Research on monitoring of moving ferromagnetic objects in open-pit mine crushing station based on low-frequency eddy current detection

-

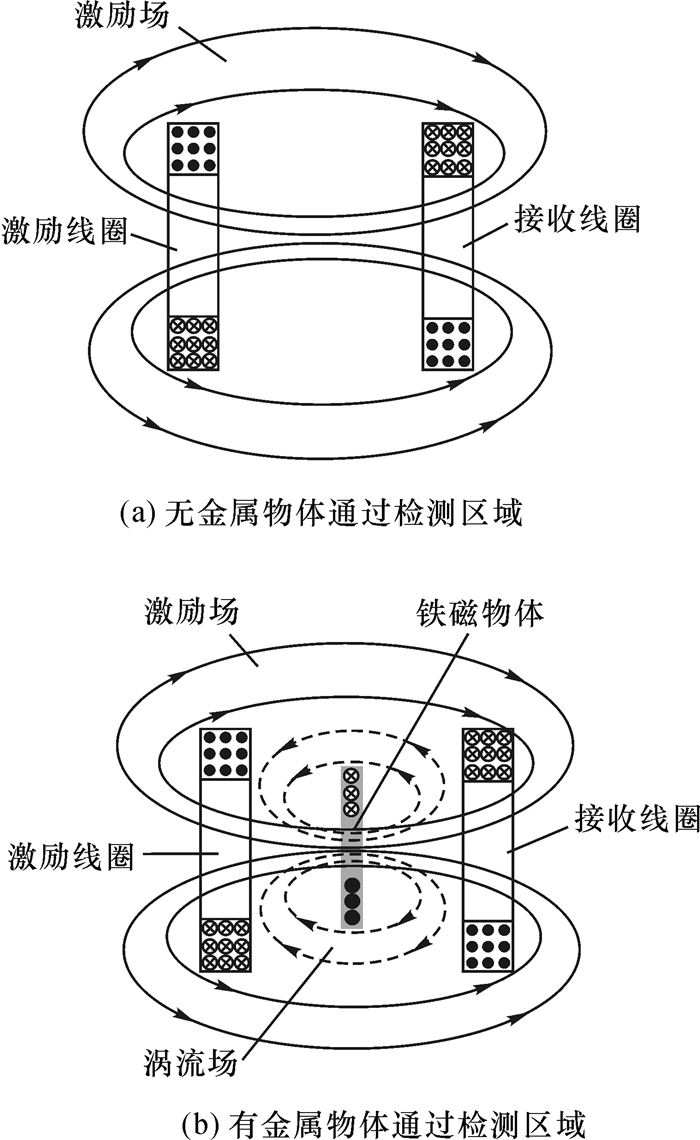

摘要: 在露天煤矿生产作业过程中,采掘及运输时脱落的电铲配件、铁板等较大铁磁物体随煤块进入破碎机,将导致破碎机卡死、破碎齿损坏、电机烧毁等严重生产事故。本文基于低频涡流检测原理可检测出铁磁性物体的特点,开展了露天矿二级破碎站运动铁磁物体监测研究;以SANDVIK的CR610/14—35双齿辊式筛分式破碎机为实验对象,依据电磁互感原理对检测系统的机理进行解析建模。建模及实验的结果表明:由于强背景噪声的存在,铁磁物体产生的涡流信号属于微弱信号,通过对检测探头进行参数的优化设计和对被检测物路径的合理规划,可有效地提高信噪比;根据实验对象特点,在金属物半径与检测距离之比为0.048,检测探头的线圈半径与检测距离比值为0.044 5时具有最大的信噪比;在1~35 kHz的频段,低频段信噪比要高于高频段信噪比;垂直于检测轴线进入检测区域的路径相比平行于检测轴线进入检测区域的路径的初始值和响应时间更具有明显优势。Abstract: In the process of open-pit coal mine production, mining and transport loss of excavator accessories, iron and other large ferromagnetic objects with the coal into the crusher, will result in crusher jammed, broken tooth damage and even motor burn down and other serious production accidents, based on the principle of low frequency eddy current detection can effectively detect ferromagnetic objects, the characteristics of the ferromagnetic objects open-pit mine secondary crushing plant movement monitoring research. Taking SANDVIK's CR610/14—35 double-tooth roller sieve crusher as the experimental object, the mechanism of the detection system was analytically modeled according to the principle of electromagnetic mutual induction. The results of modeling and experiments show that the eddy current generated by ferromagnetic objects is weak due to the existence of strong background noise. The signal to noise ratio(SNR)can be improved by optimizing the parameters of the detector and planning the path of the detector. According to the characteristics of the experimental object, the maximum SNR was obtained when the ratio of the radius of the metal to the detection distance was 0.048, and the ratio of the coil radius to the detection distance was 0.044 5. In the 1~35 kHz segment, the SNR is higher in the low frequency band than the high frequency band. The initial value and response time of the path entering the detection area perpendicular to the detection axis have obvious advantages over the path entering the detection area parallel to the axis.

-

表 1 铁磁物体运动参数

Table 1. Motion parameters of the detected object

运动参数 数值 板式给料机速度/(m·s-1) 0.30 板式给料机倾角/(°) 21 物体离开给料机瞬时速度/(m·s-1) 0.28 物体落入破碎口瞬时速度/(m·s-1) 7.41 表 2 不同尺寸线圈实验记录

Table 2. Experimental records of different coil size

接收线圈尺寸/mm 幅值变化量Δ 150 1 392 200 1 983 250 1 872 表 3 不同路径的实验参数

Table 3. Experimental parameters of different paths

路径 幅值变化量Δ 到达峰值用时/s v1方向 -v1方向 ±v1方向

v2方向34.11 9.44 11.01

1.0150.2 -

[1] 郑友毅. 我国露天煤矿半连续开采工艺的应用和发展策略[J]. 煤炭学报, 2011, 36(5): 756-761. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201105010.htmZheng Youyi. Application and development strategy of semi-continuous mining technology in underground open pit mine[J]. Journal of China Coal Society, 2011, 36(5): 756-761. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201105010.htm [2] 陈树召. 大型露天煤矿他移式破碎站半连续工艺系统优化与应用研究[J]. 煤炭学报, 2012, 37(3): 533-534. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201203032.htmChen Shuzhao. Optimization and application research on semi-continuous technology system with mobile crusher in large open pit coal mines[J]. Journal of China Coal Society, 2012, 37(3): 533-534. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201203032.htm [3] 祁星鑫, 王晓军, 黎艳, 等. 新疆主要煤区煤矸石的特征研究及其利用建议[J]. 煤炭学报, 2010, 35(7): 1197-1201. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201007032.htmQi Xingxin, Wang Xiaojun, Li Yan, et al. Study on properties of the coal gangues from Xinjiang main coal mine regions and their utilization suggestions[J]. Journal of China Coal Society, 2010, 35(7): 1197-1201. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201007032.htm [4] 刘煜, 郑群飞. 基于离散元素法的双齿辊破碎机影响因素研究[J]. 矿业科学学报, 2018, 3(4): 364-370. http://www.cnki.com.cn/Article/CJFDTotal-KYKX201804007.htmLiu Yu, Zheng Qunfei. Study on influencing factors of double-toothed roller crusher based on discrete element method[J]. Journal of Mining Science and technology, 2018, 3(4): 364-370. http://www.cnki.com.cn/Article/CJFDTotal-KYKX201804007.htm [5] 邹雨君, 田慕琴, 乔建强, 等. 基于时频图像的齿辊式破碎机中电机轴承故障特征提取方法[J]. 煤炭学报, 2018, 43(S2): 623-633. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2018S2034.htmZou Yujun, Tian Muqin, Qiao Jianqiang, et al. Bearing fault feature extraction of roller crusher motor based on time-frequency image[J]. Journal of China Coal Society, 2018, 43(S2): 623-633. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2018S2034.htm [6] 戴惠新, 郝先耀, 赵志强. 除铁器应用现状及其发展方向[J]. 金属矿山, 2007(9): 90-93. doi: 10.3321/j.issn:1001-1250.2007.09.025Dai Huixin, Hao Xianyao, Zhao Zhiqiang. Status-quo of tramp-iron remover application and its development trend[J]. Metal Mine, 2007(9): 90-93. doi: 10.3321/j.issn:1001-1250.2007.09.025 [7] Javier G M, Jaime G G, Ernesto V S.Non-destructive techniques based on eddy current testing[J]. Sensors, 2011, 11(3): 2525-2565. doi: 10.3390/s110302525 [8] Lei Yinzhao. General series expression of eddy-current impedance for coil placed above multi-layer plate conductor[J]. Chinese Physics B, 2018(6): 060308-060314. http://www.cnki.com.cn/Article/CJFDTotal-ZGWL201806024.htm [9] 雷银照. 关于电磁场解析方法的一些认识[J]. 电工技术学报, 2016, 31(19): 11-25. doi: 10.3969/j.issn.1000-6753.2016.19.002Lei Yinzhao. Reviews of analytical methods for electromagnetic fields[J]. Transactions of China Electrotechnical Society, 2016, 31(19): 11-25. doi: 10.3969/j.issn.1000-6753.2016.19.002 [10] 康建宁. 煤的电导率随地应力变化关系的研究[J]. 河南理工大学学报: 自然科学版, 2005, 24(6): 430-433. doi: 10.3969/j.issn.1673-9787.2005.06.004Kang Jianning. Study on the relationship between coal conductivity and earth stress[J]. Journal of Henan Polytechnic University: Natural Science, 2005, 24(6): 430-433. doi: 10.3969/j.issn.1673-9787.2005.06.004 [11] Fan M, Huang P, Ye B, et al. Analytical modeling for transient probe response in pulsed eddy current testing[J]. NDT & E International, 2009, 42(5): 376-383. http://www.sciencedirect.com/science/article/pii/S0963869509000085 [12] Su Y P, Liu X, Hui S Y R.Mutual inductance calculation of movable planar coils on parallel surfaces[J]. IEEE Transactions on Power Electronics, 2009, 24(4): 1115-1123. doi: 10.1109/TPEL.2008.2009757 [13] Conway J T.Inductance calculations for noncoaxial coils using bessel functions[J]. IEEE Transactions on Magnetics, 2007, 43(3): 1023-1034. doi: 10.1109/TMAG.2006.888565 [14] Brighton M, English M J.Calculation of optimum spacing for a three coil axially symmetric metal detector[J]. Electronics Letters, 1993, 29(10): 838-839. doi: 10.1049/el:19930560 [15] Grover, F W.Tables for the calculation of the mutual inductance of any two coaxial single-layer coils[J]. Proceedings of the Ire, 1933, 21(7): 1039-1049. doi: 10.1109/JRPROC.1933.227836 [16] Grover F W.The calculation of the inductance of single-layer coils and spirals wound with wire of large cross section[J]. Proceedings of the Ire, 1929, 17(11): 2053-2063. doi: 10.1109/JRPROC.1929.221624 [17] Babic S, Sirois F, Akyel C, et al. Mutual inductance calculation between circular filaments arbitrarily positioned in space: alternative to grover's formula[J]. IEEE Transactions on Magnetics, 2010, 46(9): 3591-3600. doi: 10.1109/TMAG.2010.2047651 -

下载:

下载: