C]//第二十届全国现代结构工程学术研讨会论文集. 石家庄, 2020: 53-56. [4] 张志镇, 高峰. 单轴压缩下岩石能量演化的非线性特性研究[J]. 岩石力学与工程学报, 2012, 31(6): 1198-1207. doi: 10.3969/j.issn.1000-6915.2012.06.015Zhang Zhizhen, Gao Feng. Research on nonlinear characteristics of rock energy evolution under uniaxial compression[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(6): 1198-1207. doi: 10.3969/j.issn.1000-6915.2012.06.015 [5] 谢和平, 鞠杨, 黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则[J]. 岩石力学与工程学报, 2005, 24(17): 3003-3010. doi: 10.3321/j.issn:1000-6915.2005.17.001Xie Heping, Ju Yang, Li Liyun. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(17): 3003-3010. doi: 10.3321/j.issn:1000-6915.2005.17.001 [6] 赵忠虎, 谢和平. 岩石变形破坏过程中的能量传递和耗散研究[J]. 四川大学学报: 工程科学版, 2008, 40(2): 26-31. https://www.cnki.com.cn/Article/CJFDTOTAL-SCLH200802006.htmZhao Zhonghu, Xie Heping. Energy transfer and energy dissipation in rock deformation and fracture[J]. Journal of Sichuan University: Engineering Science Edition, 2008, 40(2): 26-31. https://www.cnki.com.cn/Article/CJFDTOTAL-SCLH200802006.htm [7] 谢和平, 彭瑞东, 鞠杨, 等. 岩石破坏的能量分析初探[J]. 岩石力学与工程学报, 2005, 24(15): 2603-2608. doi: 10.3321/j.issn:1000-6915.2005.15.001Xie Heping, Peng Ruidong, Ju Yang, et al. On energy analysis of rock failure[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(15): 2603-2608. doi: 10.3321/j.issn:1000-6915.2005.15.001 [8] He M M, Pang F, Wang H T, et al. Energy dissipation-based method for strength determination of rock under uniaxial compression[J]. Shock and Vibration, 2020, 2020: 1-13. [9] 张国凯, 李海波, 夏祥, 等. 岩石单轴压缩下能量与损伤演化规律研究[J]. 岩土力学, 2015, 36(S1): 94-100. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2015S1016.htmZhang Guokai, Li Haibo, Xia Xiang, et al. Research on energy and damage evolution of rock under uniaxial compression[J]. Rock and Soil Mechanics, 2015, 36(S1): 94-100. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2015S1016.htm [10] 彭瑞东, 谢和平, 鞠杨, 等. 试验机弹性储能对岩石力学性能测试的影响[J]. 力学与实践, 2005, 27(3): 51-55. doi: 10.3969/j.issn.1000-0879.2005.03.012Peng Ruidong, Xie Heping, Ju Yang, et al. Effect of elastic accumulation energy of testing machine on the mechanical measurement of rocks[J]. Mechanics and Engineering, 2005, 27(3): 51-55. doi: 10.3969/j.issn.1000-0879.2005.03.012 [11] Cao K, Ma L, Wu Y, et al. Using the characteristics of infrared radiation during the process of strain energy evolution in saturated rock as a precursor for violent failure[J]. Infrared Physics & Technology, 2020, 109: 103406. [12] Li J L, Hong L, Zhou K P, et al. Influence of loading rate on the energy evolution characteristics of rocks under cyclic loading and unloading[J]. Energies, 2020, 13(15): 1-16. [13] Zhang Y, Feng X T, Zhang X W, et al. Strain energy evolution characteristics and mechanisms of hard rocks under true triaxial compression[J]. Engineering Geology, 2019, 260: 105222. doi: 10.1016/j.enggeo.2019.105222 [14] Li D Y, Sun Z, Xie T, et al. Energy evolution characteristics of hard rock during triaxial failure with different loading and unloading paths[J]. Engineering Geology, 2017, 228: 270-281. doi: 10.1016/j.enggeo.2017.08.006 [15] Wang Y F, Cui F. Energy evolution mechanism in process of Sandstone failure and energy strength criterion[J]. Journal of Applied Geophysics, 2018, 154: 21-28. doi: 10.1016/j.jappgeo.2018.04.025 [16] 杨圣奇, 徐卫亚, 苏承东. 大理岩三轴压缩变形破坏与能量特征研究[J]. 工程力学, 2007, 24(1): 136-142. https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX200701022.htmYang Shengqi, Xu Weiya, Su Chengdong. Study on the deformation failure and energy properties of marble specimen under triaxial compression[J]. Engineering Mechanics, 2007, 24(1): 136-142. https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX200701022.htm [17] 杨国梁, 毕京九, 张志飞, 等. 被动围压下层理角度对页岩动态强度及耗能的影响[J]. 矿业科学学报, 2021, 6(2): 188-195. doi: 10.19606/j.cnki.jmst.2021.02.006Yang Guoliang, Bi Jingjiu, Zhang Zhifei, et al. The influence of the bedding angle under passive confining pressure on the dynamic strength and energy consumption of shale[J]. Journal of Mining Science and Technology, 2021, 6(2): 188-195. doi: 10.19606/j.cnki.jmst.2021.02.006 [18] 王超圣, 周宏伟, 裴浩, 等. 甘肃北山地区花岗岩破坏过程能量聚集和耗散特征研究[J]. 矿业科学学报, 2018, 3(6): 536-542. http://kykxxb.cumtb.edu.cn/article/id/182Wang Chaosheng, Zhou Hongwei, Pei Hao, et al. Study on energy concentration and dissipation of Beishan granite in Gansu during failure process[J]. Journal of Mining Science and Technology, 2018, 3(6): 536-542. http://kykxxb.cumtb.edu.cn/article/id/182 [19] 谢和平, 鞠杨, 黎立云, 等. 岩体变形破坏过程的能量机制[J]. 岩石力学与工程学报, 2008, 27(9): 1729-1740. doi: 10.3321/j.issn:1000-6915.2008.09.001Xie Heping, Ju Yang, Li Liyun, et al. Energy mechanism of deformation and failure of rock masses[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(9): 1729-1740. doi: 10.3321/j.issn:1000-6915.2008.09.001 -

下载:

下载: