Investigation on the ultimate load bearing capacity of U-shaped steel arch support in coal bursting mine

-

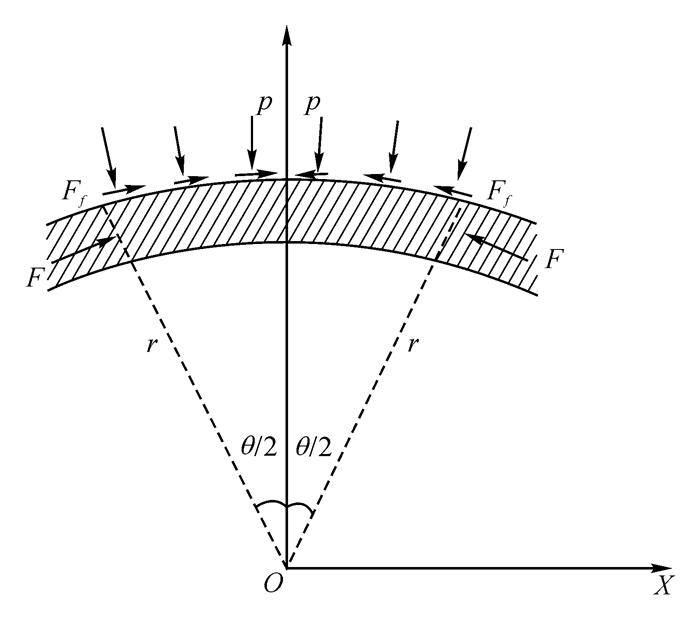

摘要: 煤矿巷道围岩的冲击破坏程度与支护形式密切相关,探究冲击地压矿井巷道U型钢的极限承载能力,是研究深部煤炭资源安全开采的重要课题,对矿井冲击地压的防治具有重要意义。本文以义马煤田典型冲击地压矿井为工程背景,建立均匀围压条件下U型钢支护变形的力学模型,给出U型钢变形量的解析解,对比分析均匀和不均匀荷载作用下U型钢和巷道的变形规律,研究了荷载增加时U型钢支护可承受的上覆岩层极限荷载和极限埋深。通过现场监测巷道不同U型钢支护条件下顶底板移近量、移近速度的变化,分析了提高U型钢承载能力来控制巷道变形和冲击地压的机理。研究结果表明:随着荷载增加,巷道变形量和应变能均将出现一个急剧加速点,该点可用来确定应用U型钢支护的极限埋深均匀荷载下为1 600 m,非均匀荷载下为1 400 m,当达到极限埋深时,U型钢将完全处于失效状态,巷道变形激增;在冲击地压矿井巷道进行U型钢支护设计时,改善围岩支护接触条件、对U型钢边界施加均匀荷载,对提高U型钢的支护性能具有重要作用。采用承载能力更大的U型钢支护方式能吸收更多来自围岩释放的能量,对巷道顶底板移近量的控制较为稳定,使得巷道变形无法瞬间激增,保证巷道的稳定性,实现对巷道冲击地压的有效控制。Abstract: The damage degree of the surrounding rock in the coal mine roadway is closely related to the support form, thus to carry out research on the ultimate bearing capacity of U-shaped steel support in coal bursting mine is of important guiding significance for the prevention and control of coal burst.Taking a typical coal bursting mine in Yima Coalfield as the engineering background, a theoretical calculation mechanical model of U-shaped steel deformation under uniform loading is established and the analytical solution of the overall deformation is given, then deformation of U-shaped steel and roadway under the action of uniform and non-uniform load is compared, and the affordable ultimate load from overlying strata and applicable ultimate depth of U-shaped steel support is studied when the load increases.The change of approach amount and speed of the roadway roof and floor through on-site monitoring is obtained, and improving the bearing capacity of U-shaped steel support to control the deformation of roadway and coal burst is analyzed.The results show that: with the increase of load, there will be a sharp acceleration point in the deformation and strain energy of roadway, which can be used to determine the applicable ultimate depth of U-shaped steel support.The applicable ultimate depth of U-shaped steel under uniform loading is 1 600 m, and the value is 1 600 m under the non-uniform loading.When the ultimate depth is reached, U-shaped steel will be completely in failure state, and the deformation of roadway will increase rapidly.When designing U-shaped steel support for the roadway of coal bursting mine, it is very important to improve the contact condition of surrounding rock support and apply uniform load to the U-shaped steel support boundary to ensure good contact between surrounding rock and U-shaped steel, and improve the bearing capacity of U-shaped steel.U-shaped steel support with greater bearing capacity can absorb more energy released from surrounding rocks, and better control the approach amount between the roof and floor of the roadway, preventing the deformation of the roadway from increasing rapidly, thus the stability of the roadway is ensured and the coal burst in the roadway is effectively controlled.

-

Key words:

- U-shaped steel arch /

- ultimate depth /

- bearing capacity /

- roadway deformation /

- strain energy

-

表 1 U型钢截面参数表

Table 1. The cross-section parameters of U-shaped steel arch

型号 横截面尺寸/mm 横截面面积/cm2 惯性矩/cm4 横截面弯曲模量/cm3 抗拉强度/MPa 屈服强度/MPa B1 B2 B3 B4 H Iy Wx Wx Wy 25U 135.0 101.5 40.0 47.0 120.0 31.79 495.81 551.97 79.77 81.77 530 335 29U 150.5 116.0 44.0 53.0 124.0 37.00 612.00 771.00 92.00 102.00 530 335 36U 171.0 128.0 50.5 60.5 138.0 45.69 928.65 1 244.75 128.55 145.59 530 350 40U 171.0 128.5 50.5 60.5 141.9 51.02 1 064.07 1 366.98 141.22 159.94 580 390 表 2 数值模拟中U型钢截面参数表

Table 2. Parameters of U-shaped steel arch in the numerical simulation

类型 杨氏模量/GPa 泊松比 横截面面积/cm2 惯性矩/cm3 Ix Iy 25U 200 0.3 31.79 495.81 551.97 29U 200 0.3 37.00 612.00 771.00 36U 200 0.3 45.69 928.65 1 244.75 40U 200 0.3 51.02 1 064.07 1 366.98 表 3 数值模型中岩层物理力学参数

Table 3. Mechanical parameters of rock strata used for numerical model

杨氏模量/GPa 泊松比 抗压强度/MPa 抗拉强度/MPa 内聚力 摩擦角 剪胀角/(°) 初始值/MPa 软化率/% 残值/MPa 初始值/(°) 软化率/% 残值/(°) 7.13 0.25 4.0 0.04 3.06 5 0.306 36.0 0.5 30.0 6.0 表 4 理论计算与数值模拟对比

Table 4. Comparison between theoretical calculation and numerical simulation

围压/MPa 36U型钢变形量/mm 40U型钢变形量/mm 理论值 模拟值 理论值 模拟值 15.0 73 70 68 65 17.5 89 85 82 78 20.0 97 94 89 86 22.5 110 106 101 97 25.0 115 112 109 104 27.5 124 120 115 112 30.0 136 131 127 123 32.5 149 145 141 138 35.0 171 168 160 155 -

[1] 齐庆新, 李一哲, 赵善坤, 等. 我国煤矿冲击地压发展70年: 理论与技术体系的建立与思考[J]. 煤炭科学技术, 2019, 47(9): 1-40. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201909001.htmQi Qingxin, Li Yizhe, Zhao Shankun, et al. Seventy years development of coal mine rockburst in China: establishment and consideration of theory and technology system[J]. Coal Science and Technology, 2019, 47(9): 1-40. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201909001.htm [2] 姜耀东, 潘一山, 姜福兴, 等. 我国煤炭开采中的冲击地压机理和防治[J]. 煤炭学报, 2014, 39(2): 205-213. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201402001.htmJiang Yaodong, Pan Yishan, Jiang Fuxing, et al. State of the art review on mechanism and prevention of coal bumps in China[J]. Journal of China Coal Society, 2014, 39(2): 205-213. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201402001.htm [3] 潘一山. 煤矿冲击地压扰动响应失稳理论及应用[J]. 煤炭学报, 2018, 43(8): 2091-2098. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201808001.htmPan Yishan. Disturbance response instability theory of rockburst in coal mine[J]. Journal of China Coal Society, 2018, 43(8): 2091-2098. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201808001.htm [4] 刘德军, 左建平, 刘海雁, 等. 我国煤矿巷道支护理论及技术的现状与发展趋势[J]. 矿业科学学报, 2020, 5(1): 22-33. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX202001003.htmLiu Dejun, Zuo Jianping, Liu Haiyan, et al. Development and present situation of support theory and technology in coal mine roadway in China[J]. Journal of Mining Science and Technology, 2020, 5(1): 22-33. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX202001003.htm [5] 徐连满, 潘威翰, 潘一山, 等. O型棚支护抵抗冲击地压等级计算方法[J]. 煤炭学报, 2020, 45(10): 3408-3417. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202010005.htmXu Lianman, Pan Weihan, Pan Yishan, et al. Calculation method of rock burst resistance grade of O-shaped shed support[J]. Journal of China Coal Society, 2020, 45(10): 3408-3417. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202010005.htm [6] 曾祥华, 徐连满, 潘一山. "U"型钢支架搭接处力学性能[J]. 辽宁工程技术大学学报: 自然科学版, 2016, 35(9): 955-960. https://www.cnki.com.cn/Article/CJFDTOTAL-FXKY201609011.htmZeng Xianghua, Xu Lianman, Pan Yishan. Mechanical properties of U-shaped steel stent overlap part[J]. Journal of Liaoning Technical University: Natural Science, 2016, 35(9): 955-960. https://www.cnki.com.cn/Article/CJFDTOTAL-FXKY201609011.htm [7] Jiao Y Y, Song L, Wang X Z, et al. Improvement of the U-shaped steel sets for supporting the roadways in loose thick coal seam[J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 60: 19-25. doi: 10.1016/j.ijrmms.2012.12.038 [8] 张守宝, 李政, 王宇, 等. 煤泥岩硐室群区巷道底鼓控制机理及应用[J]. 应用基础与工程科学学报, 2017, 25(4): 712-723. https://www.cnki.com.cn/Article/CJFDTOTAL-YJGX201704006.htmZhang Shoubao, Li Zheng, Wang Yu, et al. Floor heave control technology of ingate surrounding with coal and soft mudstone in chamber group[J]. Journal of Basic Science and Engineering, 2017, 25(4): 712-723. https://www.cnki.com.cn/Article/CJFDTOTAL-YJGX201704006.htm [9] Li W T, Yang N, Li T C, et al. A new approach to simulate the supporting arch in a tunnel based on improvement of the beam element in FLAC3D[J]. Journal of Zhejiang University-SCIENCE A, 2017, 18(3): 179-193. doi: 10.1631/jzus.A1600508 [10] Barla G, Bonini M, Semeraro M.Analysis of the behaviour of a yield-control support system in squeezing rock[J]. Tunnelling and Underground Space Technology, 2011, 26(1): 146-154. doi: 10.1016/j.tust.2010.08.001 [11] Mitri H S, Khan U H.Design guidelines for steel arch supports in underground mining[J]. Mining Science and Technology, 1991, 13(1): 37-44. doi: 10.1016/0167-9031(91)90226-3 [12] 尤春安. U型钢可缩性支架的稳定性分析[J]. 岩石力学与工程学报, 2002, 21(11): 1672-1675. doi: 10.3321/j.issn:1000-6915.2002.11.019You Chun'an. Stability analysis of U-steel yieldable support[J]. Chinese Journal of Rock Mechanics and Engineering, 2002, 21(11): 1672-1675. doi: 10.3321/j.issn:1000-6915.2002.11.019 [13] 陈辉, 姜耀东, 邓代新, 等. 断层带软弱围岩变形特征及支护优化研究[J]. 矿业科学学报, 2018, 3(6): 543-552. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX201806005.htmChen Hui, Jiang Yaodong, Deng Daixin, et al. Study on deformation characteristics and support optimization of weak surrounding rock in fault zone[J]. Journal of Mining Science and Technology, 2018, 3(6): 543-552. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX201806005.htm [14] Rotkegel M.Pw steel arch support-designing and test results[J]. Journal of Sustainable Mining, 2013, 12(1): 34-40. doi: 10.7424/jsm130107 [15] 李晓斌, 何富连, 秦宾宾, 等. 极近距离煤层回采巷道围岩分类与支护研究[J]. 矿业科学学报, 2020, 5(3): 325-333. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX202003011.htmLi Xiaobin, He Fulian, Qin Binbin, et al. Study on classification and support of surrounding rock of mining roadway in extremely close coal seams[J]. Journal of Mining Science and Technology, 2020, 5(3): 325-333. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX202003011.htm [16] Rodríguez R, Díaz-Aguado M B.Deduction and use of an analytical expression for the characteristic curve of a support based on yielding steel ribs[J]. Tunnelling and Underground Space Technology, 2013, 33: 159-170. doi: 10.1016/j.tust.2012.07.006 [17] Zhang K, Zhang G M, Hou R B, et al. Stress evolution in roadway rock bolts during mining in a fully mechanized longwall face, and an evaluation of rock bolt support design[J]. Rock Mechanics and Rock Engineering, 2015, 48(1): 333-344. doi: 10.1007/s00603-014-0546-4 [18] Wang C, Wang Y, Lu S.Deformational behaviour of roadways in soft rocks in underground coal mines and principles for stability control[J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37(6): 937-946. http://www.sciencedirect.com/science/article/pii/S1365160900000265 [19] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. GB/T 4697—2008矿山巷道支护用热轧U型钢[S]. 北京: 中国标准出版社, 2009. [20] Itasca Consulting Group Inc. FLAC3D(Fast Lagrangian Analysis of Continua in 3 Dimensions)[M]. Minneapolis, Minnesota, USA, 2006 [21] 孔祥松, 单仁亮, 肖禹航, 等. 钢管混凝土支架作用下南关矿煤巷变形破坏规律[J]. 矿业科学学报, 2020, 5(2): 160-168. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX202002004.htmKong Xiangsong, Shan Renliang, Xiao Yuhang, et al. Deformation and failure law of coal roadway supported by concrete filled steel tube supports in Nanguan mine[J]. Journal of Mining Science and Technology, 2020, 5(2): 160-168. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX202002004.htm [22] Duncan Fama M E, Trueman R, Craig M S.Two-and three-dimensional elasto-plastic analysis for coal pillar design and its application to highwall mining[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1995, 32(3): 215-225. http://www.sciencedirect.com/science/article/pii/0148906294000455 [23] Hoek E.Estimating Mohr-Coulomb friction and cohesion values from the Hoek-Brown failure criterion[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1990, 27(3): 227-229. http://www.sciencedirect.com/science/article/pii/014890629094333O [24] Wang H W, Poulsen B A, Shen B T, et al. The influence of roadway backfill on the coal pillar strength by numericalinvestigation[J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(3): 443-450. http://www.sciencedirect.com/science/article/pii/S1365160910001772 [25] 姜耀东, 王宏伟, 赵毅鑫, 等. 极软岩回采巷道互补控制支护技术研究[J]. 岩石力学与工程学报, 2009, 28(12): 2383-2390. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200912004.htmJiang Yaodong, Wang Hongwei, Zhao Yixin, et al. Study of complementary supporting technology of extremely soft rock mining roadway[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(12): 2383-2390. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200912004.htm [26] 谢和平, 周宏伟, 薛东杰, 等. 煤炭深部开采与极限开采深度的研究与思考[J]. 煤炭学报, 2012, 37(4): 535-542. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201204002.htmXie Heping, Zhou Hongwei, Xue Dongjie, et al. Research and consideration on deep coal mining and critical mining depth[J]. Journal of China Coal Society, 2012, 37(4): 535-542. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201204002.htm [27] 张科学. 构造与巨厚砾岩耦合条件下回采巷道冲击地压机理研究[D]. 北京: 中国矿业大学(北京), 2015. -

下载:

下载: