Study on the gasket durability in the segment joint of subsurface excavated fabricated section

-

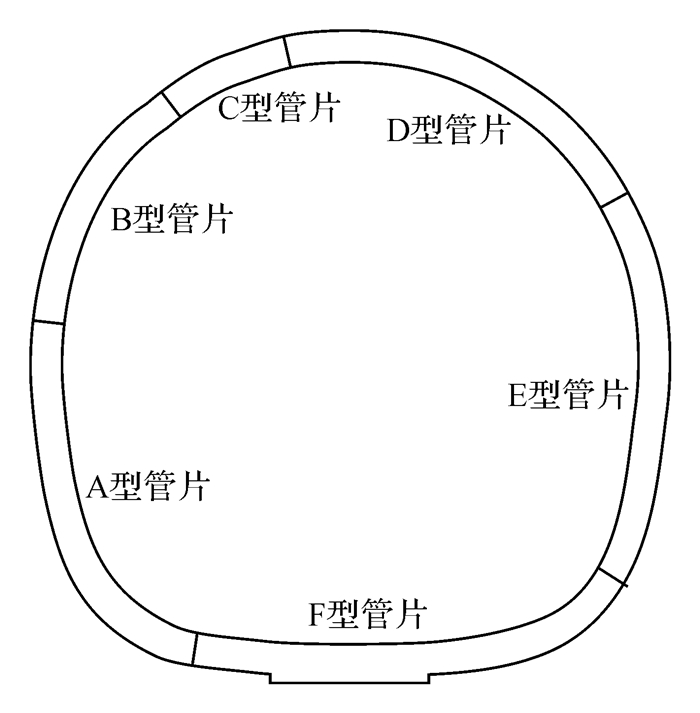

摘要: 橡胶老化会引起材料力学性能改变,进而造成防水失效,针对接缝处密封垫开展老化性能的研究具有重要意义。北京地铁6号线起点-金安桥区间为我国第一条暗挖装配式隧道。隧道采用管片作为二衬结构,以三元乙丙橡胶密封垫作为管片接缝处防水材料。为检验接缝防水是否满足耐久性要求,根据时温等效原理,对密封垫的橡胶材料开展了加速老化试验,预测其使用寿命。针对寿命预测计算流程繁琐,编制相应的程序,解决了数据处理中参数需反复试算的难题。此外,对管片密封垫的应力状态进行了数值模拟,分析了老化对密封垫防水的影响,指出密封垫的设计耐水压力至少提高至原设计水压的1.75倍。Abstract: The aging of rubber will cause changes in the mechanical properties of materials, which in turn will cause waterproof failure.The section from the starting point of Beijing Metro Line 6 to Jin'anqiao is the first fabricated surface excavated tunnel in our country.It is of great significance to study the aging performance of the gaskets at the joints.The tunnel uses segments as the secondary lining structure, and EPDM gaskets as the waterproof material at the segment joints.In order to check whether the waterproof of the joints meets the durability requirements, an accelerated aging test was carried out on the rubber material of the gasket according to time-temperature equivalence principle, which predicts the service life of the rubber material.Due to the cumbersome calculation process of life prediction, the corresponding program was compiled to solve the problem of repeated trial calculation of parameters in the data processing.In addition, a numerical simulation of the stress of segment gaskets was carried out, and the influence of aging on the waterproof of the gasket was analyzed.It was pointed out that the designed water pressure of the gasket was increased to at least 1.75 times of the original one.

-

Key words:

- gasket /

- service life /

- accelerated aging test /

- compression set /

- joint waterproof

-

表 1 不同温度下三元乙丙橡胶密封垫老化特性指标

Table 1. Aging characteristics indexes of EPDM gasket at different temperatures

序号 80 ℃ 90 ℃ 100 ℃ 110 ℃ 120 ℃ t/d yc t/d yc t/d yc t/d yc t/d yc 1 1.00 0.963 1 1.00 0.942 0 1.00 0.922 3 1.00 0.914 1 1.00 0.892 6 2 3.00 0.944 6 3.00 0.921 7 2.00 0.916 7 2.00 0.903 7 2.00 0.873 0 3 6.00 0.935 4 6.00 0.907 0 4.00 0.907 3 4.00 0.873 5 4.00 0.836 6 4 10.00 0.929 0 10.00 0.888 6 7.00 0.883 0 7.00 0.848 0 7.00 0.777 8 5 16.00 0.921 6 16.00 0.878 5 9.25 0.872 7 9.25 0.831 0 9.25 0.746 0 6 23.25 0.904 1 23.25 0.859 1 13.00 0.867 0 13.00 0.800 8 13.00 0. 695 6 7 30.00 0.910 4 30.00 0.853 6 19.00 0.830 5 19.00 0.763 0 19.00 0.648 0 8 36.00 0.899 4 36.00 0.853 6 28.00 0.800 6 28.00 0.723 3 25.00 0.601 3 9 46.00 0.895 8 46.00 0.839 8 38.00 0.777 2 38.00 0.680 8 32.00 0.530 3 10 59.00 0.891 1 59.00 0.820 4 51.00 0.739 7 51.00 0.622 3 44.00 0.448 2 11 77.00 0.879 2 77.00 0.791 9 67.00 0.692 9 67.00 0.556 2 62.00 0.347 3 12 99.00 0.857 2 99.00 0.754 1 84.00 0.665 7 84.00 0.527 9 84.00 0.257 7 13 132.75 0.820 9 132.75 0.730 4 117.75 0.600 2 117.75 0.443 8 117.75 0.148 7 表 2 不同温度下的速度常数K和经验常数B

Table 2. Speed constant K and empirical constant B at different temperatures

温度/℃ 80 90 100 110 120 参数 Ki 0.003 2 0.005 7 0.011 2 0.018 8 0.044 8 Bi 0.951 0 0.929 6 0.932 1 0.923 3 0.973 9 表 3 各参数计算值

Table 3. Calculated value of each parameter

c d $\hat{\sigma}_{e} $ δ 19.627 8 -8 989.5 0.122 2 0.383 6 -

[1] 韩宝明, 陈佳豪, 杨运节, 等. 2019年世界城市轨道交通运营统计与分析综述[J]. 都市快轨交通, 2020, 33(1): 4-8. https://www.cnki.com.cn/Article/CJFDTOTAL-DSKG202001004.htmHan Baoming, Chen Jiahao, Yang Yunjie, et al. Statistical analysis of urban rail transit operation in the world in 2019: a review[J]. Urban Rapid Rail Transit, 2020, 33(1): 4-8. https://www.cnki.com.cn/Article/CJFDTOTAL-DSKG202001004.htm [2] 高楠. 大断面海底盾构隧道管片接缝防水试验研究[D]. 北京: 北京交通大学, 2016. [3] Working Group No.2 I T A.Guidelines for the design of shield tunnel lining[J]. Tunnelling and Underground Space Technology, 2000, 15(3): 303-331. [4] Ding W Q, Gong C J, Mosalam K M, et al. Development and application of the integrated sealant test apparatus for sealing gaskets in tunnel segmental joints[J]. Tunnelling and Underground Space Technology, 2017, 63: 54-68. doi: 10.1016/j.tust.2016.12.008 [5] Gong C J, Ding W Q, Soga K, et al. Failure mechanism of joint waterproofing in precast segmental tunnel linings[J]. Tunnelling and Underground Space Technology, 2019, 84: 334-352. doi: 10.1016/j.tust.2018.11.003 [6] Li X, Zhou S H, Di H G, et al. Evaluation and experimental study on the sealant behaviour of double gaskets for shield tunnel lining[J]. Tunnelling and Underground Space Technology, 2018, 75: 81-89. doi: 10.1016/j.tust.2018.02.004 [7] 朱洺嵚, 丁文其, 金跃郎, 等. 上海市高水压深层排水盾构隧道管片接缝密封垫形式试验研究[J]. 隧道建设, 2017, 37(10): 1303-1308. doi: 10.3973/j.issn.1672-741X.2017.10.014Zhu Mingqin, Ding Wenqi, Jin Yuelang, et al. Experimental study of segment joint sealing gasket forms of deep drainage shield tunnel in Shanghai under high water pressure[J]. Tunnel Construction, 2017, 37(10): 1303-1308. doi: 10.3973/j.issn.1672-741X.2017.10.014 [8] 朱祖熹. 隧道防水的若干创新技术与值得重新认识的几个问题[J]. 中国建筑防水, 2006(1): 55-59. doi: 10.3969/j.issn.1007-497X.2006.01.017Zhu Zuxi. Some innovative techniques of tunnel waterproofing and viewpoints[J]. China Building Waterproofing, 2006(1): 55-59. doi: 10.3969/j.issn.1007-497X.2006.01.017 [9] 陈云尧, 张军伟, 马士伟, 等. 盾构隧道管片密封垫防水失效模式及改善研究[J]. 隧道建设, 2019, 39(6): 946-952. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201906011.htmChen Yunyao, Zhang Junwei, Ma Shiwei, et al. Waterproof failure mode and improvement for sealing gasket of shield tunnel segment[J]. Tunnel Construction, 2019, 39(6): 946-952. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201906011.htm [10] 沈佳佳. 地铁盾构隧道管片接头抗渗与耐久性能演化研究[D]. 长沙: 中南大学, 2014. [11] 刘建国, 陈凯, 刘喜东, 等. 类矩形盾构隧道密封垫耐久性分析[J]. 现代隧道技术, 2016, 53(S1): 158-163. https://www.cnki.com.cn/Article/CJFDTOTAL-XDSD2016S1024.htmLiu Jianguo, Chen Kai, Liu Xidong, et al. Analysis on the seal gasket durability in quasi-rectangular shield tunnels[J]. Modern Tunnelling Technology, 2016, 53(S1): 158-163. https://www.cnki.com.cn/Article/CJFDTOTAL-XDSD2016S1024.htm [12] 门燕青, 李虎, 周建国, 等. 考虑盾构隧道纵向应力松弛的环缝渗漏水计算分析[J]. 土木工程学报, 2019, 52(S1): 99-105. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC2019S1014.htmMen Yanqing, Li Hu, Zhou Jianguo, et al. Calculation of circular joint leakage considering the longitudinal stress relaxation along the shield tunnel[J]. China Civil Engineering Journal, 2019, 52(S1): 99-105. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC2019S1014.htm [13] Tan J S, Shen S L, Zhou A, et al. Laboratory data on long-term sealing behaviors of two water-swelling materials for shield tunnel gasket[J]. Data in Brief, 2020, 30: 105609. doi: 10.1016/j.dib.2020.105609 [14] 伍振志. 越江盾构隧道耐久性若干关键问题研究[D]. 上海: 同济大学, 2008. [15] 丁杨, 孟伟, 邓文武. 盾构管片橡胶密封垫断面形式设计及耐久性研究[J]. 华东交通大学学报, 2016, 33(4): 45-49. doi: 10.3969/j.issn.1005-0523.2016.04.007Ding Yang, Meng Wei, Deng Wenwu. Study on durability and section design of sealing rubber pad of shield segment[J]. Journal of East China Jiaotong University, 2016, 33(4): 45-49. doi: 10.3969/j.issn.1005-0523.2016.04.007 [16] 张家奇, 顾贇, 黄昕, 等. 盾构隧道防水密封垫长期服役性能预测的室内试验研究[J]. 现代隧道技术, 2018, 55(S2): 751-757. https://www.cnki.com.cn/Article/CJFDTOTAL-XDSD2018S2097.htmZhang Jiaqi, Gu Yun, Huang Xin, et al. Experimental study on prediction of the long-term serviceability of waterproof gasket for shield tunnels[J]. Modern Tunnelling Technology, 2018, 55(S2): 751-757. https://www.cnki.com.cn/Article/CJFDTOTAL-XDSD2018S2097.htm [17] 张子新, 张家奇, 黄昕, 等. 盾构隧道密封垫长期防水性能预测的试验研究[J]. 浙江大学学报: 工学版, 2020, 54(1): 118-125. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC202001014.htmZhang Zixin, Zhang Jiaqi, Huang Xin, et al. Experimental study on prediction of long-term durability of sealing gasket of shield tunnel[J]. Journal of Zhejiang University: Engineering Science, 2020, 54(1): 118-125. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC202001014.htm [18] 姚润樾. 预制拼装综合管廊管片接缝橡胶密封垫的长期性能与截面优化研究[D]. 广州: 华南理工大学, 2019. [19] 莫一婷. 盾构隧道衬砌接头的构造与耐久性的研究[D]. 上海: 同济大学, 2007. [20] 伍振志, 杨林德, 季倩倩, 等. 越江盾构隧道防水密封垫应力松弛试验研究[J]. 建筑材料学报, 2009, 12(5): 539-543. doi: 10.3969/j.issn.1007-9629.2009.05.008Wu Zhenzhi, Yang Linde, Ji Qianqian, et al. Experimental study on stress relaxation of waterproof gasket of river-crossing shield tunnel[J]. Journal of Building Materials, 2009, 12(5): 539-543. doi: 10.3969/j.issn.1007-9629.2009.05.008 [21] 张稳军, 丁超, 张成平, 等. 不同错台量对复合型密封垫影响及长期防水预测[J]. 隧道建设, 2020, 40(3): 337-345. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD202003005.htmZhang Wenjun, Ding Chao, Zhang Chengping, et al. Influence of different dislocation amount on composite sealing gasket and long-term waterproofing performance prediction[J]. Tunnel Construction, 2020, 40(3): 337-345. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD202003005.htm [22] Barbero E J, Julius M J.Time-temperature-age viscoelastic behavior of commercial polymer blends and felt filled polymers[J]. Mechanics of Advanced Materials and Structures, 2004, 11(3): 287-300. doi: 10.1080/15376490490427252 [23] 樊庆功, 方卫民, 苏许斌. 盾构隧道遇水膨胀橡胶密封垫止水性能试验研究[J]. 地下空间, 2002(4): 335-338, 372. doi: 10.3969/j.issn.1673-0836.2002.04.013Fan Qinggong, Fang Weimin, Su Xubin. Experimental study on the waterproof capability of the hydro-expansive rubber sealing cushion in shield tunnel[J]. Underground Space, 2002(4): 335-338, 372. doi: 10.3969/j.issn.1673-0836.2002.04.013 [24] 李咏今. 橡胶老化性能变化或寿命预测的计算方法[J]. 合成橡胶工业, 1989, 12(3): 205-209. https://www.cnki.com.cn/Article/CJFDTOTAL-HCXF198903023.htmLi Yongjin. The calculation methods for predicting the aging property change of life-period of rubber[J]. Synthetic Rubber Industry, 1989, 12(3): 205-209. https://www.cnki.com.cn/Article/CJFDTOTAL-HCXF198903023.htm [25] 赵亚溥. 近代连续介质力学[M]. 北京: 科学出版社, 2016: 183-184. [26] Boyce M C, Arruda E M.Constitutive models of rubber elasticity: a review[J]. Rubber Chemistry and Technology, 2000, 73(3): 504-523. doi: 10.5254/1.3547602 [27] 金日光, 华幼卿. 高分子物理[M]. 北京: 化学工业出版社, 2011: 169-171. [28] 王伟, 邓涛, 赵树高. 橡胶Mooney-Rivlin模型中材料常数的确定[J]. 特种橡胶制品, 2004, 25(4): 8-10. doi: 10.3969/j.issn.1005-4030.2004.04.003Wang Wei, Deng Tao, Zhao Shugao. Determination for material constants of rubber mooney-rivlin model[J]. Special Purpose Rubber Products, 2004, 25(4): 8-10. doi: 10.3969/j.issn.1005-4030.2004.04.003 [29] Gent A N.Engineering with rubber[M]. München: Carl Hanser Verlag GmbH & Co.KG, 2012. [30] 李拼, 谢宏明, 何川, 等. 基于有效接触应力的大张开量盾构隧道密封垫防水性能分析[J]. 隧道建设, 2019, 39(12): 1993-1999. doi: 10.3973/j.issn.2096-4498.2019.12.009Li Pin, Xie Hongming, He Chuan, et al. Waterproof performance analysis of water sealing gasket of large open shield tunnel based on effective contact stress[J]. Tunnel Construction, 2019, 39(12): 1993-1999. doi: 10.3973/j.issn.2096-4498.2019.12.009 [31] 王泓颖, 鲜晴羽, 刘大刚, 等. 盾构法施工荷载对小半径曲线隧道管片防水性能的影响研究[J]. 隧道建设, 2019, 39(9): 1453-1460. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201909015.htmWang Hongying, Xian Qingyu, Liu Dagang, et al. Influence of shield tunneling construction load on waterproofing performance of small radius curved tunnel segments[J]. Tunnel Construction, 2019, 39(9): 1453-1460. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201909015.htm -

下载:

下载: