Experimental study on CO generation law of coal left in goaf in shallow-buried comprehensive and mechanized coal mining face

-

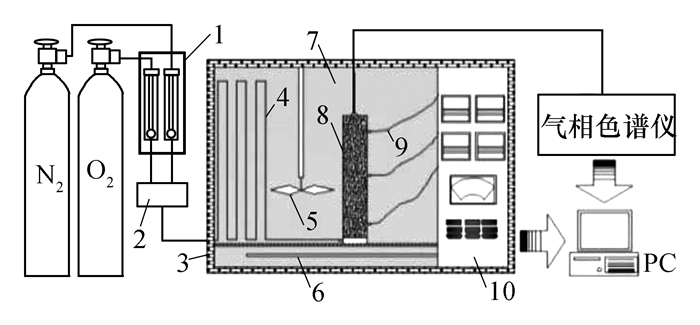

摘要: 为探究浅埋综采面采空区遗煤氧化过程中的CO产生规律,本文以高家梁矿浅埋煤层为研究对象,与阳泉矿深埋煤层相对比,利用油浴升温氧化系统对高家梁矿不同煤层的综采工作面煤样和阳泉矿煤样进行了升温氧化实验。研究表明:高家梁矿浅埋深各煤样在低温40 ℃时消耗O2产生CO体积分数达到1×10-4;各煤样在氧化升温过程中的耗氧速率、CO产生速率和放热强度随温度升高逐渐增加;高家梁矿浅埋深煤样产生了40 ℃和130 ℃两个临界温度,分别对应加速氧化反应起点和剧烈氧化反应起点,而阳泉矿深埋煤层煤样只有一个不明显临界温度,且相对滞后,达100 ℃~120 ℃;在相同煤温下,高家梁矿浅埋深各煤样CO产生量和产生速率、O2的消耗量和消耗速率均明显大于阳泉矿深埋煤层;高家梁矿浅埋深各煤层比阳泉矿煤层更早进入加速氧化阶段,且所需温度更低。可见,煤层埋藏越浅,升温氧化时煤的耗氧速率和CO产生速率越快,升温对浅埋深煤样的氧化放热促进作用更强。Abstract: In order to explore the law of CO generation in the oxidation process of coal leftover in shallow-buried comprehensive and mechanized mining areas, This article takes the shallow coal seam Gaojialiang Mine as the research object, and compares it with the deep coal seam Yangquan mine. Using the oil bath temperature-raising oxidation system, a temperature-increasing oxidation test was carried out on the coal samples of the fully mechanized coal mining face in different coal seams of Gaojialiang Mine and Yangquan Mine. Research shows: Each coal sample in the shallow-buried Gaojialiang Mine consumes O2 at a low temperature of 40 ℃ to produce CO volume fraction of 1×10-4; The oxygen consumption rate, CO production rate and heat release intensity of each coal sample during the oxidation and heating process gradually increase with the increase of temperature; The coal sample of the shallow-buried Gaojialiang Mine produced two critical temperatures of 40 ℃ and 130 ℃, corresponding to the starting point of accelerated oxidation reaction and the starting point of violent oxidation reaction, respectively. However, the Yangquan coal sample in the deep-buried coal seam has only one insignificant critical temperature, and relatively lagging behind, reaching 100 ℃~120 ℃. At the same coal temperature, the CO production and production rate of each coal seam in the shallow-buried Gaojialiang Mine, and the consumption and consumption rate of O2 in each coal seam are significantly greater than those of the deep-buried coal seam in Yangquan Mine. The coal seams of the shallow-buried Gaojialiang Mine enter the accelerated oxidation stage earlier than Yangquan coal seams, and the required temperature is lower. The shallower the coal seam is buried, the faster the coal's oxygen consumption rate and CO production rate during heating oxidation., The increase in temperature promotes the oxidation exotherm of coal samples at shallow depths more strongly.

-

Key words:

- goaf /

- shallow buried /

- leftover coal oxidation /

- CO production law /

- oil bath heating oxidation /

- critical temperature

-

表 1 采集煤样信息

Table 1. Collected coal sample information

矿井名称 采样煤层 煤层埋深/m 高家梁矿 2-2中煤层 196 3-1煤层 229 4-2中煤层 278 阳泉矿 15煤层 <1 200 -

[1] 梁国栋, 郭建. 我国煤矿瓦斯事故原因统计分析[J]. 能源与环保, 2018, 40(11): 75-78. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZMT201811017.htmLiang Guodong, Guo Jian. Statistical analysis of the causes of coal mine gas accidents in my country[J]. Energy and Environmental Protection, 2018, 40(11): 75-78. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZMT201811017.htm [2] Zhou Lihong, Luo Yi. Improvement and upgrade of mine fire simulation program MFIRE[J]. Journal of Coal Science & Engineering, 2011, 17(3): 275-280. doi: 10.1007/s12404-011-0309-8 [3] 崔芳鹏, 武强, 林元惠, 等. 中国煤矿水害综合防治技术与方法研究[J]. 矿业科学学报, 2018, 3(3): 219-228. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX201803002.htmCui Fangpeng, Wu Qiang, Lin Yuanhui, et al. Research on comprehensive prevention technology and methods of coal mine water hazards in China[J]. Journal of Mining Science, 2018, 3(3): 219-228. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX201803002.htm [4] 张晓阳. 煤矿顶板事故成因分析及防治措施[J]. 内蒙古煤炭经济, 2017(19): 81-82. https://www.cnki.com.cn/Article/CJFDTOTAL-LMMT201719049.htmZhang Xiaoyang. Cause analysis and prevention measures of coal mine roof accidents[J]. Inner Mongolia Coal Economy, 2017(19): 81-82. https://www.cnki.com.cn/Article/CJFDTOTAL-LMMT201719049.htm [5] 王月红, 周宁, 张九零, 等. 不同煤种自燃指标气体优化研究[J]. 河南理工大学学报: 自然科学版, 2020, 39(6): 10-15. https://www.cnki.com.cn/Article/CJFDTOTAL-JGXB202006002.htmWang Yuehong, Zhou Ning, Zhang Jiuling, et al. Research on the optimization of spontaneous combustion index gases for different coal types[J]. Journal of Henan Polytechnic University: Natural Science Edition, 2020, 39(6): 10-15. https://www.cnki.com.cn/Article/CJFDTOTAL-JGXB202006002.htm [6] 罗海珠, 钱国胤. 煤种自然发火标志气体指标研究[J]. 煤矿安全, 2003, 34(1): 86-89. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ2003S1020.htmLuo Haizhu, Qian Guoyin. Research on the gas index of coal spontaneous ignition[J]. Coal Mine Safety, 2003, 34(1): 86-89. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ2003S1020.htm [7] 邓军, 徐精彩, 陈晓坤. 煤自燃机理及预测理论研究进展[J]. 辽宁工程技术大学学报, 2003(4): 455-459. doi: 10.3969/j.issn.1008-0562.2003.04.009Deng Jun, Xu Jingcai, Chen Xiaokun. Research progress of coal spontaneous combustion mechanism and prediction theory[J]. Journal of Liaoning Technical University, 2003(4): 455-459. doi: 10.3969/j.issn.1008-0562.2003.04.009 [8] 国家安全生产监督管理总局, 国家煤矿安全监察局. 煤矿安全规程[M]. 北京: 煤炭工业出版社, 2016. [9] 周铭轩, 胡社荣, 于新智, 等. 综采工作面CO超限的主要影响因素及防控方法[J]. 煤矿安全, 2018, 49(4): 165-167, 172. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201804043.htmZhou Mingxuan, Hu Sherong, Yu Xinzhi, et al. Main influencing factors and prevention methods of CO overrun in fully mechanized coal mining face[J]. Coal Mine Safety, 2018, 49(4): 165-167, 172. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201804043.htm [10] 张德鹏, 王志刚, 孙勇, 等. 我国煤矿CO超限研究现状及趋势[J]. 煤矿安全, 2013, 44(4): 183-185. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201304058.htmZhang Depeng, Wang Zhigang, Sun Yong, et al. Current status and trends of research on CO overrun in coal mines in my country[J]. Coal Mine Safety, 2013, 44(4): 183-185. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201304058.htm [11] 王连聪, 孙勇, 冯文彬, 等. 煤层开采中CO产生及来源规律现场实验研究[J]. 煤矿安全, 2014, 45(12): 43-45, 50. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201412012.htmWang Liancong, Sun Yong, Feng Wenbin, et al. Field test research on CO generation and source law in coal mining[J]. Coal Mine Safety, 2014, 45(12): 43-45, 50. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201412012.htm [12] 关万里. 补连塔综采面回风隅角CO体积分数变化分析[J]. 能源技术与管理, 2013, 38(3): 43-45. https://www.cnki.com.cn/Article/CJFDTOTAL-JSMT201303015.htmGuan Wanli. Analysis of CO volume fraction change at the return air corner of fully mechanized coal mining face of Bulianta[J]. Energy Technology and Management, 2013, 38(3): 43-45. https://www.cnki.com.cn/Article/CJFDTOTAL-JSMT201303015.htm [13] 蒋志刚. 灵武矿区采煤工作面CO产生机理及变化规律研究[D]. 西安: 西安科技大学, 2009. [14] 谭波, 程刚, 朱晓曼, 等. 煤层钻孔作业时CO产生规律的实验研究[J]. 矿业科学学报, 2020, 5(3): 263-271. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX202003003.htmTan Bo, Cheng Gang, Zhu Xiaoman, et al. Experimental research on CO generation law during coal seam drilling operations[J]. Journal of Mining Science and Technology, 2020, 5(3): 263-271. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX202003003.htm [15] 秦跃平, 宋宜猛, 杨小彬, 等. 粒度对采空区遗煤氧化速率影响的实验研究[J]. 煤炭学报, 2010, 35(S1): 132-135. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2010S1030.htmQin Yueping, Song Yimeng, Yang Xiaobin, et al. Experimental study on the effect of particle size on the oxidation rate of coal left in goaf[J]. Journal of China Coal Society, 2010, 35(S1): 132-135. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2010S1030.htm [16] 杨小彬, 王逍遥, 周世禄, 等. 基于改进广义回归神经网络的工作面低氧预测模型研究[J]. 矿业科学学报, 2019, 4(5): 434-440. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX201905008.htmYang Xiaobin, Wang Xiaoyao, Zhou Shilu, et al. Research on working face hypoxia prediction model based on improved generalized regression neural network[J]. Journal of Mining Science and Technology, 2019, 4(5): 434-440. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKX201905008.htm [17] 王凤双, 杨胜强, 李珍宝, 等. 不同粒径煤样低温氧化过程升温速率规律研究[J]. 煤炭科学技术, 2014, 42(5): 62- 64. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201405020.htmWang Fengshuang, Yang Shengqiang, Li Zhenbao, et al. Study on the law of heating rate of coal samples with different particle diameters during low temperature oxidation[J]. Coal Science and Technology, 2014, 42(5): 62-64. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201405020.htm [18] 李宗翔, 刘宇, 吴邦大, 等. 基于封闭耗氧实验的窒熄带氧临界体积分数研究[J]. 煤炭学报, 2017, 42(7): 1776-1781. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201707017.htmLi Zongxiang, Liu Yu, Wu Bangda, et al. Study on the critical volume fraction of suffocated oxygen in closed oxygen consumption experiment[J]. Journal of China Coal Society, 2017, 42(7): 1776-1781. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201707017.htm [19] 邓军, 张宇轩, 赵婧昱, 等. 基于程序升温的不同粒径煤氧化活化能实验研究[J]. 煤炭科学技术, 2019, 47(1): 214-219. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201901066.htmDeng Jun, Zhang Yuxuan, Zhao Jingyu, et al. Experimental study on oxidation activation energy of coals with different particle sizes based on temperature programming[J]. Coal Science and Technology, 2019, 47(1): 214-219. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201901066.htm [20] 陈兴, 余明高, 马智会, 等. 粒径对煤氧化升温进程影响的实验研究[J]. 河南理工大学学报: 自然科学版, 2019, 38(4): 25-31. https://www.cnki.com.cn/Article/CJFDTOTAL-JGXB201904004.htmChen Xing, Yu Minggao, Ma Zhihui, et al. Experimental research on the effect of particle size on coal oxidation temperature rise process[J]. Journal of Henan University of Science and Technology: Natural Science Edition, 2019, 38(4): 25-31. https://www.cnki.com.cn/Article/CJFDTOTAL-JGXB201904004.htm [21] 陆伟, 王德明, 周福宝, 等. 绝热氧化法研究煤的自燃特性[J]. 中国矿业大学学报, 2005, 34(2): 213-217. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD200502018.htmLu Wei, Wang Deming, Zhou Fubao, et al. Study on spontaneous combustion characteristics of coal by adiabatic oxidation[J]. Journal of China University of Mining & Technology, 2005, 34(2): 213-217. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD200502018.htm [22] 唐军. 山西省重点煤矿区煤层气开发单元划分——以晋城和阳泉矿区为例[D]. 徐州: 中国矿业大学, 2018. [23] 陈晓坤, 易欣, 邓军. 煤特征放热强度的实验研究[J]. 煤炭学报, 2005, 30(5): 623-626. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200505017.htmChen Xiaokun, Yi Xin, Deng Jun. Experimental study on the characteristic heat release intensity of coal[J]. Journal of China Coal Society, 2005, 30(5): 623-626. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200505017.htm -

下载:

下载: