Optimization of flotation reagent system of coal slime based on uniform experimental design

-

摘要: 为了研究浮选药剂制度对煤泥浮选的影响,以水峪选煤厂的煤泥为研究对象,基于均匀试验设计方法建立浮选效果与药剂用量之间的数学模型,考察捕收剂和起泡剂用量对浮选效果的影响。研究结果表明:捕收剂在一定的用量范围内,煤泥浮选效果只与起泡剂用量存在相关关系; 最佳的起泡剂用量为75 g/t,适宜的捕收剂用量为130 g/t; 与现场药剂用量捕收剂257 g/t和起泡剂143 g/t相比,在保证精煤灰分不变的情况下,浮选精煤产率提高0.49 %,可燃体回收率提高0.50 %,浮选完善指标提高0.17 %,捕收剂用量降低127 g/t,起泡剂用量降低68 g/t; 当捕收剂用量在一定范围内时,起泡剂用量是影响浮选效果的关键因素,适宜的起泡剂用量可显著提高煤泥分选效果。Abstract: In order to study the influence of flotation reagent system on coal slime flotation, the coal slime of Shuiyu Coal Washing Plant is taken as the research object.Based on the uniform experimental design(UED)method, the mathematical model between flotation effect and reagent dosage is established, and the effect of collector and frother dosage on flotation effect is investigated.The results show that the flotation effect of coal slime is only related to the amount of frother in a certain range of collector dosage; the optimal dosage of frother is 75 g/t, the appropriate dosage of collector is 130 g/t.Compared with the actual production dosage, under the conditions of 257 g/t collector and 143 g/t frother, and the ash content of clean coal kept unchanged, the yield of flotation clean coal is increased by 0.49 %, the combustible material recovery is increased by 0.50 %, the improvement index of flotation is increased by 0.17 %, the dosage of collector is reduced by 127 g/t, and the dosage of frother is reduced by 68 g/t.When the collector dosage is within a certain range, the frother dosage is the key factor affecting the flotation effect, and the appropriate frother dosage can significantly improve the coal slime separation effect.

-

表 1 煤样粒度组成

Table 1. Size analysis of coal sample

粒级/mm 产率/% 灰分/% 筛上累计/% 筛下累计/% 产率 灰分 产率 灰分 >0.5 0.00 0.00 0.00 0.00 100.00 20.28 0.5~0.3 2.65 16.78 2.65 16.78 100.00 20.28 0.3~0.125 17.99 11.76 20.63 12.40 97.35 20.37 0.125~0.076 16.93 10.31 37.57 11.46 79.37 22.33 0.076~0.038 19.05 14.48 56.61 12.48 62.43 25.58 < 0.038 43.39 30.46 100.00 20.28 43.39 30.46 合计 100.00 20.28 — — — — 表 2 煤样物相分析结果

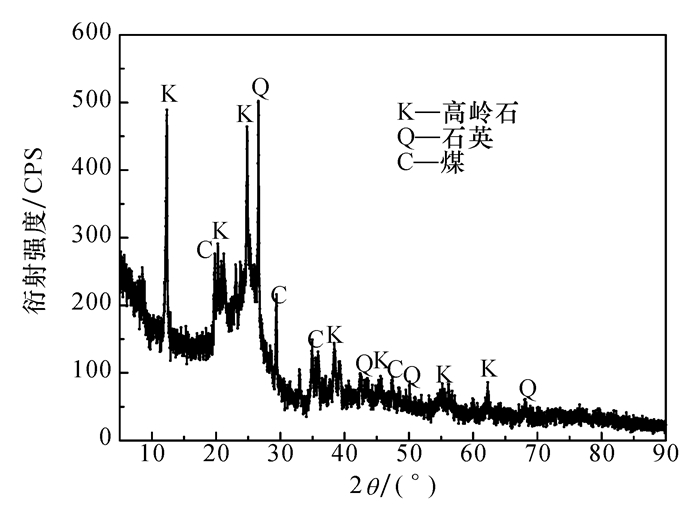

Table 2. Results of phase analysis of coal sample

矿物名称 高岭石 石英 合计 含量/% 69.93 30.07 100.00 表 3 U11*(114)均匀表及试验数据

Table 3. U11*(114)uniform table and test data

试验号 因素水平 浮选完善指标nwf/% A/(g·t-1) B/(g·t-1) A2 B2 AB A3 B3 A2B AB2 1 100 80 10000 6400 8000 1000000 512000 800000 640000 53.680 2 130 180 16900 32400 23400 2197000 5832000 3042000 4212000 49.279 3 160 40 25600 1600 6400 4096000 64000 1024000 256000 54.266 4 190 140 36100 19600 26600 6859000 2744000 5054000 3724000 51.650 5 220 0 48400 0 0 10648000 0 0 0 36.584 6 250 100 62500 10000 25000 15625000 1000000 6250000 2500000 51.847 7 280 200 78400 40000 56000 21952000 8000000 15680000 11200000 51.454 8 310 60 96100 3600 18600 29791000 216000 5766000 1116000 53.885 9 340 160 115600 25600 54400 39304000 4096000 18496000 8704000 52.717 10 370 20 136900 400 7400 50653000 8000 2738000 148000 51.008 11 400 120 160000 14400 48000 64000000 1728000 19200000 5760000 53.728 表 4 模型汇总

Table 4. Model summary

模型 R R2 调整后的R2 估计的标准误差 1 0.956 0.915 0.573 3.259 64 表 5 方差分析

Table 5. Anova of uniform design

平方和 自由度df 均方差 F 显著性水平S 回归 227.365 8 28.421 2.675 0.301 残差 21.252 2 10.626 — — 总离差 248.617 10 — — — 表 6 回归系数

Table 6. Coefficients of uniform design

因素 非标准化系数 标准误差 标准化系数 t值 显著性水平S 常数项 30.617 24.025 — 1.274 0.331 A 0.111 0.316 2.207 0.350 0.760 B 0.551 0.154 7.334 3.582 0.070 A2 -0.001 0.001 -5.827 -0.420 0.716 B2 -0.005 0.002 -14.383 -2.940 0.099 A3 1.008×10-6 0.000 4.287 0.535 0.646 B3 1.267×10-5 0.000 6.882 2.067 0.175 A2B -9.773×10-7 0.000 -1.412 -0.787 0.514 AB2 2.331×10-6 0.000 1.755 0.761 0.526 表 7 模型汇总

Table 7. Model summary

模型 R R2 调整后的R2 估计的标准误差 2 0.911 0.830 0.757 2.458 77 表 8 方差分析

Table 8. Anova of uniform design

平方和 自由度df 均方差 F 显著性水平S 回归 206.298 3 68.766 11.375 0.004 残差 42.319 7 6.046 — — 总离差 248.617 10 — — — 表 9 回归系数

Table 9. Coefficients of uniform design

因素 非标准化系数 标准误差 标准化系数 t值 显著性水平S 常数项 39.182 2.186 — 17.926 0.000 B 0.504 0.100 6.703 5.063 0.001 B2 -0.005 0.001 -13.331 -4.049 0.005 B3 1.314×10-5 0.000 7.140 3.361 0.012 -

[1] Wen B F, Xia W C, Sokolovic J M.Recent advances in effective collectors for enhancing the flotation of low rank/oxidized coals[J]. Powder Technology, 2017, 319: 1-11. doi: 10.1016/j.powtec.2017.06.030 [2] Wang G C, Bai X T, Wu C N, et al. Recent advances in the beneficiation of ultrafine coal particles[J]. Fuel Processing Technology, 2018, 178: 104-125. doi: 10.1016/j.fuproc.2018.04.035 [3] 徐东方, 朱书全, 朱志波, 等. 六偏磷酸钠对浮选中煤泥与黏土颗粒间相互作用的影响[J]. 矿业科学学报, 2016, 1(3): 269-276. http://kykxxb.cumtb.edu.cn/CN/abstract/abstract37.shtmlXu Dongfang, Zhu Shuquan, Zhu Zhibo, et al. Influences of sodium hexametaphosphate on interactions of coal and clay particles in flotation[J]. Journal of Mining Science and Technology, 2016, 1(3): 269-276. http://kykxxb.cumtb.edu.cn/CN/abstract/abstract37.shtml [4] 程晨, 宋杨, 杨博, 等. 氧化钙强化高硫细煤泥浮选试验研究[J]. 贵州大学学报: 自然科学版, 2020, 37(5): 54-60. https://www.cnki.com.cn/Article/CJFDTOTAL-GZDI202005009.htmCheng Chen, Song Yang, Yang Bo, et al. Flotation performance of a high-sulfur coal fine enhanced by calcium oxide[J]. Journal of Guizhou University: Natural Sciences, 2020, 37(5): 54-60. https://www.cnki.com.cn/Article/CJFDTOTAL-GZDI202005009.htm [5] 张志军, 李亚南, 佟震阳, 等. 高岭石对金属阳离子的吸附特性研究[J]. 矿业科学学报, 2017, 2(3): 294-300. http://kykxxb.cumtb.edu.cn/CN/abstract/abstract76.shtmlZhang Zhijun, Li Yanan, Tong Zhenyang, et al. Adsorption characteristics of metal ions on kaolinite[J]. Journal of Mining Science and Technology, 2017, 2(3): 294-300. http://kykxxb.cumtb.edu.cn/CN/abstract/abstract76.shtml [6] 崔广文, 于文慧, 张玉, 等. 煤泥浮选药剂研究现状及发展趋势[J]. 洁净煤技术, 2015, 21(1): 15-19. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201501006.htmCui Guangwen, Yu Wenhui, Zhang Yu, et al. Status and development trend of coal slime flotation reagents[J]. Clean Coal Technology, 2015, 21(1): 15-19. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201501006.htm [7] 邓丽君, 曹亦俊, 王利军. 起泡剂溶液的表面张力对气泡尺寸的影响[J]. 中国科技论文, 2014, 9(12): 1340-1343. doi: 10.3969/j.issn.2095-2783.2014.12.003Deng Lijun, Cao Yijun, Wang Lijun. Effect of surface tension on bubble size in frother solutions[J]. China Sciencepaper, 2014, 9(12): 1340-1343. doi: 10.3969/j.issn.2095-2783.2014.12.003 [8] 杨蕾, 徐初阳, 周欢欢, 等. 望峰岗选煤厂煤泥可浮性研究[J]. 洁净煤技术, 2013, 19(6): 5-8, 16. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201306003.htmYang Lei, Xu Chuyang, Zhou Huanhuan, et al. Slime flotability in Wangfenggang coal preparation plant[J]. Clean Coal Technology, 2013, 19(6): 5-8, 16. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201306003.htm [9] 张鸿波, 张涛, 张强. 表面活性剂对难浮煤泥浮选效果的影响[J]. 煤矿机械, 2019, 40(11): 84-86. https://www.cnki.com.cn/Article/CJFDTOTAL-MKJX201911029.htmZhang Hongbo, Zhang Tao, Zhang Qiang. Effect of surface active agent on flotation effect of difficult flotation slime[J]. Coal Mine Machinery, 2019, 40(11): 84-86. https://www.cnki.com.cn/Article/CJFDTOTAL-MKJX201911029.htm [10] 侯鹏辉. 煤泥浮选起泡剂的优化试验[J]. 洁净煤技术, 2012, 18(4): 13-15, 29. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201204006.htmHou Penghui. Optimization test of frother for slime flotation[J]. Clean Coal Technology, 2012, 18(4): 13-15, 29. https://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201204006.htm [11] 郭坤, 赵文婷, 董连平, 等. 聚乙二醇作为煤泥浮选起泡剂的规律研究[J]. 煤炭技术, 2016, 35(9): 298-300. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201609122.htmGuo Kun, Zhao Wenting, Dong Lianping, et al. Regularity of polyethylene glycol as coal slime flotation frothers[J]. Coal Technology, 2016, 35(9): 298-300. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201609122.htm [12] Li N, Yang X D, Gong Y, et al. Enhancing electrical capacitance tomographic sensor design using fuzzy theory based quantifiers[J]. Measurement Science and Technology, 2014, 25(12): 125401. http://adsabs.harvard.edu/abs/2014MeScT..25l5401L [13] Li N, Cao M C, He C F, et al. Multi-parametric indicator design for ECT sensor optimization used in oil transmission[J]. IEEE Sensors Journal, 2017, 17(7): 2074-2088. [14] Fang K T, Lin D K J, Winker P, et al. Uniform design: theory and application[J]. Technometrics, 2000, 42(3): 237-248. http://www.ams.org/mathscinet-getitem?mr=1801031 [15] 李登万, 陈洪涛, 冯锦春, 等. 基于均匀设计法的精密车削参数优化[J]. 机械工程学报, 2015, 51(3): 206-212. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201503031.htmLi Dengwan, Chen Hongtao, Feng Jinchun, et al. Precision cutting parameters optimization based on uniform design method[J]. Journal of Mechanical Engineering, 2015, 51(3): 206-212. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201503031.htm [16] Deng L N, Feng B, Zhang Y.An optimization method for multi-objective and multi-factor designing of a ceramic slurry: Combining orthogonal experimental design with artificial neural networks[J]. Ceramics International, 2018, 44(13): 15918-15923. [17] 王洁, 丁华琼, 桂夏辉. 开滦矿区难选煤泥浮选影响因素研究[J]. 选煤技术, 2012(4): 1-5, 9. https://www.cnki.com.cn/Article/CJFDTOTAL-XMJS201204002.htmWang Jie, Ding Huaqiong, Gui Xiahui. Research on influencing factors of hard flotation tiny coal in Kailuan mining area[J]. Coal Preparation Technology, 2012(4): 1-5, 9. https://www.cnki.com.cn/Article/CJFDTOTAL-XMJS201204002.htm [18] Ping H L, Xu G H, Wu S F.System optimization of cyclohexane dehydrogenation under multiphase reaction conditions using the uniform design method[J]. International Journal of Hydrogen Energy, 2015, 40(46): 15923-15932. http://www.sciencedirect.com/science/article/pii/S0360319915301907 [19] Song G, Xu G Q, Quan Y K, et al. Uniform design for the optimization of Al2O3 nanofilms produced by electrophoretic deposition[J]. Surface and Coatings Technology, 2016, 286: 268-278. http://smartsearch.nstl.gov.cn/paper_detail.html?id=7bef36b1903d58451ca7fc220e2ba63d [20] Yang J, Li L, Yang L Y, et al. Uniform design for the parameters optimization of pin-fins channel heat sink[J]. Applied Thermal Engineering, 2017, 120: 289-297. http://www.sciencedirect.com/science/article/pii/S1359431116337528 [21] Wang H, Zhang L, Li G L, et al. Application of uniform design experimental method in waste cooking oil(WCO)co-hydroprocessing parameter optimization and reaction route investigation[J]. Fuel, 2017, 210: 390-397. http://www.sciencedirect.com/science/article/pii/S0016236117310785 [22] Tsai J T, Yang P Y, Chou J H.Data-driven approach to using uniform experimental design to optimize system compensation parameters for an auto-alignment machine[J]. IEEE Access, 2018, 6: 40365-40378. http://ieeexplore.ieee.org/document/8412479/citations -

下载:

下载: